Axial compensation reinforced connection structure of ultralow temperature compensator

A technology of axial compensation and connection structure, applied in the direction of hose connection device, expansion compensation device for pipeline, pipe/pipe joint/pipe fitting, etc. The effect of improving weld fusion, enhancing weld joint strength and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below according to accompanying drawing.

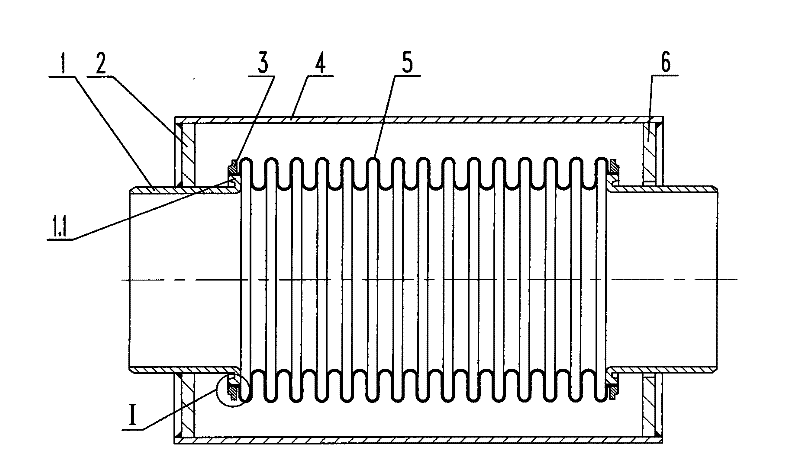

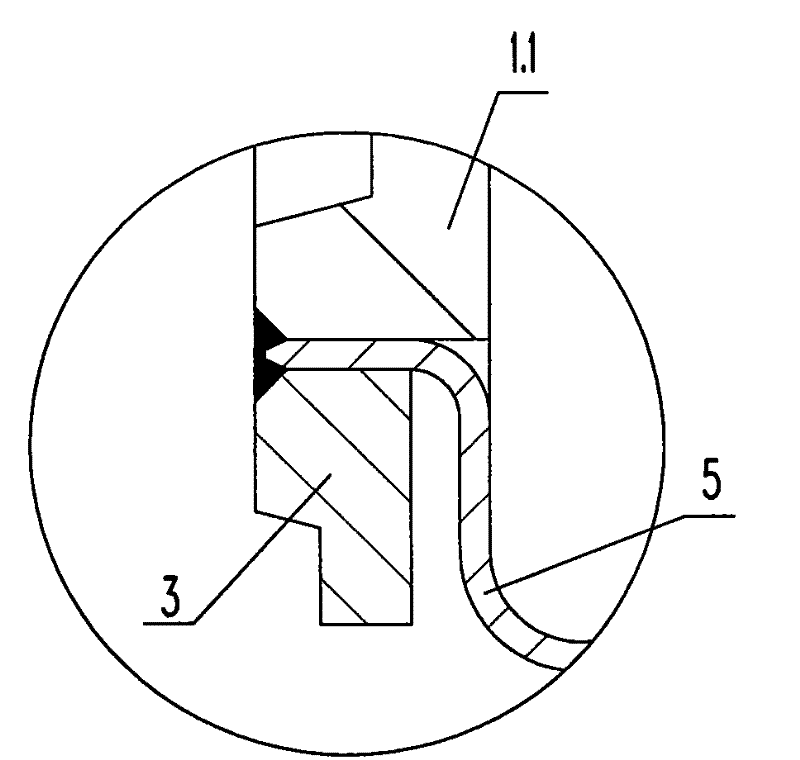

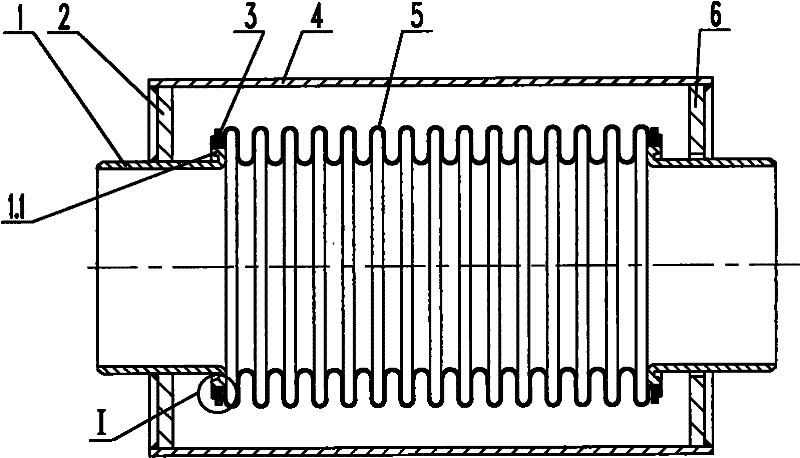

[0013] attached figure 1 The shown cryogenic compensator axially compensates and strengthens the connecting structure, which is set in a shell composed of a circular tubular shell 4, a left end cover 2, and a right end cover 6. The axial compensation strengthening connection structure is composed of a corrugated pipe 5 and a connecting pipe 1 with both ends sealed. The middle section of the connecting pipe 1 at the left end is fixedly connected with the left end cap 2, and the connecting pipe 1 at the right end is matched with the inner hole of the right end cap 6. This structure makes the bellows 5 move axially with the left end cap 2 as the base point. In the present invention, by improving the connection structure between the bellows 5 and the connecting pipes 1 at both ends, structurally, the flanging of the thin-walled bellows 5 is placed between two equal-thickness members,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com