Digital control hydraulic brake type plate shearing machine

A shearing machine and hydraulic technology, which is applied in the direction of shearing machine equipment, shearing devices, metal processing equipment, etc., can solve the problems of low shearing precision of the shearing machine, manual control error, and affecting the production efficiency of the shearing machine. The effect of improving cutting accuracy and cutting efficiency and eliminating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

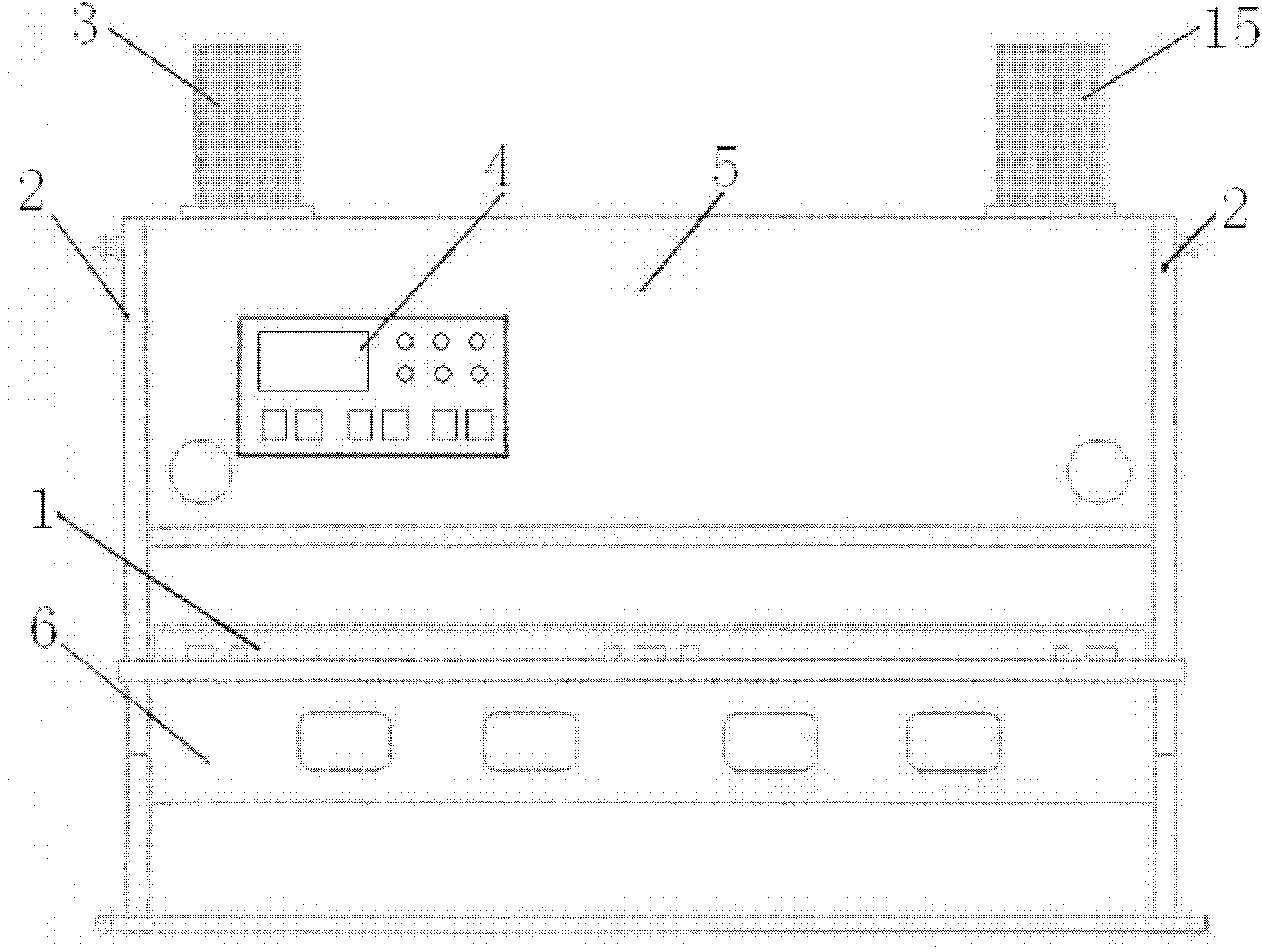

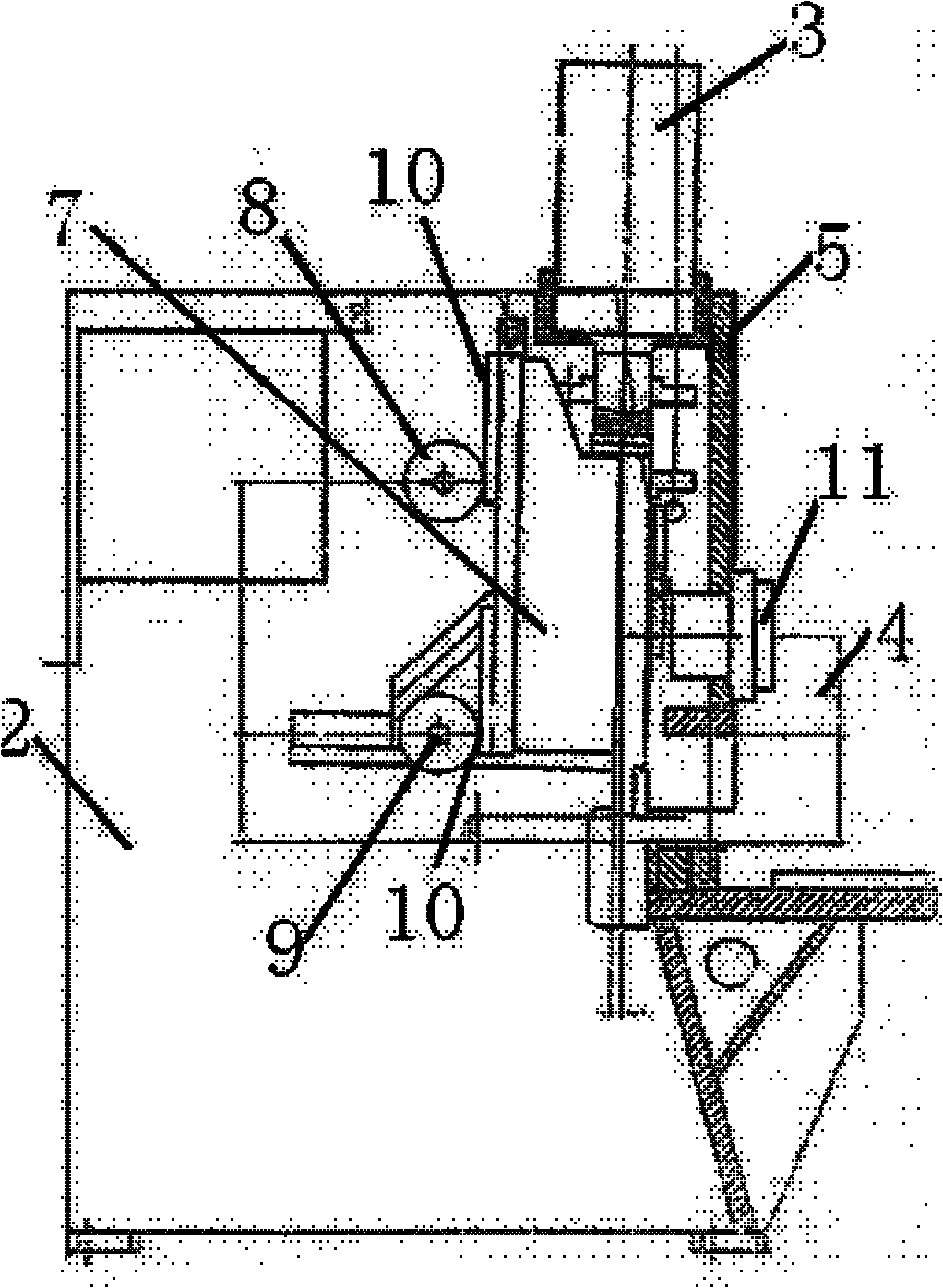

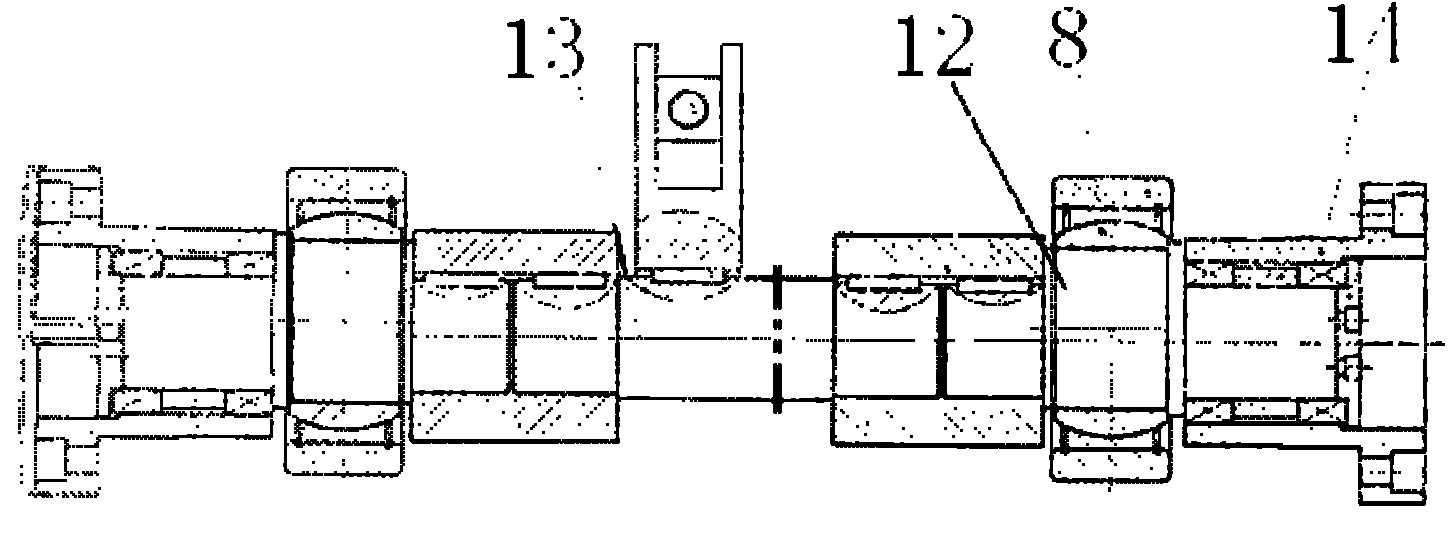

[0021] Such as figure 1 , figure 2 As shown, a numerical control hydraulic gate type shearing machine of the present invention comprises a frame 1, an upper knife rest 7, a lower knife rest 6, drives the upper knife rest 7 to reciprocate and can adjust the angle adjustment of the upper knife rest 7 angles device, stopper device, and tool rest gap adjustment device, and the shearing machine also includes a CNC numerical control system to realize the automatic control of the shearing machine. Connect to control each device, eliminate errors caused by manual operation, and improve the cutting accuracy and cutting efficiency of the shearing machine. The CNC numerical control system includes a control panel 4 located on the front panel 5 of the shearing machine. An LCD display and a key input module are arranged on the control panel 4. Through the key input module, the items to be set are selected, such as the opening of the shearing machine Or close, the number of workpieces to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com