Automatic plant sampling device and using method thereof

An automatic sampling device, plant technology, applied in sampling devices, sampling, measuring devices, etc., can solve the problems of plant tissue contacting external air, freely adjusting slice thickness, unfavorable detection work, etc., to improve sampling efficiency, reduce pollution, Cleverly designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

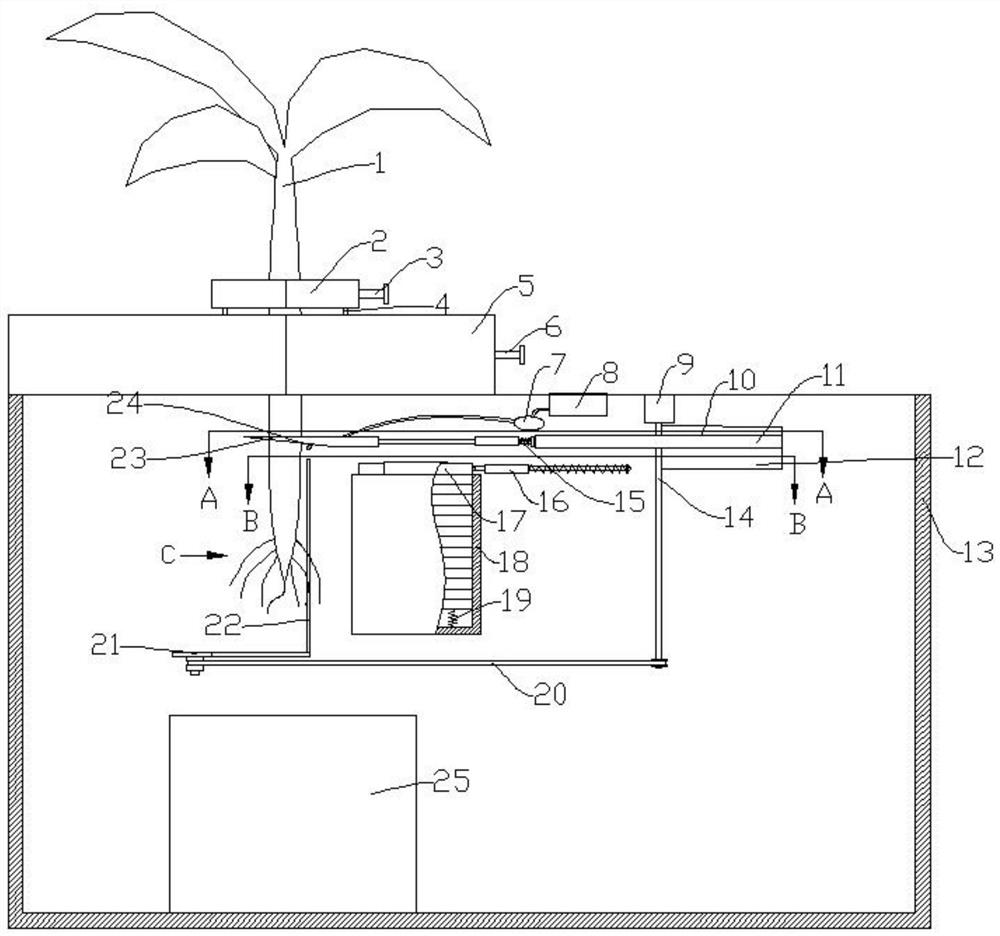

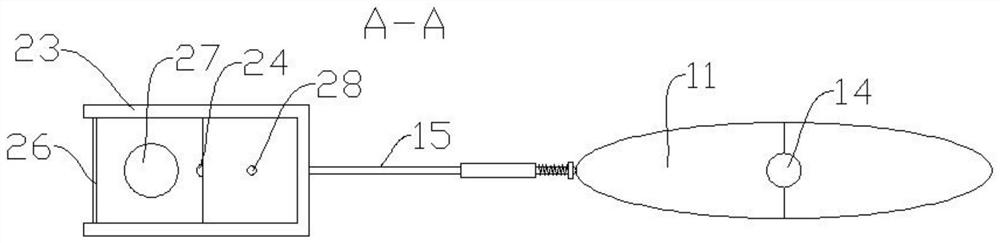

[0036] Reference attached Figure 1-6 , the present embodiment proposes a device for collecting plant tissue slices, including a sampling box 13, the sampling box 13 is fixedly connected with a lower jaw 5, the lower jaw 5 is slidably connected with a lower clamping plate, and the lower clamping plate is rotatably connected with a lower clamping plate. Jaw bar 6, the lower jaw bar 6 is threadedly connected with the lower jaw 5.

[0037] Therefore, when the lower jaw rod 6 rotates, it can drive the lower clamping plate to move in a direction close to the plant 1 without causing the lower clamping plate to rotate, thereby facilitating the mutual cooperation of the lower clamping plate and the lower jaw 5 to realize plant growth. 1 clamping work.

[0038]An upper jaw 2 is also arranged above the lower jaw 5, and the upper jaw 2 is slidably connected with an upper clamping plate 201, and the upper clamping plate 201 is rotatably connected with an upper jaw rod 3, and the upper ja...

Embodiment 2

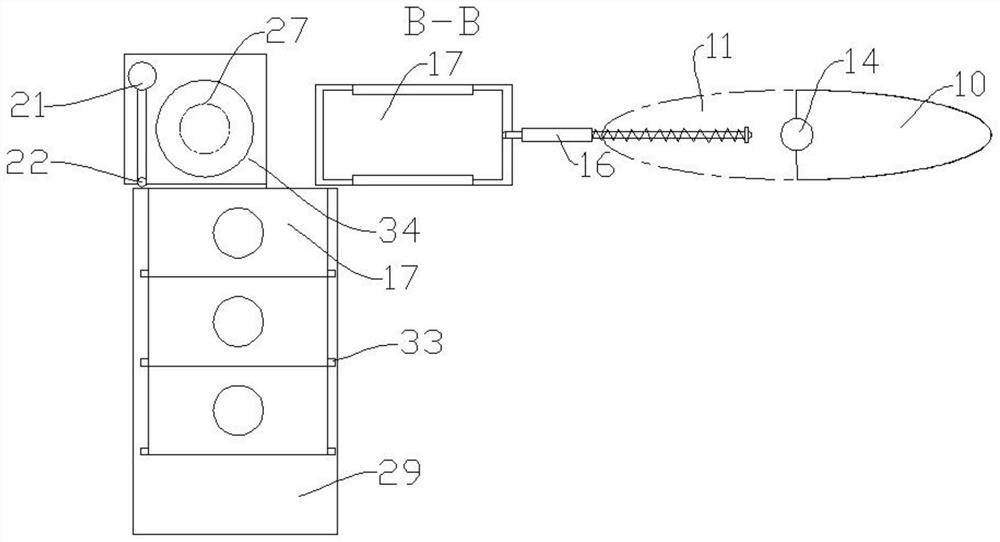

[0066] like Figure 1-6 As shown, the other structures are the same as in Embodiment 1, the difference is that in this embodiment, the sampling box 13 is fixedly connected with a cover glass box arranged above the conveyor belt 29, and several covers are arranged in the cover glass box. Glass slide 30, one side of the cover glass box is provided with an opening for the cover glass 30 to pass through; the bottom end of the cover glass box is slidably connected with a cover glass dial 31 adapted to the cover glass push rod 33, and the cover glass The dial 31 is connected to the inner wall of the cover glass box through the cover glass spring 32 , and the cover glass dial 31 is arranged on one side of the cover glass 30 . The other side of the conveyor belt 29 is provided with a collection box 35 . ,

[0067] In the initial state, the cover glass spring 32 is in a free stretch state, so the cover glass spring 32 will not drive the cover glass dial 31 to move. When the cover gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com