lost foam casting method

A technology of lost foam and sand box, which is applied in casting molding equipment, molds, mold components, etc., can solve problems such as affecting production progress, reducing work efficiency, and cutting devices not being able to continuously perform cutting work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in further detail below by means of specific embodiments:

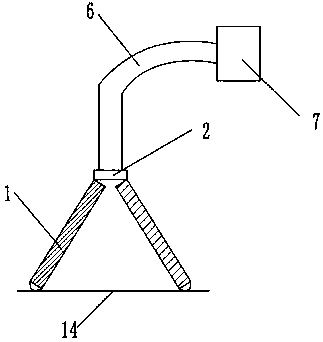

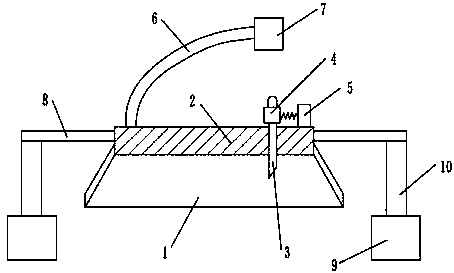

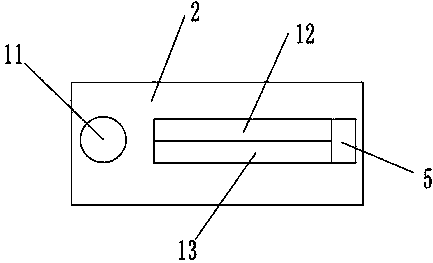

[0019] The reference signs in the accompanying drawings include: baffle plate 1, cover plate 2, blade 3, magnet 4, electromagnet 5, suction pipe 6, suction pump 7, bracket 8, cylinder 9, piston rod 10, suction port 11. A first flexible board 12 , a second flexible board 13 , and a plastic film 14 .

[0020] A kind of casting method of lost foam in this scheme, comprises the following steps:

[0021] 1) Install the sand box: place the special sand box on the three-dimensional vibration table.

[0022] 2) Fill in the bottom sand: The bottom cloth of the sand box is covered with a layer of dry sand with a thickness of about 100mm. The sand is silica sand, the silica content in the silica sand is 90%, and the particle size of the silica sand is 0.450mm. Vibrate and scrape.

[0023] 3) Put in the foam plastic gasification mold: place the foam plastic gasification mold brushe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com