Aluminium hard foil for battery collector

A technology of aluminum hard foil and battery set, which is applied in the direction of battery electrodes, electrode carriers/current collectors, secondary batteries, etc., can solve the problems of working line stop, foil breaking, and low elongation rate, so as to prevent the production line Stop, prevent foil breakage, excellent elongation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

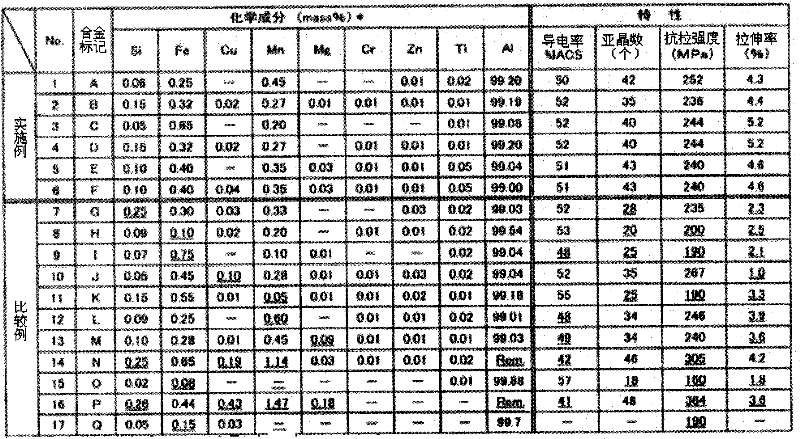

[0077] As mentioned above, the form for carrying out this invention was demonstrated. Hereinafter, a concrete description will be given by comparing Examples that achieve the effects of the present invention and Comparative Examples that do not satisfy the conditions of the present invention. In addition, this invention is not limited to this Example.

[0078] (for test material production)

[0079] (Example No.1-6, Comparative Example No.7-16)

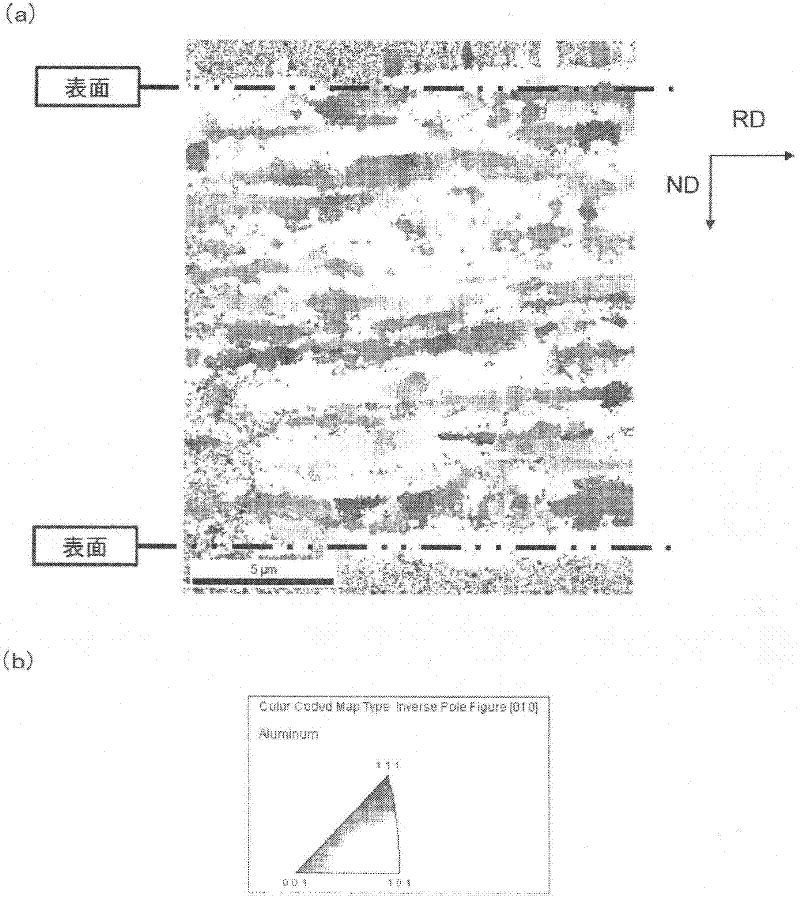

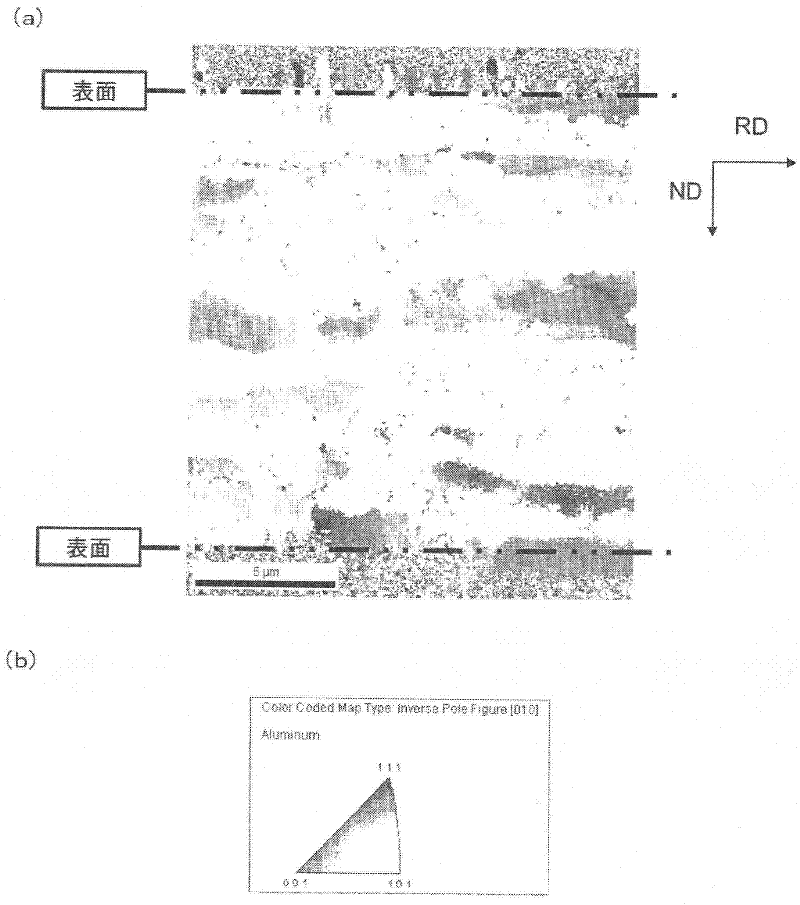

[0080] Aluminum having the composition shown in Table 1 was melted and cast as an ingot, and the ingot was face-cut, and then subjected to a homogenization heat treatment at 540° C. for 4 hours. The homogenized ingot was hot-rolled and then cold-rolled, then intermediate annealed, and then single-roll rolled to a thickness of 15 μm to form an aluminum foil. The conditions of the intermediate annealing are annealing temperature of 450° C. in a continuous annealing furnace, heating rate of 10° C. / s, cooling rate of 20° C. / s, and hold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com