System and method for recycling waste heat of cooling circulated water of air compression station

A technology of cooling circulating water and cooling cycle, which is applied in the direction of liquid variable capacity machinery, variable capacity pump components, machines/engines, etc., which can solve the waste of energy and water resources, waste of waste heat of cooling circulating water, and large power consumption of cooling towers As well as water replenishment and other issues, the energy saving effect is remarkable and the effect of saving coal consumption is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

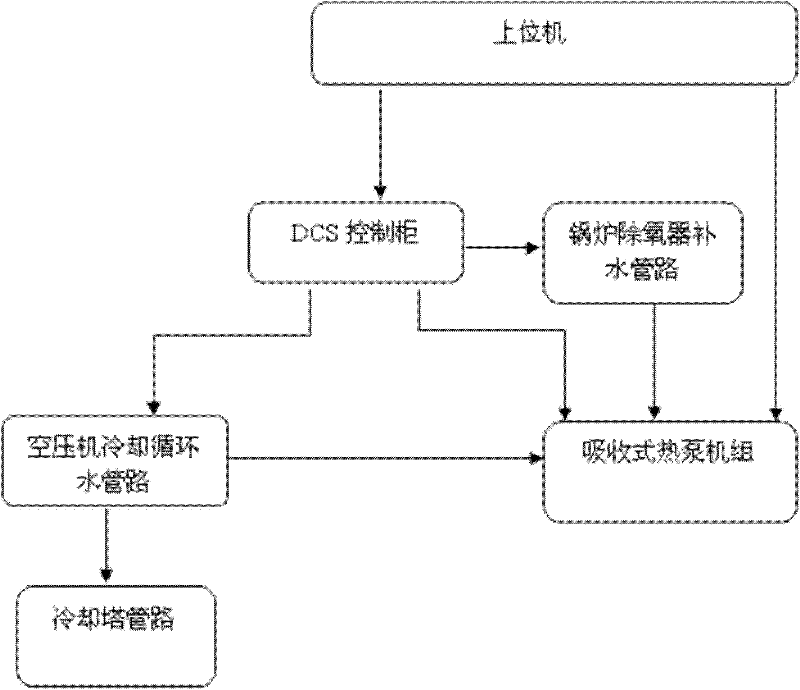

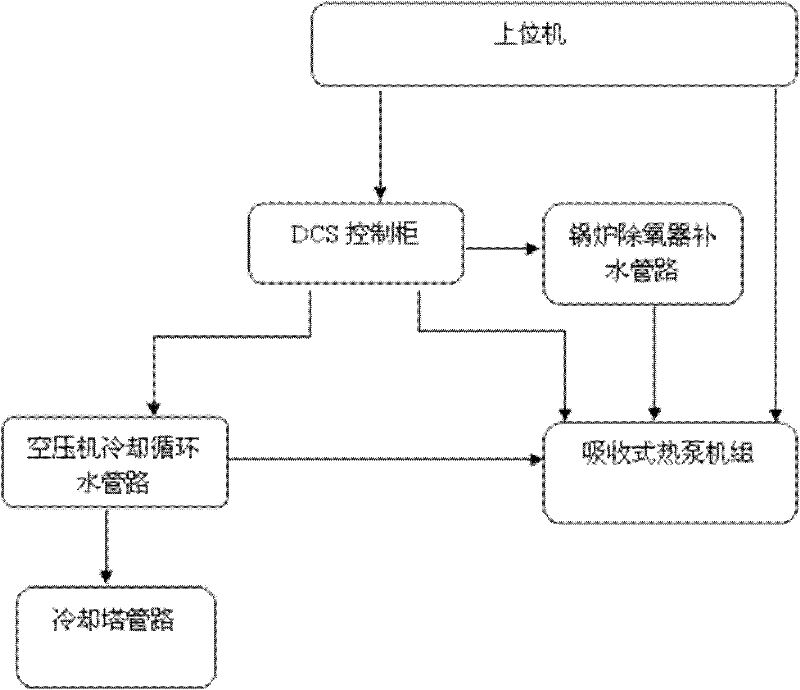

[0020] figure 1 Shown is a schematic structural diagram of the cooling circulating water waste heat recovery and utilization system of the air compressor station according to the present invention. The cooling circulating water waste heat recovery system of the air compressor station includes a host computer, a DCS control cabinet connected to the host computer, and the DCS The air compressor cooling circulating water pipeline, the boiler deaerator water supply pipeline, and the absorption heat pump unit connected to the control cabinet respectively; the absorption heat pump unit is also connected to the host computer; the absorption heat pump unit is also connected through the heat source water pipe The pipeline is connected with the air compressor cooling circulating water pipeline, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com