Resin molding rubber mold, resin molding device, and resin molding method

A technology for resin molding and rubber molds, which is applied in the fields of rubber molds for resin molding, resin molding devices and resin molding. It can solve the problems of severe thermal aging and achieve the effects of improving dimensional accuracy, simple structure, and stable dimensional accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

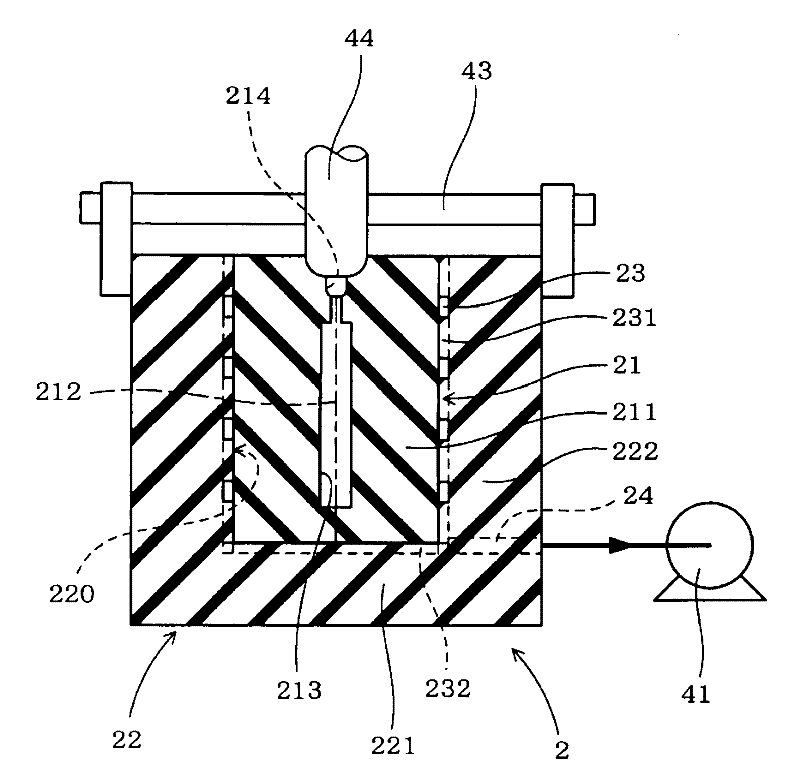

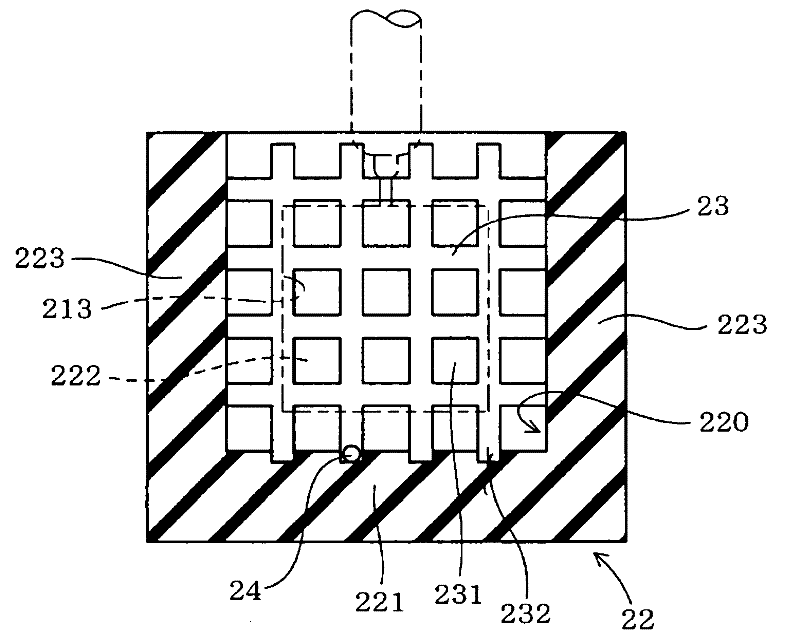

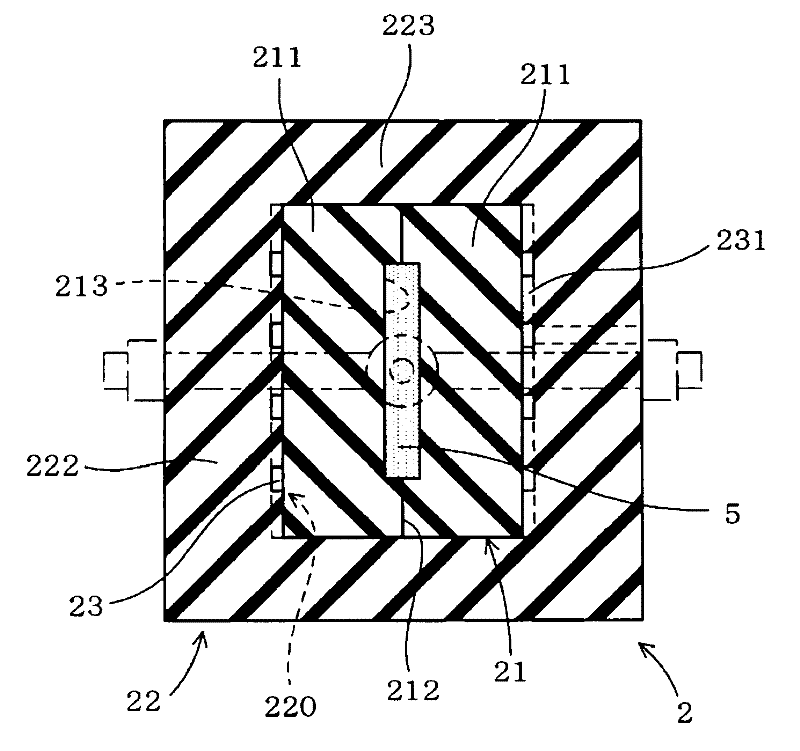

[0077] Next, embodiments of the rubber mold for resin molding, the resin molding apparatus, and the resin molding method of the present invention will be described with reference to the drawings.

[0078] Such as Figure 1 to Figure 4 As shown, the rubber mold 2 for resin molding of this example forms a cavity 213 for pressurizing and filling the thermoplastic resin 5 in a molten state. The rubber mold 2 is composed of a core box 21 made of a rubber material and forming a cavity 213 and a base mold 22 made of a rubber material and having a structure 220 in which the core box 21 is disposed. shape. The core box 21 combines a plurality of divided mold parts 211 (a pair of divided mold parts 211 in this example) on a parting surface 212 for opening a cavity 213 . The base model 22 has at least a lower surface portion 221 and a pair of first side surfaces 222 erected from two opposite sides of the lower surface portion 211, and the pair of first side surfaces 222 are formed on a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com