Inwards-concave metal plate unit based on plane curtain wall external hanging

A metal plate, concave technology, applied in the direction of walls, building components, building insulation materials, etc., can solve the problems of small size, poor adaptability, insufficient keel force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

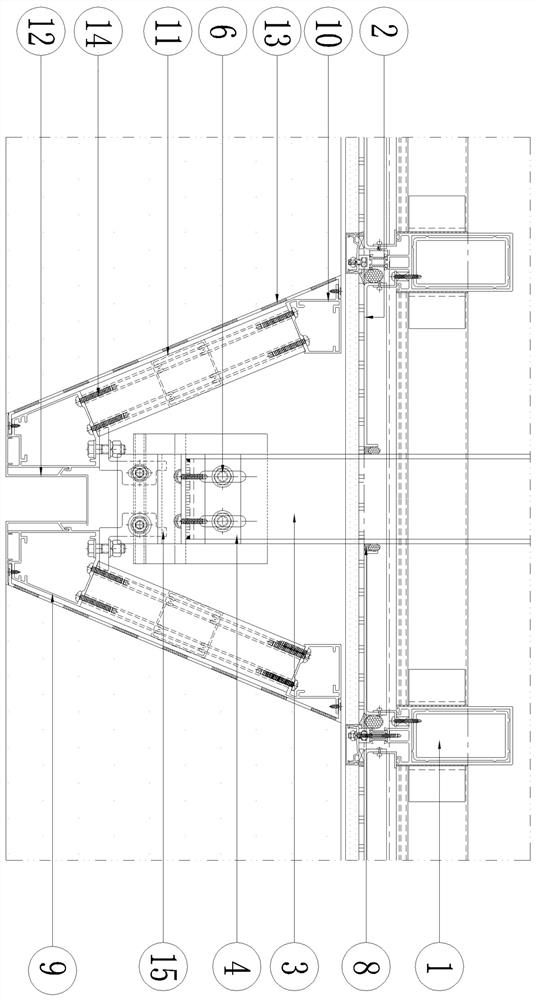

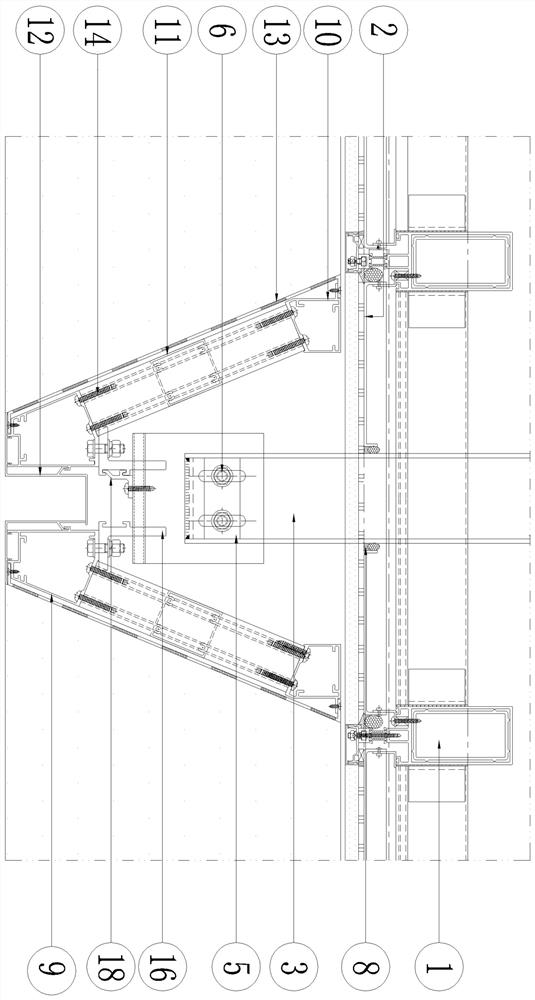

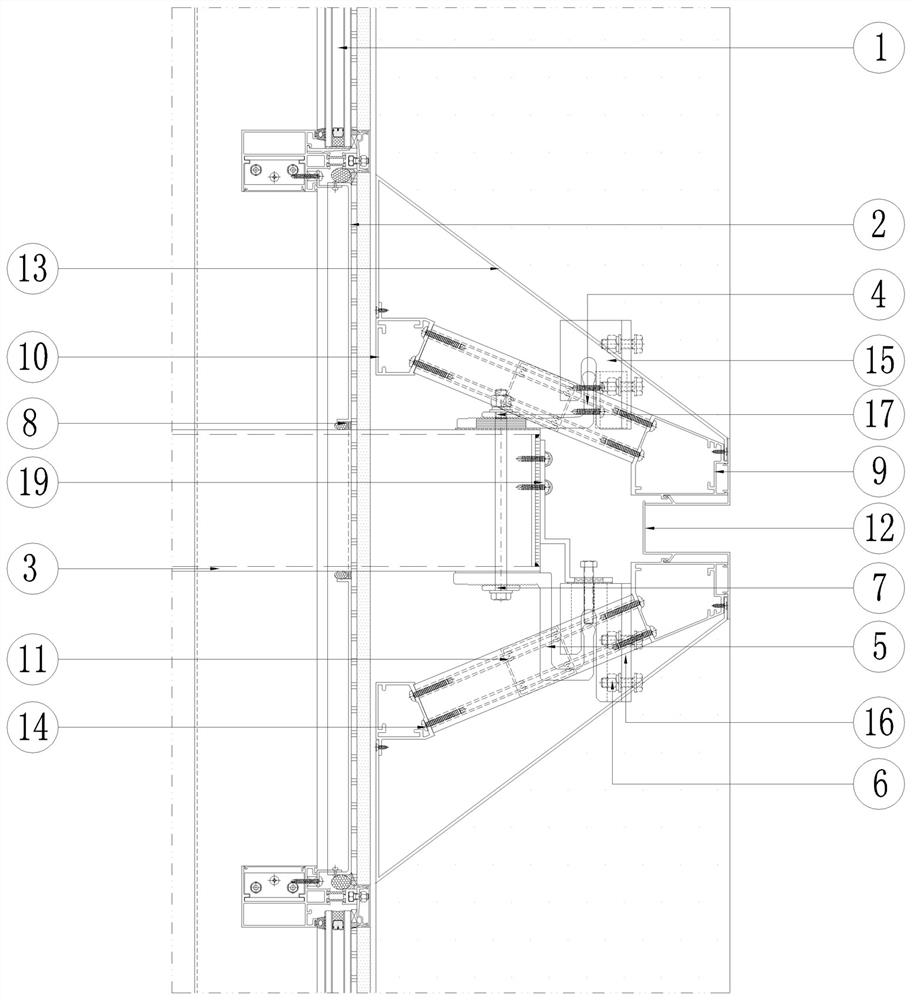

[0030] exist figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Among them, after the installation of the plane curtain wall 1 is completed, the root of the square steel pipe 3 is first connected to the structural beam. Sealant 8 seals, the top of the overhanging end of the square steel pipe 3 penetrates the tooth gasket 7 through the stainless steel bolt 6 to connect the upper hanging seat 4, and the underside of the overhanging end of the square steel pipe 3 penetrates the tooth gasket 7 through the stainless steel bolt 6 to connect the lower hanging Seat 5, hanging seat 4, the contact surface of hanging seat 5 and tooth gasket 7 have toothed structure, and have the oblong hole of in-and-out direction.

[0031] When the inner concave metal plate unit assembly is assembled in the factory, four aluminum outer frame profiles 9 are formed into a rectangular outer frame, four aluminum inner frame profiles 10 are formed into a rectangular inner frame, and the aluminum hor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com