Integrated carbon fiber energy-saving frame production process

A production process and carbon fiber technology, which is applied in the field of integrated energy-saving vehicle frame production process, can solve the problems of low strength of component joints, difficult welding, and cumbersome process, so as to reduce production cost and labor intensity, and solve the problem of strength and weight. , the effect of simplifying the production steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

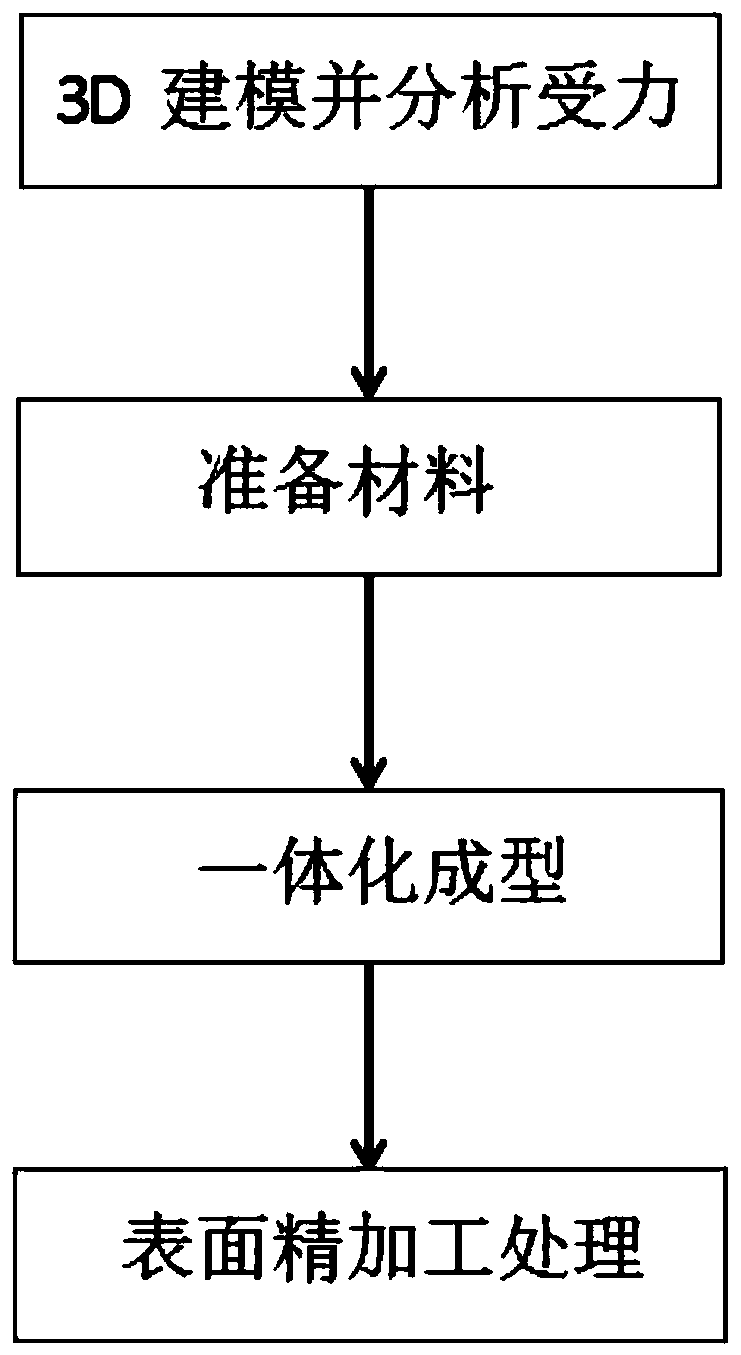

[0026] Such as figure 1 As shown, it is a flow chart of the manufacturing process of an integrated carbon fiber energy-saving frame provided by the present invention, including the following steps:

[0027] S1: 3D modeling: establish a 3D model according to the design requirements of the finished frame, mark the dimensions of each part of the frame, and conduct force analysis;

[0028] S2: Preparation of materials: According to the 3D model of the frame built in step S1, cut a square carbon fiber tube of the corresponding size (the specification is 20mm×20mm); use a 3D printer to print out the connections of the connection points according to the 3D model built in step S1 Structure; adjust the base glue and surface glue, and cut carbon fiber cloth (3k carbon fiber cloth, the cutting width is 5cm, and the length of a single piece is determined according to the actual situation);

[0029] S3: Integrated molding: Use 3D printed parts to make preliminary connections to the prepar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com