Permanent column formwork made of high toughness cementitious composite and manufacturing method thereof

A technology of composite materials and manufacturing methods, applied to columns, molds, pier columns, etc., can solve the problems of shortening the construction period and poor construction quality, and achieve the effects of shortening the construction period, simplifying the construction difficulty, and improving the construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

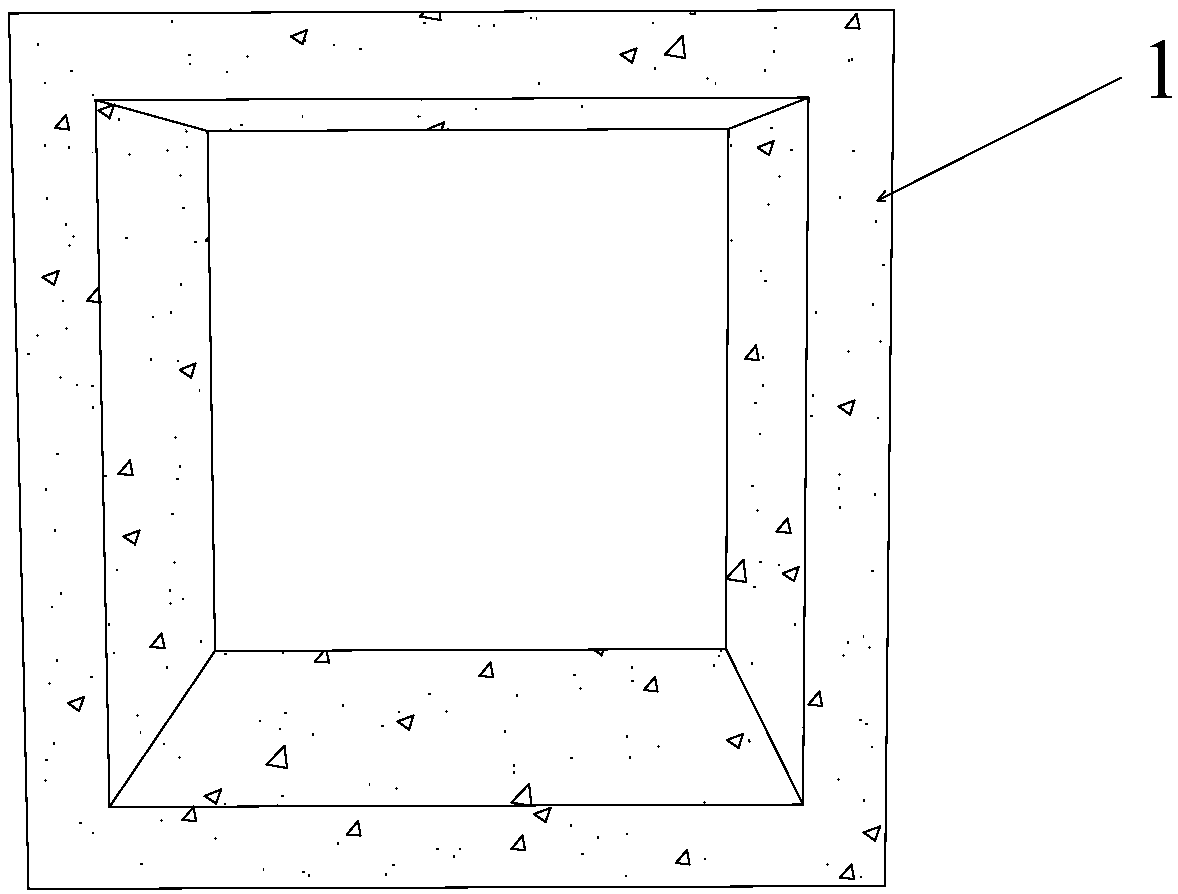

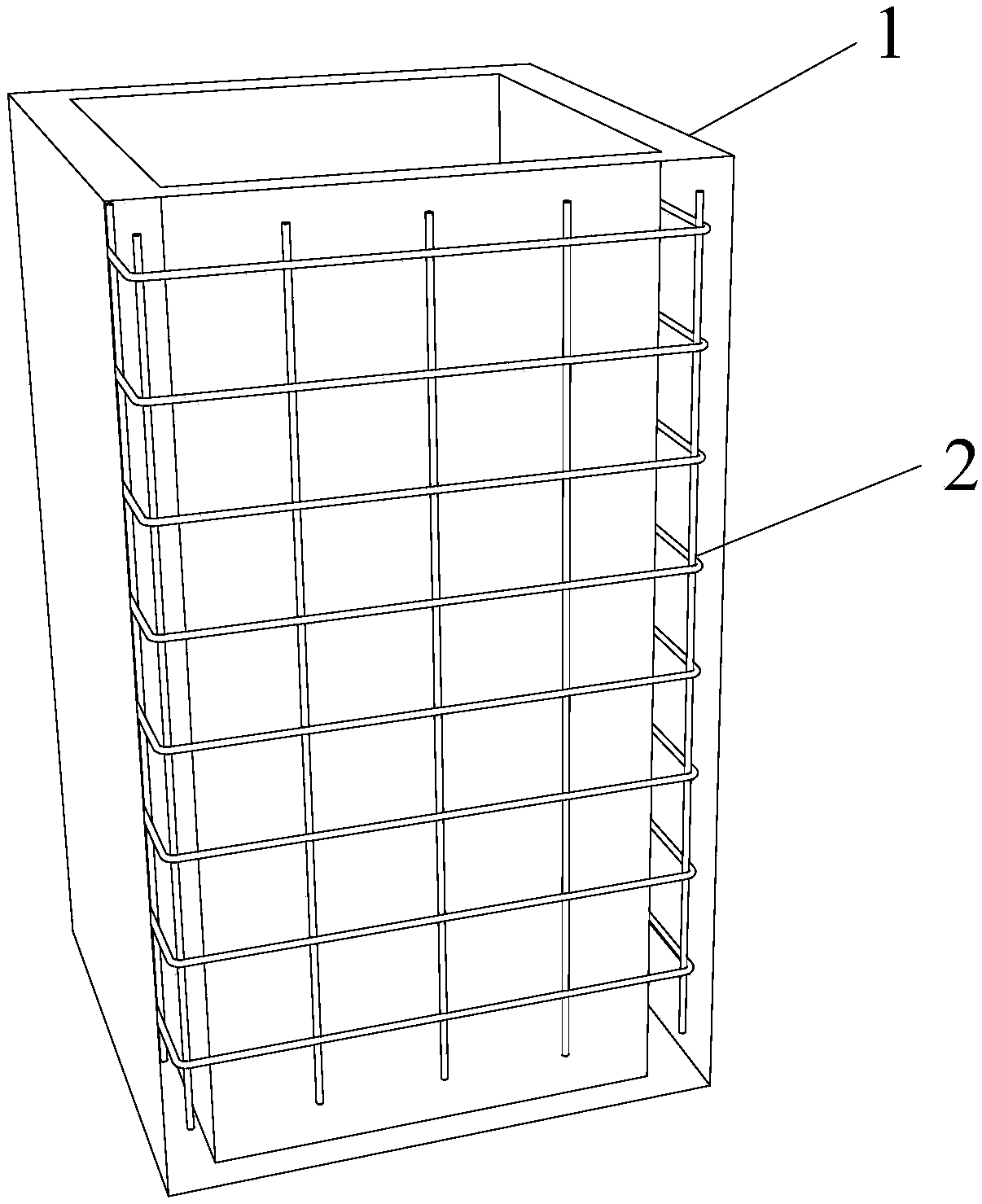

[0032] The structure of the permanent column formwork of high-toughness cement-based composite material of the present invention can be found in Figure 1 to Figure 2 As shown, it consists of a reinforced mesh 2 and a high-toughness cement-based composite material layer 1; It is formed by pouring in the high-toughness cement-based composite material layer 1, extends along the circumferential direction of the hollow column formwork, and is connected in a ring; the high-toughness cement-based composite material in the material layer is composed of fine sand, cement, fly ash After mixing with silica fume through additives, fiber materials are added.

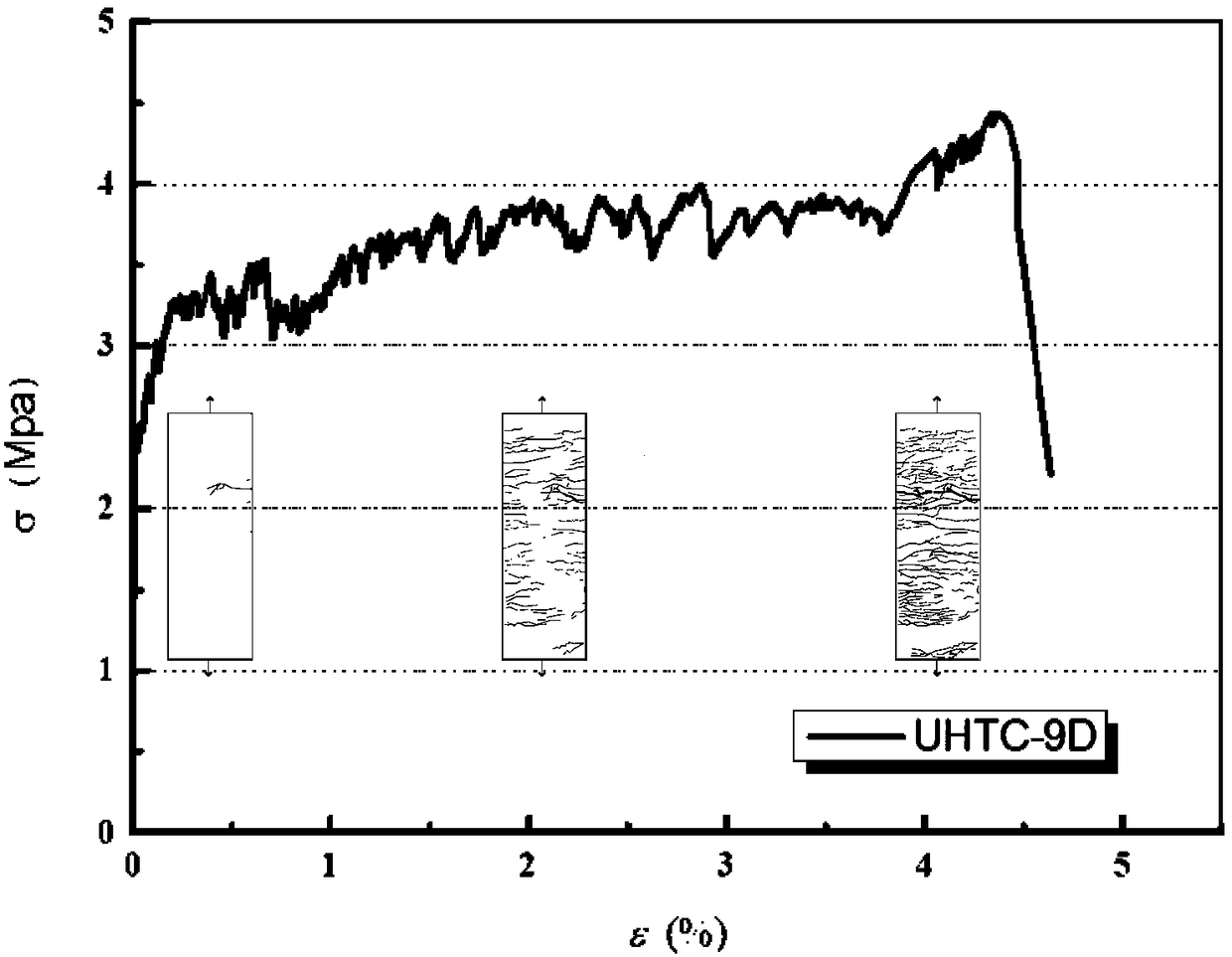

[0033] The high-toughness cement-based composite material is composed of cement, fly ash, silica fume and silica sand in a ratio of 15%:50%:5%:30% through additives to form a cement-based composite material, and the cement-based composite material cement A fiber material with a volume content of 1%-2.5% is mixed into the matrix com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com