Acidic gray dye mixture

A dye mixture, gray technology, used in organic dyes, dyeing methods, textiles and papermaking, etc., can solve the problems of easy dyeing or printing color spots, poor dyeing levelness, easy to appear color spots, etc., to improve solubility, The effect of improving dyeing performance and wide practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1. Preparation of dye mixture:

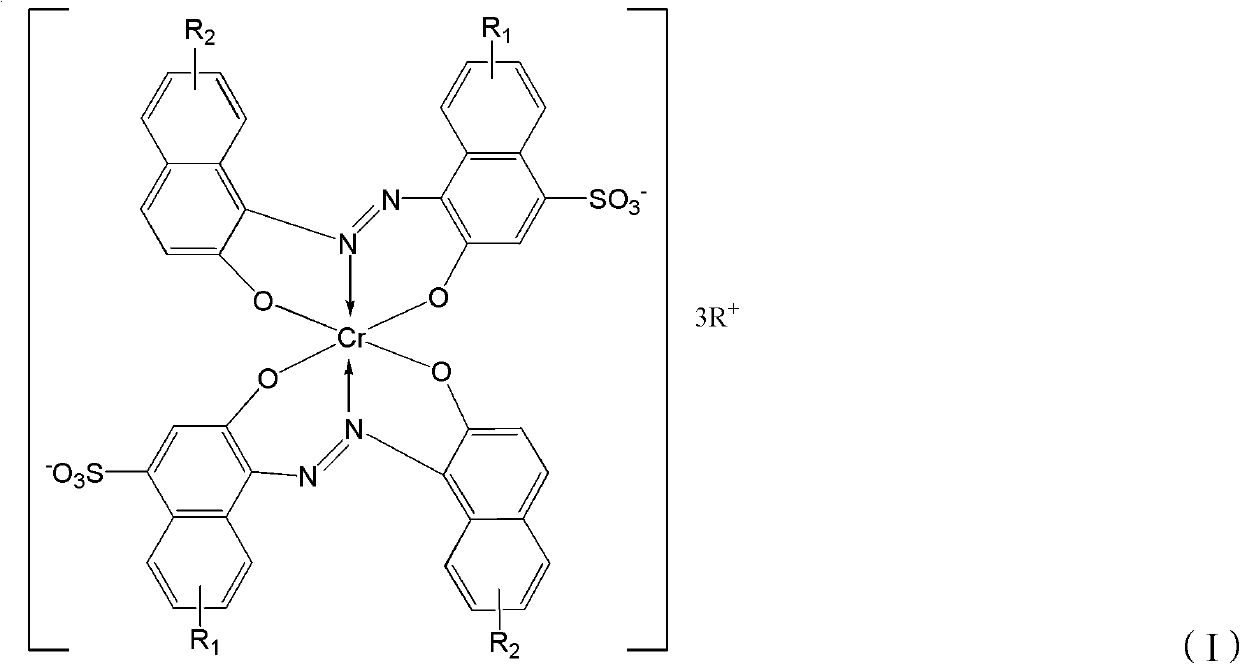

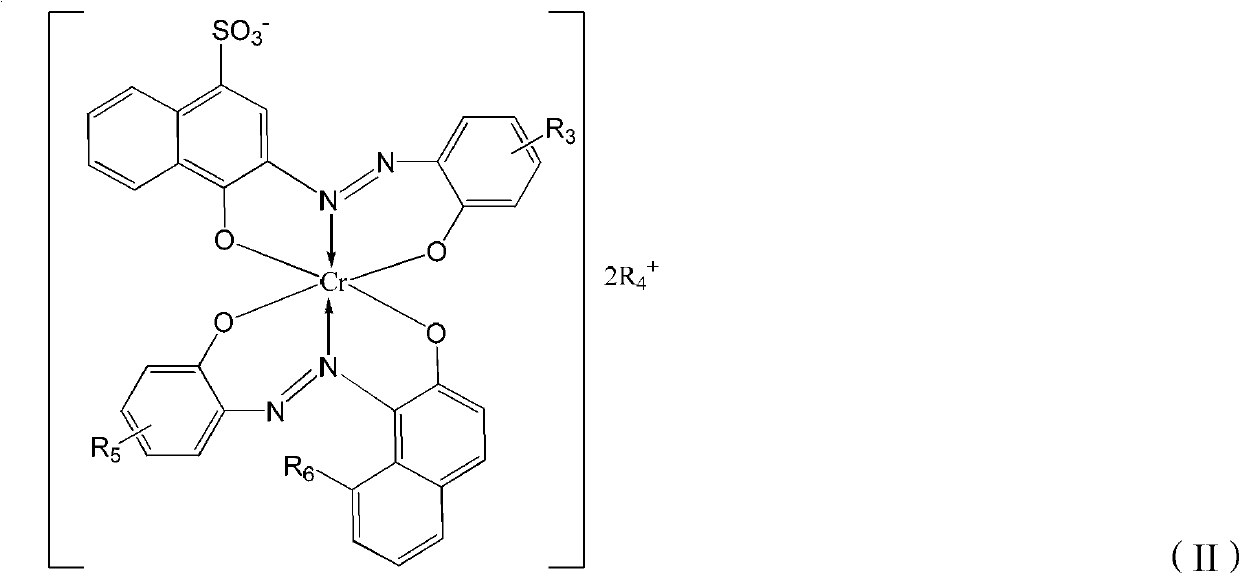

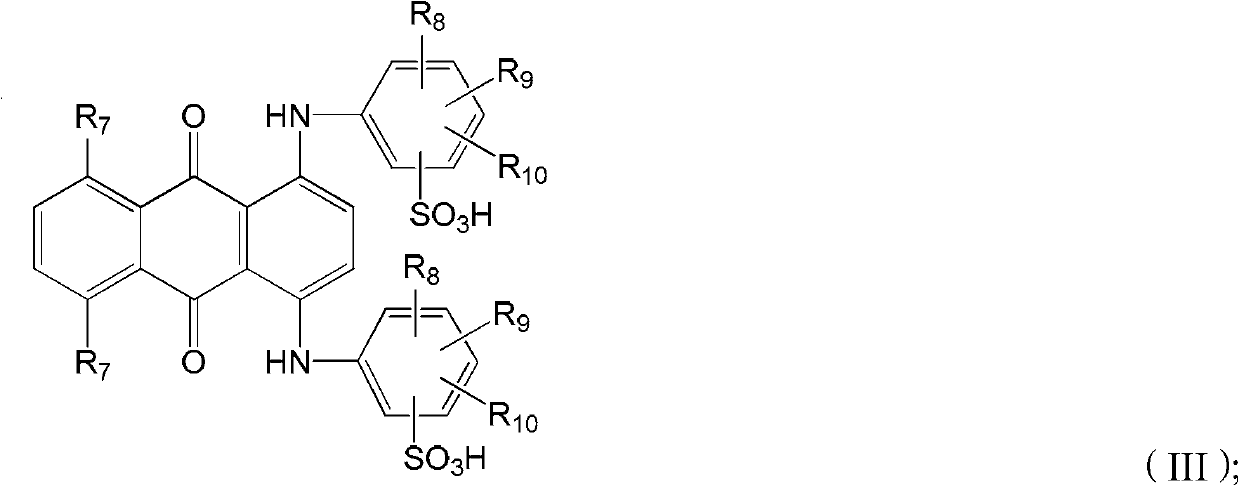

[0051] According to the raw material proportioning of Table 1, the metal complex dye C.I. acid black 172 of formula (I-1), the metal complex dye C.I. acid blue 193 of formula (I-2), the metal complex dye of formula (II-1) Combine dyestuff C.I. acid blue 317 and the anthraquinone type dyestuff C.I. acid green 27 of formula (III-4). Mix color, check dye shade, add 28.2% water-soluble starch and 20ml acetone, adjust the pH value to 7, adjust the dye strength to 150 and the solid content of the mixture to 93%, mix the mixture evenly, and wait for the process parameters of the spray drying tower Stable, the feed to the drying tower is dry, and the output is the finished dye. The finished dyed nylon fabric is gray in color.

[0052] Table 1

[0053]

[0054] Note: The content of dye components and water-soluble starch is the mass percentage of the dry product of each component based on the total amount of the dye mixture.

[0055] 2. Pe...

Embodiment 2

[0062] 1. Preparation of dye mixture:

[0063] According to the raw material ratio of Table 3, the metal complex dye C.I. acid black 172 of formula (I-1), the metal complex dye C.I. acid blue 193 of formula (I-2), the metal complex dye of formula (II-1) Combined dyestuff C.I. acid blue 317 and the former dyestuff filter cake conversion dry product quality of the anthraquinone type dyestuff C.I. acid green 28 containing formula (III-5) with the ratio of 40%, 25%, 7% and 8% and the water of 200g Beat the color, check the color of the dye, add 20% of water-soluble starch and sodium sulfate and 20ml of acetone, adjust the pH to 8, adjust the dye strength to 150 and the solid content of the mixture to 93%, mix the mixture evenly, wait The process parameters of the spray drying tower are stable, the feed to the drying tower is dry, and the output is finished dyes. The finished dyed nylon fabric is gray in color.

[0064] table 3

[0065]

[0066] Note: The content of dye compo...

Embodiment 3

[0075] 1. Preparation of dye mixture:

[0076] According to the raw material ratio of Table 5, the metal complex dye C.I. acid black 194 of formula (I-1), the metal complex dye C.I. acid blue 193 of formula (I-2), the metal complex dye of formula (II-1) Combined dyestuff C.I. acid blue 317 and the former dyestuff filter cake conversion dry product quality of the anthraquinone type dyestuff C.I. acid green 27 containing formula (III-4) with the ratio of 38%, 22%, 5% and 12% and the water of 200g Beat the color, check the color of the dye, add 23% of sodium sulfate, adjust the pH to 8, adjust the strength of the dye to 150 and the solid content of the mixture to 92%, mix the material evenly, wait for the process parameters of the spray drying tower to be stable, and dry The tower feed material is dried, and the output material is finished dye, and the color of the finished dye dyed nylon fabric is gray.

[0077] table 5

[0078]

[0079] Note: The content of dye components ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com