Multi-color polyester slub fully drawn yarns (FDYs) produced by heat roller at variable speed and production method thereof

A technology of full-drawn yarn and production method, which is applied in stretch spinning, filament/thread forming, textiles and papermaking, etc. It can solve the problems of lack of wearing comfort, poor air permeability and low differentiation of polyester fabrics, and achieve Significant economic and social benefits, simple equipment modification, good waterproof and breathable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

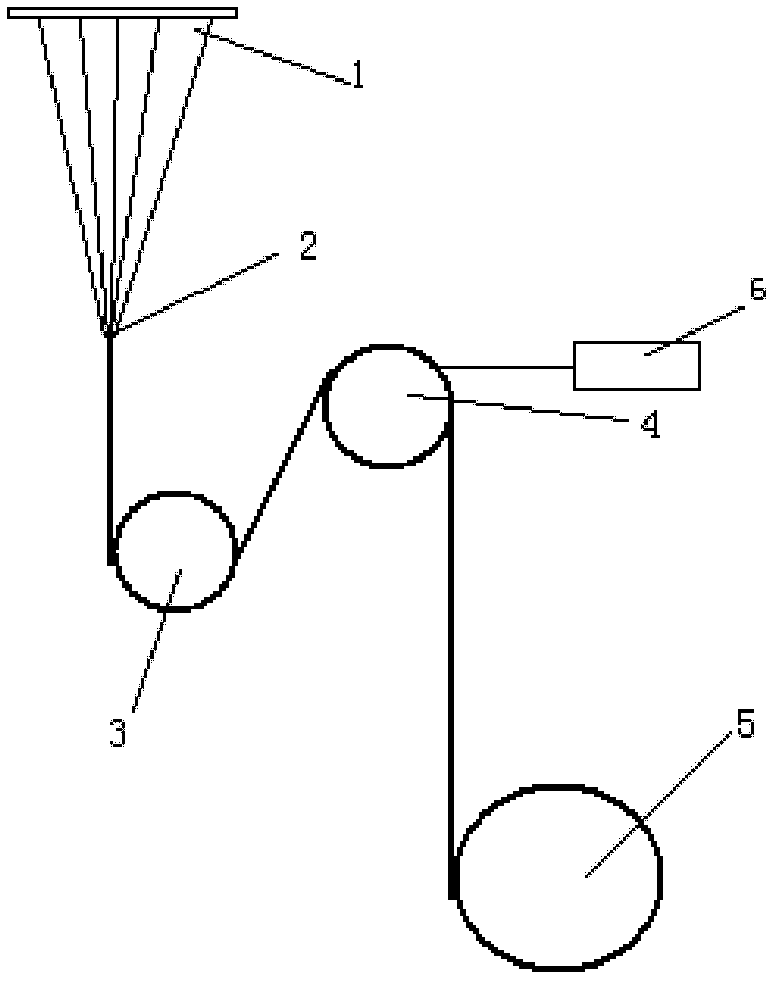

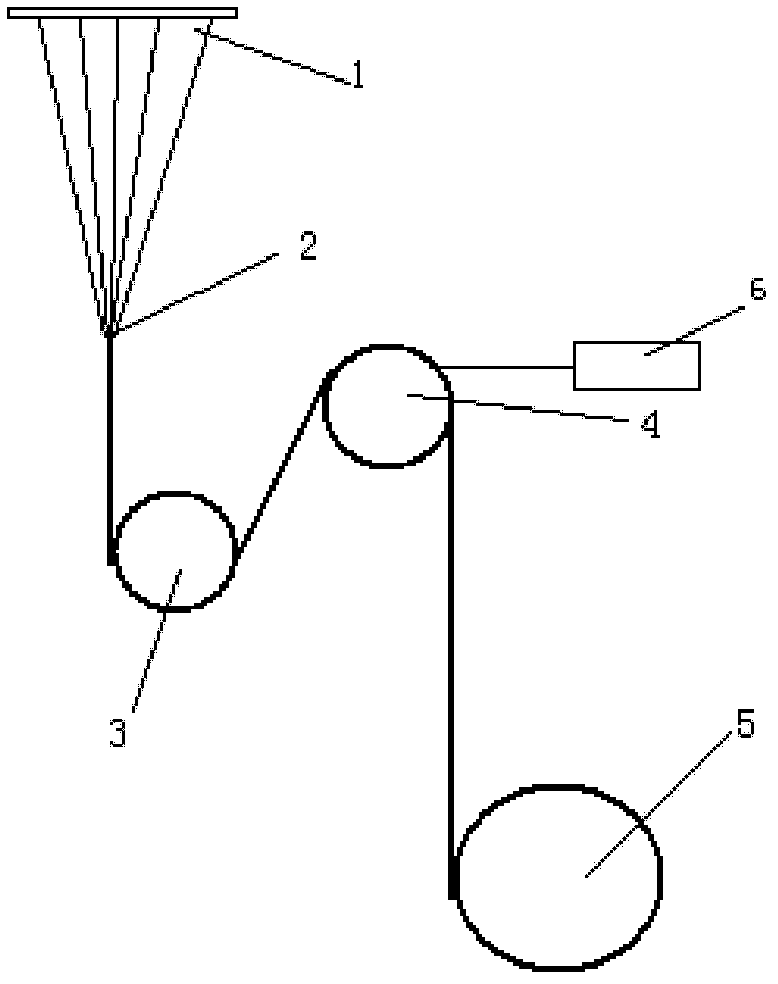

[0023] Manufacture of polyester multi-color slub full-drawn yarn FDY produced by heat roller variable speed:

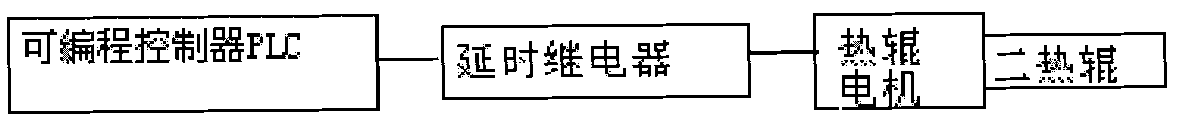

[0024] Change the internal control constant speed working mode of the frequency converter that controls the motor of the second heat roller (4), adopt the multi-stage speed change external control mode to work, and control the second heat roller (4) according to the setting by the connected programmable controller (6). The program operates at different speeds, so that the stretching ratio of the filament formed by the speed difference between the first hot roller (3) and the second hot roller (4) changes accordingly.

[0025] One hot roller V=1100m / min, two hot rollers with multi-stage speed: v1=1760m / min, drawing ratio DR1=1.6; v2=2750m / min, drawing ratio DR2=2.5; v3=3600m / min, drawing ratio DR3=3.2; corresponding stretching time: t1=1ms, t2=1ms, t3=1ms, and the acceleration time is 0.01 second. The obtained slub length is 6cm, the spacing is also 38cm, 53cm, 45cm, ...

Embodiment 2

[0027] Manufacture of polyester multi-color slub full-drawn yarn FDY produced by heat roller variable speed:

[0028] Change the internal control constant-speed working mode of the frequency converter that controls the motor of the second heat roller (4), adopt the multi-stage speed change external control mode to work, and control the second heat roller (4) according to the setting by the connected programmable controller (6). The program operates at different speeds, so that the stretching ratio of the filament formed by the speed difference between the first hot roller (3) and the second hot roller (4) changes accordingly.

[0029] One hot roller V=1800m / min, two hot rollers with multi-stage speed: v1=4200m / min, drawing ratio DR1=2.3; v2=2350m / min, drawing ratio DR2=1.79; v3=2350m / min, drawing ratio DR3=1.79; corresponding stretching time: t1=10ms, t2=5ms, t3=4ms, and the acceleration time is 0.05 seconds. The obtained slub lengths are 70cm, 20cm, 20cm, the spacing is also...

Embodiment 3

[0031] Manufacture of polyester multi-color slub full-drawn yarn FDY produced by heat roller variable speed:

[0032] Change the internal control constant-speed working mode of the frequency converter that controls the motor of the second heat roller (4), adopt the multi-stage speed change external control mode to work, and control the second heat roller (4) according to the setting by the connected programmable controller (6). The program operates at different speeds, so that the stretching ratio of the filament formed by the speed difference between the first hot roller (3) and the second hot roller (4) changes accordingly.

[0033] One hot roller V=1500m / min, two hot rollers with multi-stage speed: v1=3900m / min, draw ratio DR1=2.6; v2=1770m / min, draw ratio DR2=2.2; v3=1950m / min, draw ratio DR3=2.0; corresponding stretching time: t1=3ms, t2=7ms, t3=4ms, t4=6ms, and the acceleration time is 0.03 seconds. The obtained slub length is 20cm, 21cm, 20cm, the spacing is 273cm, 196...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com