Modular glass steel pipeline and method for repairing underground broken pipeline by using same

A fiberglass, modular technology, applied in the direction of pipes/pipe joints/fittings, pipes, rigid pipes, etc., can solve problems such as water supply and drainage pipeline damage, underground pipeline repair and transportation difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

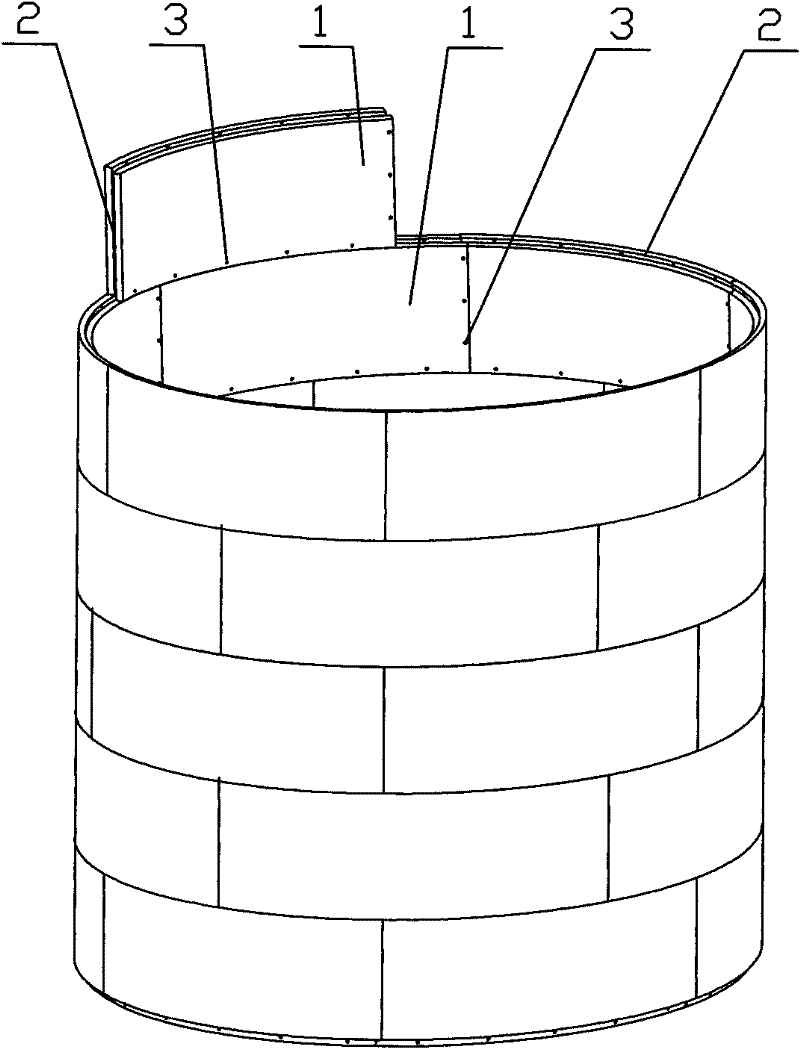

[0023] figure 1 It is a schematic diagram of the structure of the modular FRP pipeline. It can be seen from the figure that it is a circular pipe, and the circular pipe is composed of pieces of arc-shaped sheet modules 1 spliced with each other in the circumferential direction and the axial direction respectively.

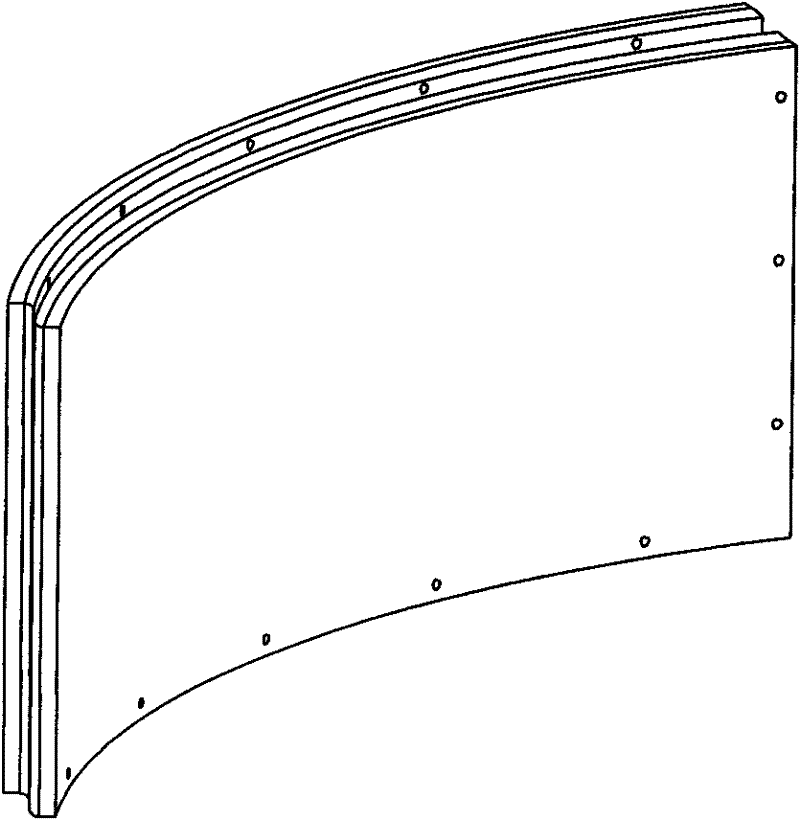

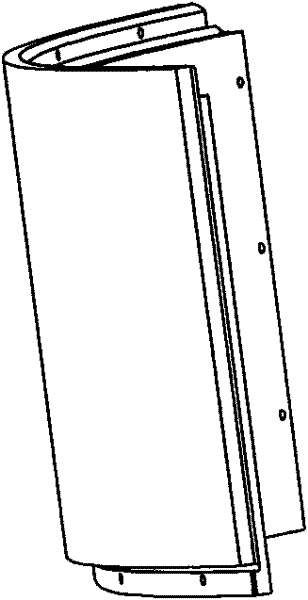

[0024] The arc-shaped sheet module 1 is a quadrilateral such as Figure 1 to Figure 6 As shown, the opposite sides of one pair of arcs have the same curvature as the circular pipe, and the other pair of opposite sides are straight lines. Described sheet-like module is shaped on the lap edge 2 that is spliced with each other all around, forms the form splicing of lap joint between adjacent sheet-like module 1 such as Figure 7 shown. The lap 2 is the lap 2 on the outer surface of the pipe enclosing the inner surface of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com