Method and device for manufacturing solar cell electrode

A technology of solar cells and solar cells, applied in circuits, electrical components, manufacturing tools, etc., can solve the problems of large shading area and high resistance of grid lines, and achieve the effects of reducing series resistance and improving photoelectric conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

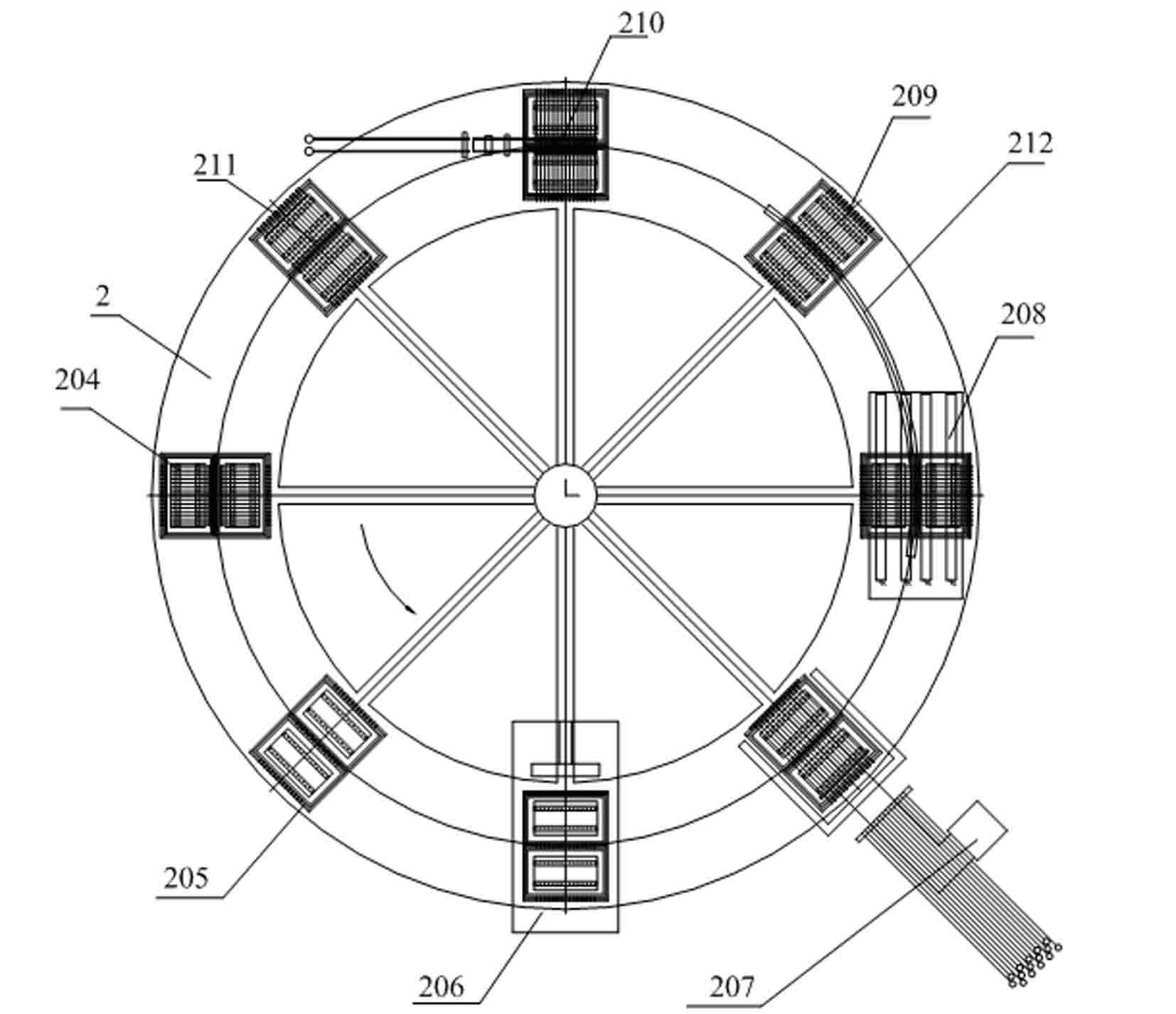

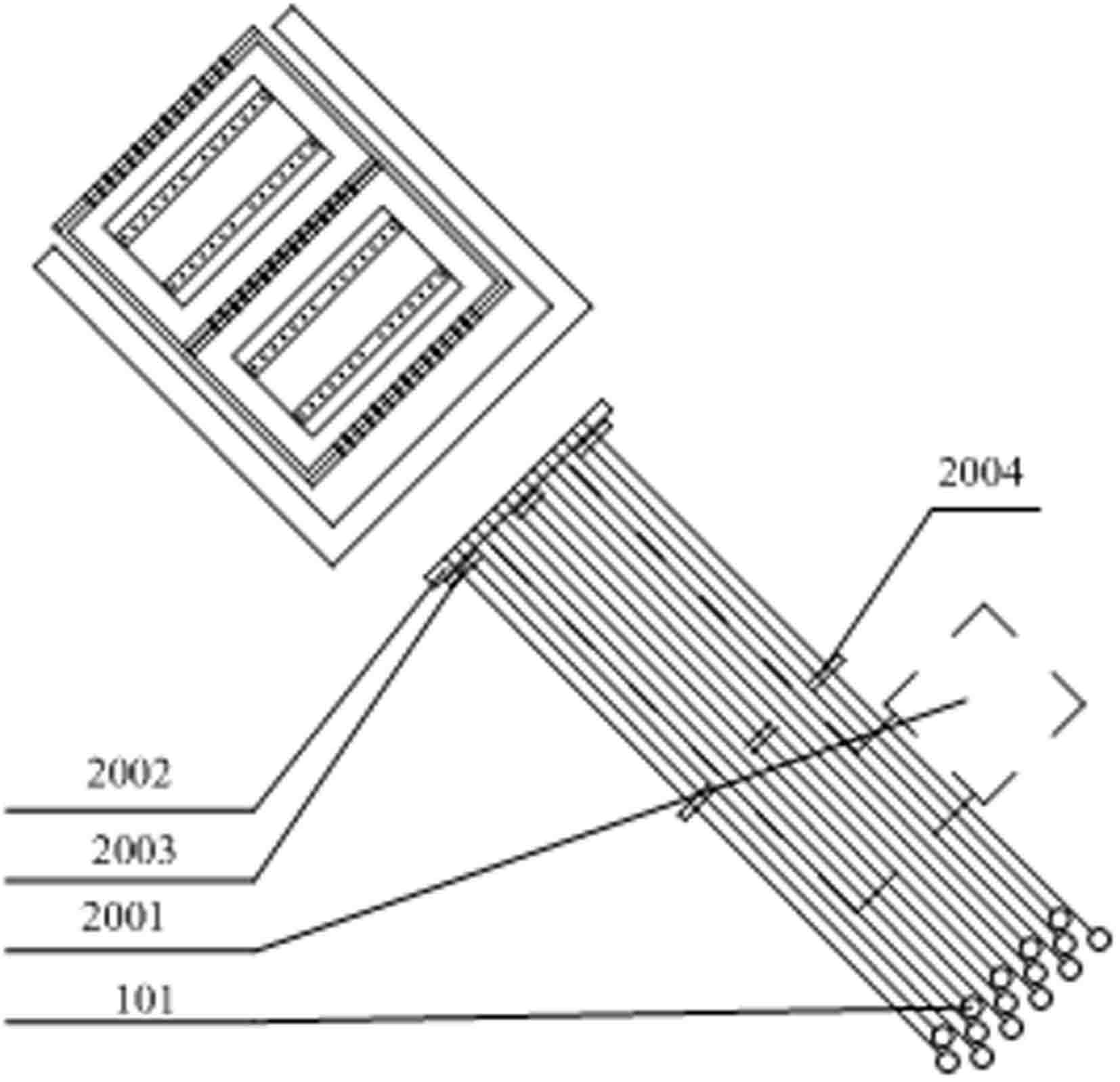

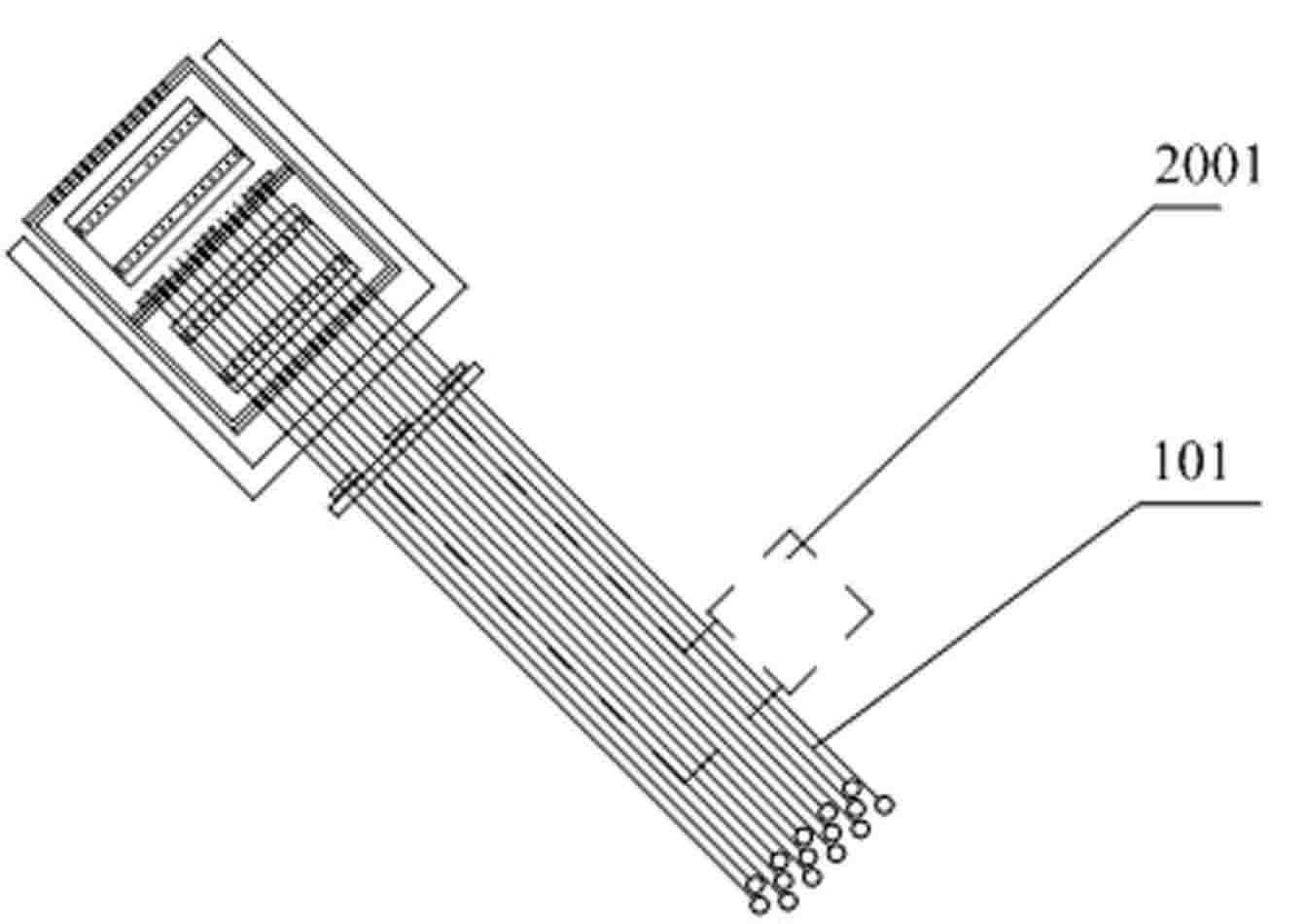

[0036] Such as figure 1 and figure 2 As shown, a device for making solar cell electrodes, it includes a visual alignment manipulator and a rotary positioning device 2, and the rotary positioning device 2 includes a tray 204, an online printing device 206, a wiring device 207, an infrared welding device 208, and a cooling device 209. The bus ribbon welding device 210 and the wire cutting device 211, the visual alignment manipulator is used to place the basic solar cell 104 on the tray 204 of the rotary positioning device 2 or remove the basic solar cell 104 from the tray 204, so The rotary positioning device 2 is used to sequentially send the basic solar cells 104 on the tray 204 to the online printing device 206, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com