Capacitance compensation fling-cut switch

A switching switch and capacitance compensation technology, which is applied in reactive power compensation, reactive power adjustment/elimination/compensation, cooling/ventilation/heating transformation, etc., can solve the problems of easy short circuit, trouble, high temperature, etc. between wires and secondary lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

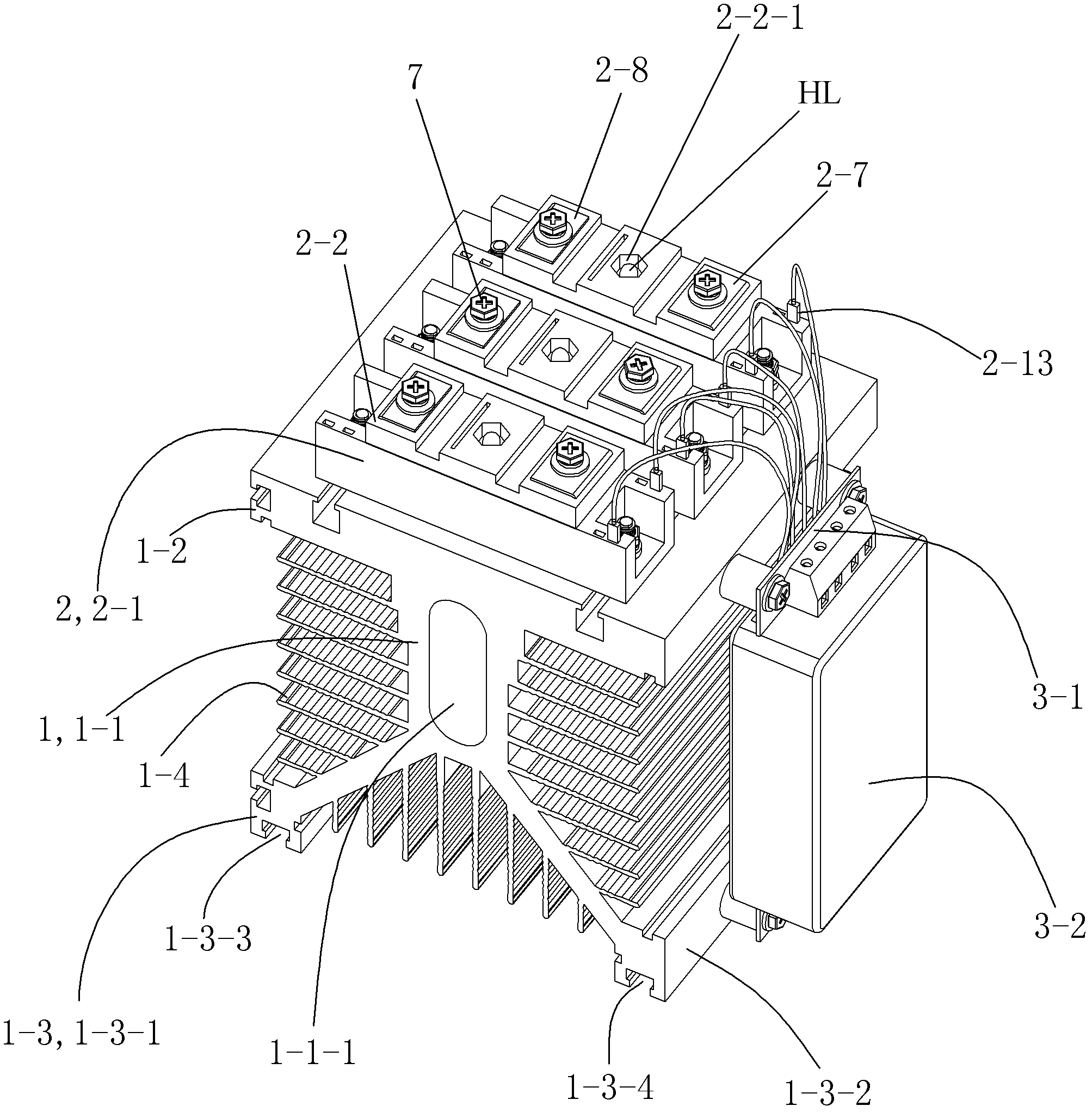

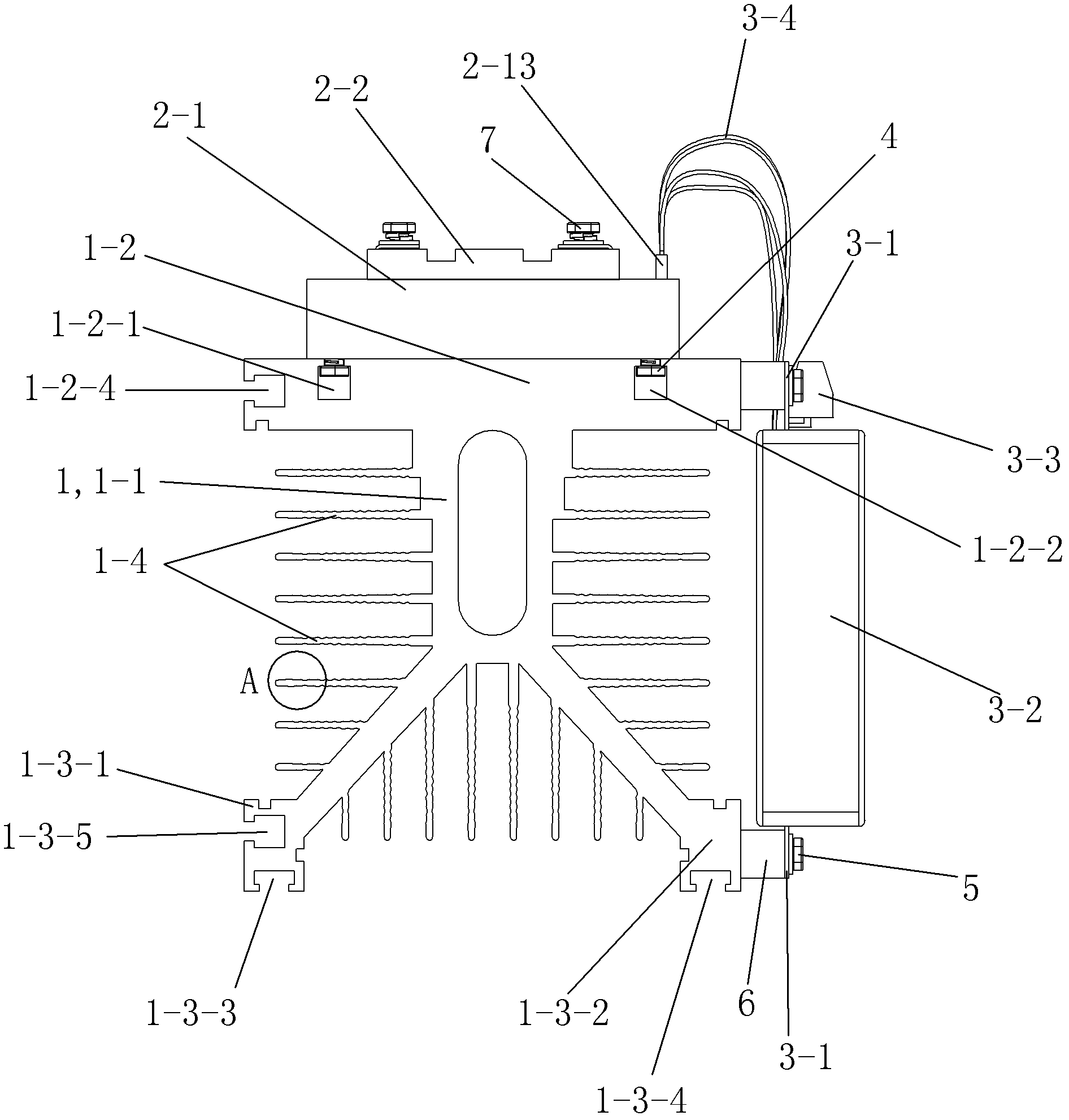

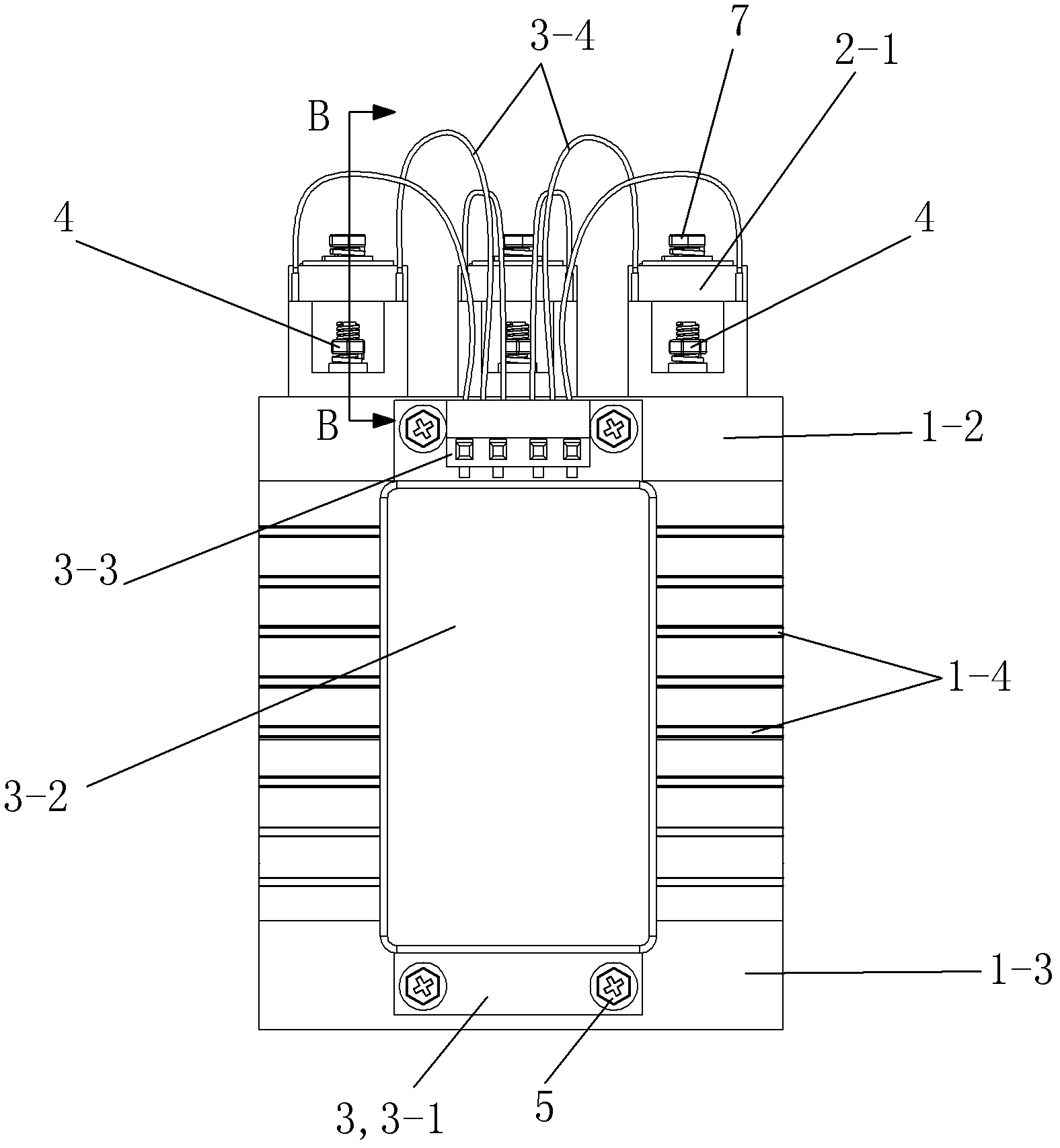

[0044] See figure 1 and figure 2 , the capacitance compensation switching switch of this embodiment (hereinafter referred to as the switching switch) includes a heat dissipation base 1 , a thyristor module 2 and a DC power supply device 3 .

[0045] See Figure 6 , the heat dissipation base 1 is made of an aluminum alloy profile after cutting and drilling. The aluminum alloy profile is obtained by extruding the aluminum alloy bar with the grade of 6063 through a mold of a corresponding shape at a certain temperature. The heat dissipation base 1 includes a heat dissipation support part 1-1, a mounting plate part 1-2, a mounting foot part 1-3 and a heat dissipation fin 1-4. The cross-section of the heat dissipation support part 1-1 is basically rectangular, with a waist-circular heat dissipation hole 1-1-1 in the middle; the installation platen part 1-2 is located above the heat dissipation support part 1-1 and arranged horizontally; the installation The upper side of the p...

Embodiment 2)

[0061] See Figure 11, the rest of this embodiment is the same as that of Embodiment 1, the difference is that: the right side of the mounting plate portion 1-2 of the heat dissipation base 1 is provided with an upper right T-shaped slot 1-2 that opens to the right and is arranged along the front and rear direction -5, and the two platen mounting screw holes 1-2-3 are also removed accordingly. The bottom of the right mounting foot 1-3-2 is also provided with the lower right T-slot 1-3-6 that is positioned at the opening above the lower right T-slot 1-3-4 to the right along the front-to-back direction, and the two installation Screw holes 1-3-7 are also correspondingly removed. The circuit board 3-1 is fixedly connected to the heat dissipation base 1 through the fasteners 4 arranged in the upper right T-shaped slot 1-2-5 and the lower right T-shaped slot 1-3-6.

Embodiment 3)

[0063] The rest of this embodiment is the same as Embodiment 1, the difference is that: the power input junction block 3-3 of the DC power supply device 3 is a two-position power input junction block, and the DC power output leads 3-4 are corresponding 3 groups of 6 root. This switching switch can be used as a three-phase co-compensation capacitor compensation switching switch. When in use, connect one phase of the three-phase AC power supply to the copper first connecting piece 2-7 of each thyristor module 2, so that the copper second connecting piece 2-8 is connected to the corresponding capacitor in an angle connection (△) The corresponding one of the joints of the group is connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com