Automatic geared variator for changing gear ratio without disengaging gears and without control devices or therewith

A technology of automatic transmission and gear transmission, which is applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc. It can solve the problem that the gear transmission ratio cannot be changed automatically without control equipment without separating the gears, and achieves low material consumption, Effects of reducing fuel consumption and exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

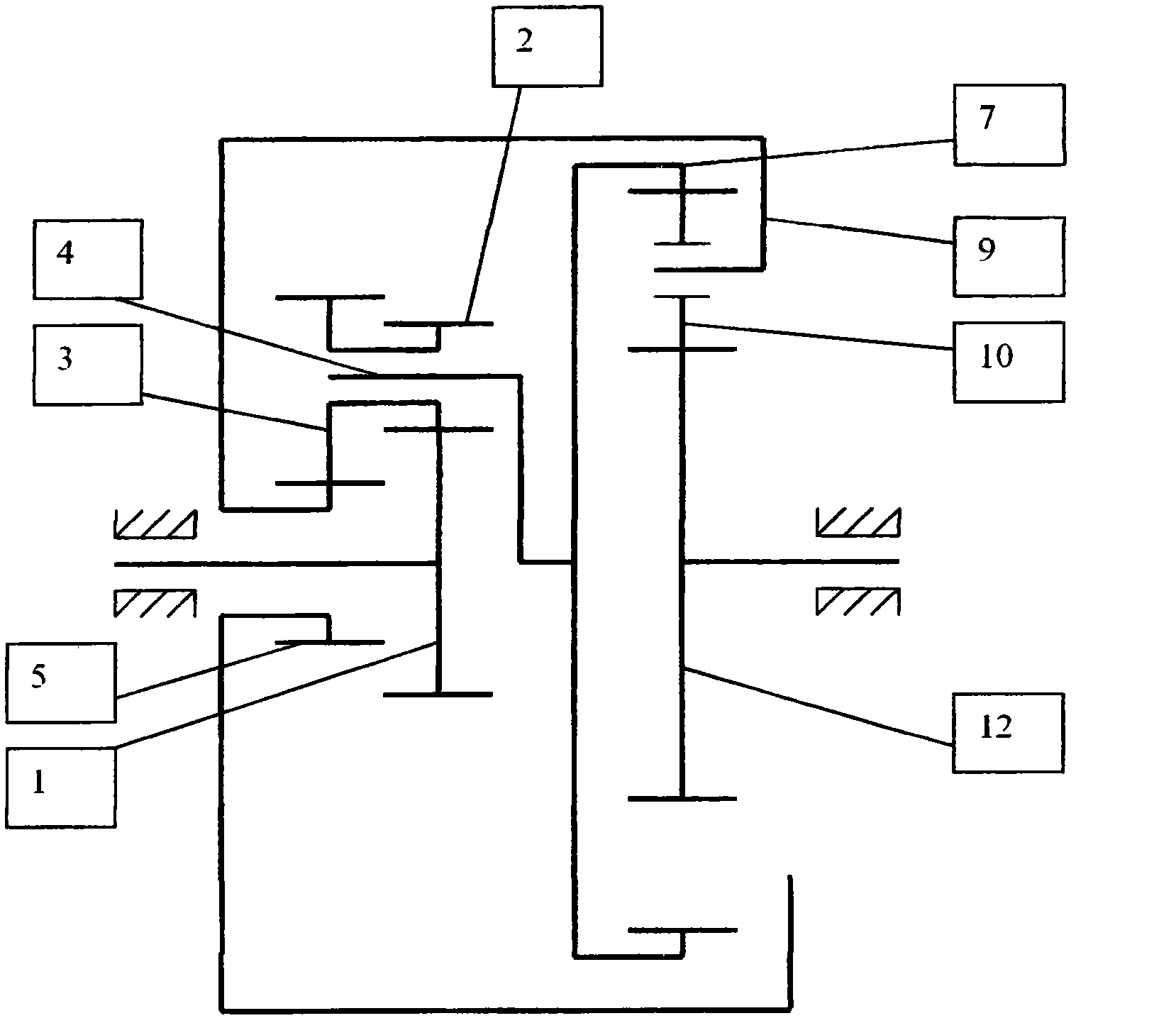

[0047] The sun gear 1 of the first stage can be used as a driving gear, while the sun gear 12 of the second stage can be used as a driven gear, or vice versa. The kinematic chain may be configured to integrate with another kinematic chain by mating any suitable gears.

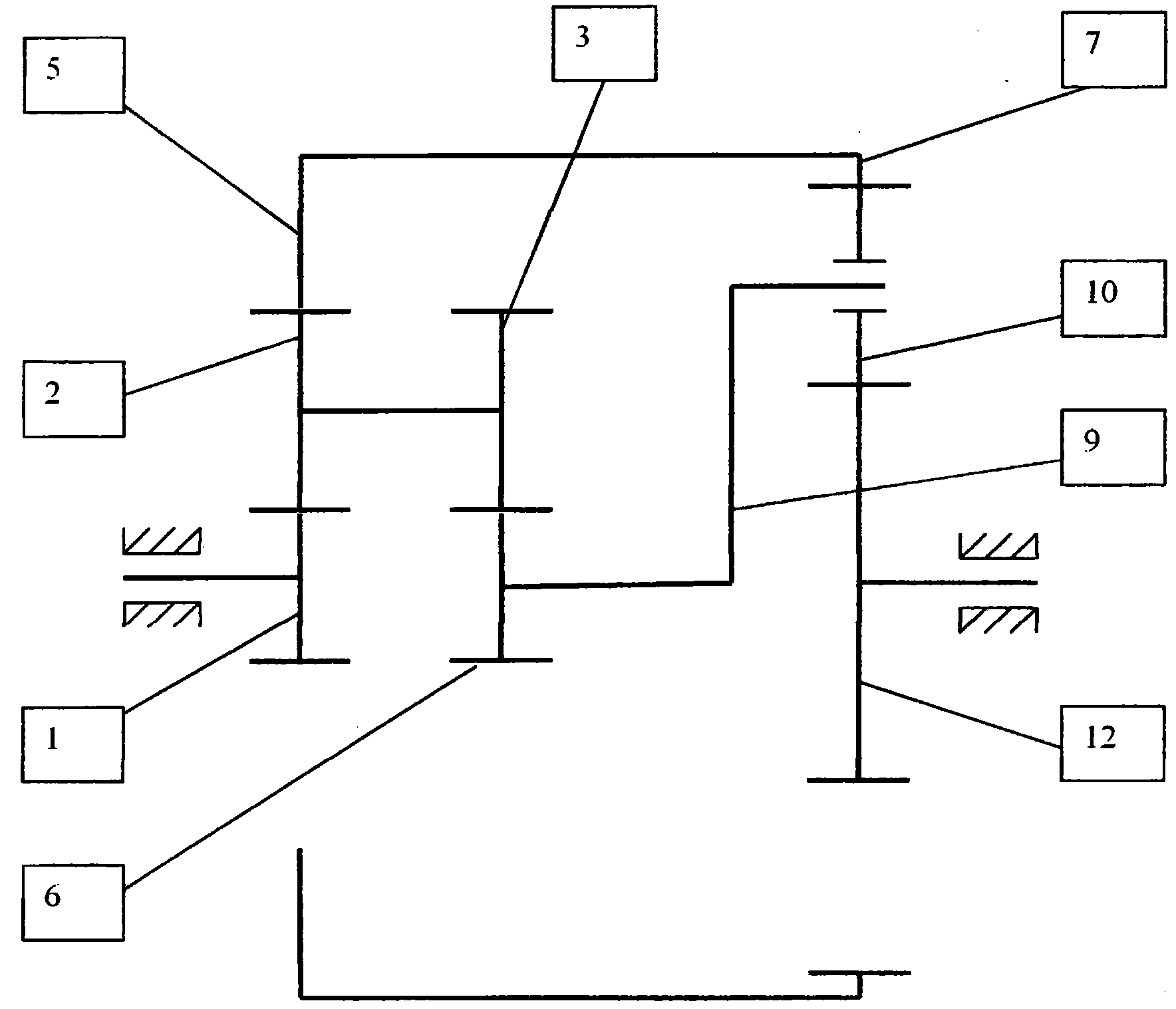

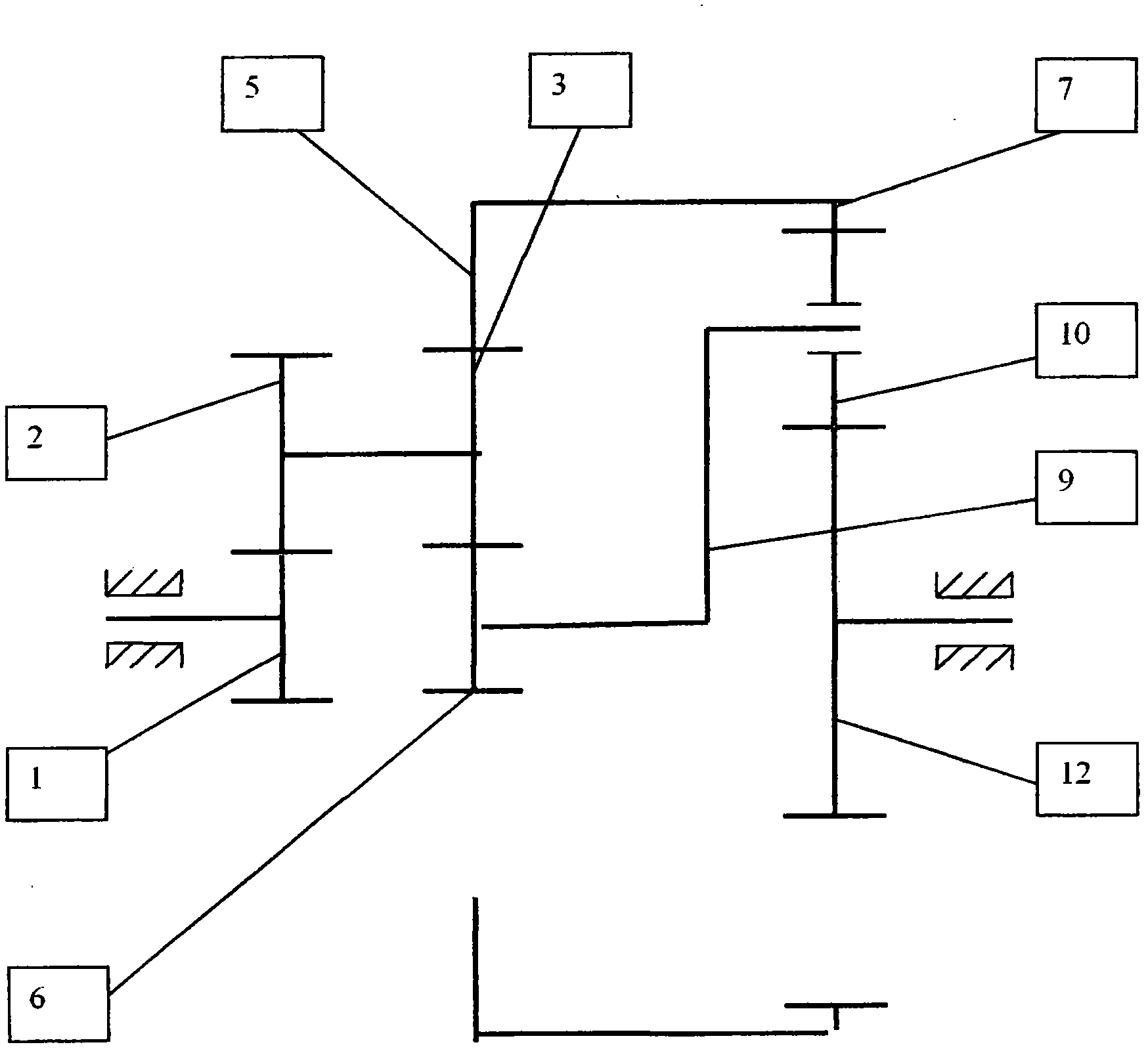

[0048] The geared automatic transmission provides at least two power transfer streams. Such as figure 1 As shown in , a power transmission flow is external, from the sun gear 1, through the first planet gear 2 of the first stage, then through the sun gear 5 of the first stage and the sun gear 7 of the second stage (where the sun gear 5 and 7 are integral with each other), then the power transmission flow passes through the planetary gear 10 of the second stage, and finally to the sun gear 12, which is a driven gear;

[0049] The other power transmission flow is internal, from the sun gear 1, through the first planetary gear 2 of the first stage and the planetary gear 3 of the first stage (gear 3 is integral ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com