Three-roller multi-wire cutting machine

A multi-wire cutting machine and cutting roller technology, which is applied to fine working devices, stone processing equipment, manufacturing tools, etc., can solve problems such as bending and unstable cutting wire tension, and achieve high efficiency, stable cutting quality, and equipment volume small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

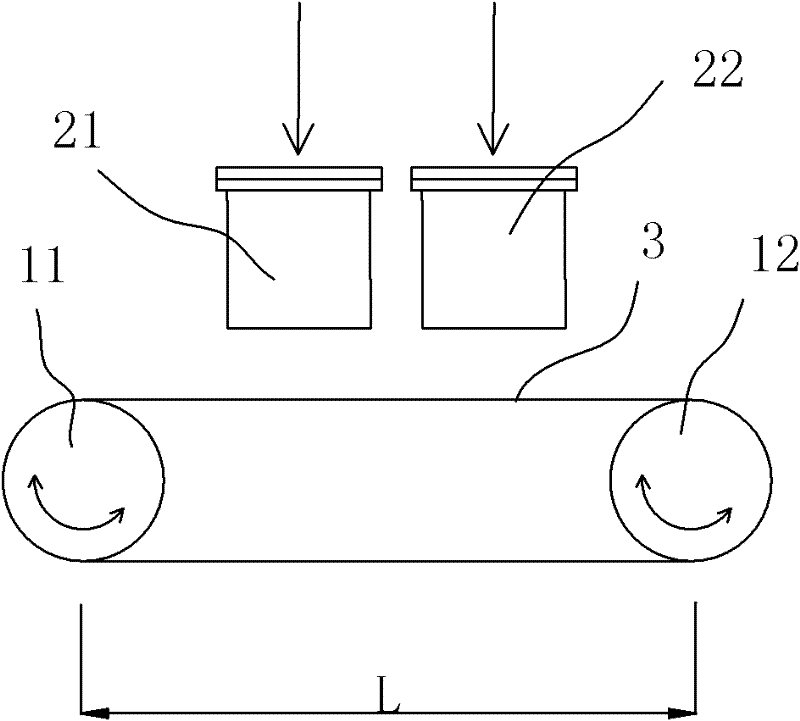

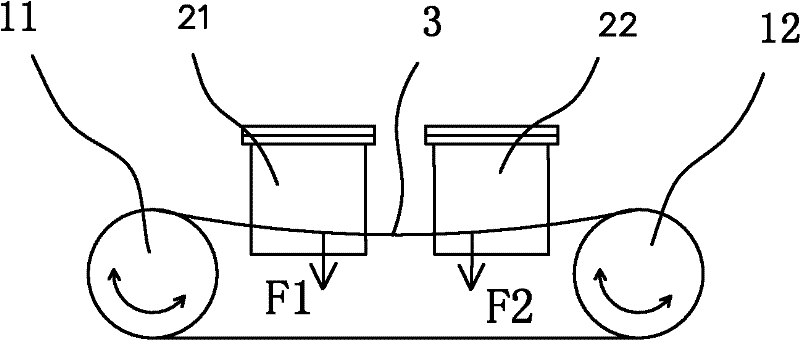

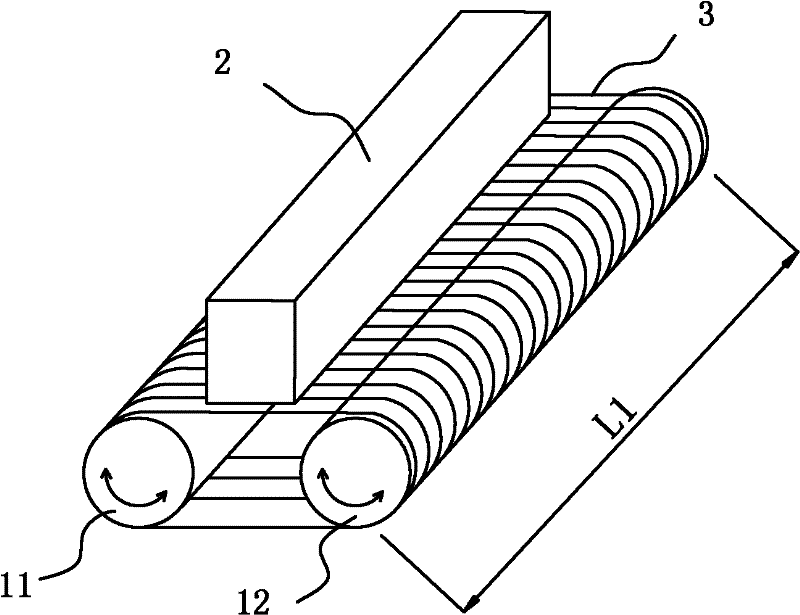

[0013] Such as Figure 4 , Figure 5 As shown, two cutting rollers 11, 12 and auxiliary cutting roller 13 are erected in parallel in the cutting chamber 71 respectively, and the surfaces of two cutting rollers 11, 12 and auxiliary cutting roller 13 are provided with wire grooves ( Figure 4 and 5 not shown), the auxiliary cutting roller 13 is arranged on the center of symmetry or above the center of symmetry of the two cutting rollers 11, 12, and supports the cutting line 3 between the two cutting rollers 11, 12, so that the auxiliary cutting roller 13 Two independent cutting areas are formed between the two sides and the two cutting rollers 11, 12, and the angle α between the cutting lines 31, 32 on both sides of the auxiliary cutting roller 13 and the plane 14 where the axes of the two cutting rollers are located is 0 In the range of °~30°, the included angle α is preferably in the range of 0°~15°; above the two cutting rollers 11 and 12, there are two sets of symmetricall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com