Device for crushing steel slag and recovering heat

A heat recovery device and a technology for steel slag, applied in the direction of improving process efficiency, etc., can solve problems such as low heat storage performance, intermittent operation, and waste heat utilization rate of less than 40%.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

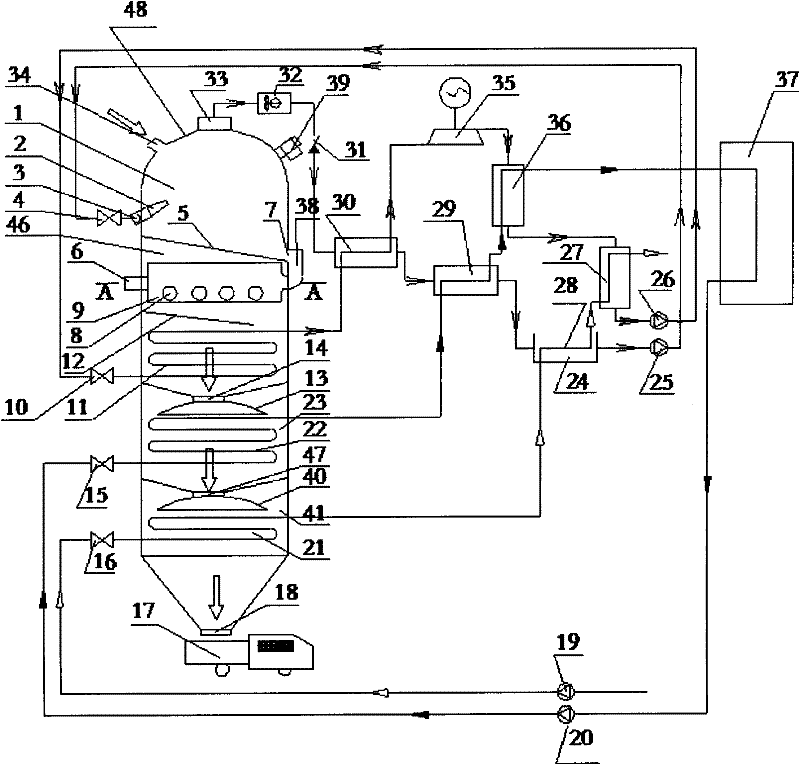

[0025] Below in conjunction with accompanying drawing, the present invention will be further described:

[0026] Such as figure 1 , a steel slag crushing and heat recovery device, characterized in that the device includes: an integrated tank 48, the top of the integrated tank 48 is provided with a feed port 34, an exhaust port 33, and the bottom of the integrated tank 48 is provided with a terminal slag outlet 18 ;

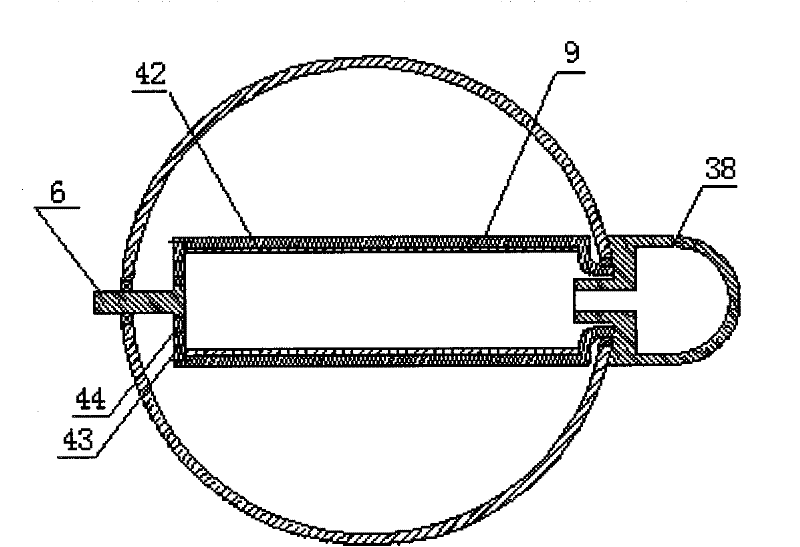

[0027] In the integrated tank 48, the upper part is divided into a spray chamber 1 by a slag collecting plate 5 arranged on an incline. The spray nozzle 2 is installed in the spray chamber 1. The lowest part of the slag collecting plate 5 is provided with a first-level slag outlet 7. The slag port 7 communicates with a slag collecting box 38 after passing through the integrated tank 48;

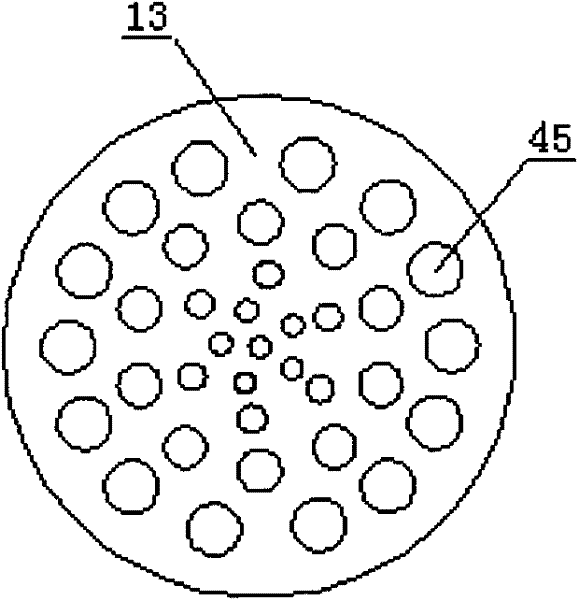

[0028] In the integrated tank 48, there are also secondary slag outlets 14 and tertiary slag outlets 47 in sequence from top to bottom;

[0029] The slag collecting plate 5 an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com