Hydrogen production technology and generation device with high efficiency

A generation device, high-efficiency technology, applied in the direction of cells, electrolysis process, electrolysis components, etc., can solve the problems of uneconomical, complex system structure, high energy consumption, and achieve high hydrogen production efficiency, enlarged surface area, and high hydrogen production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

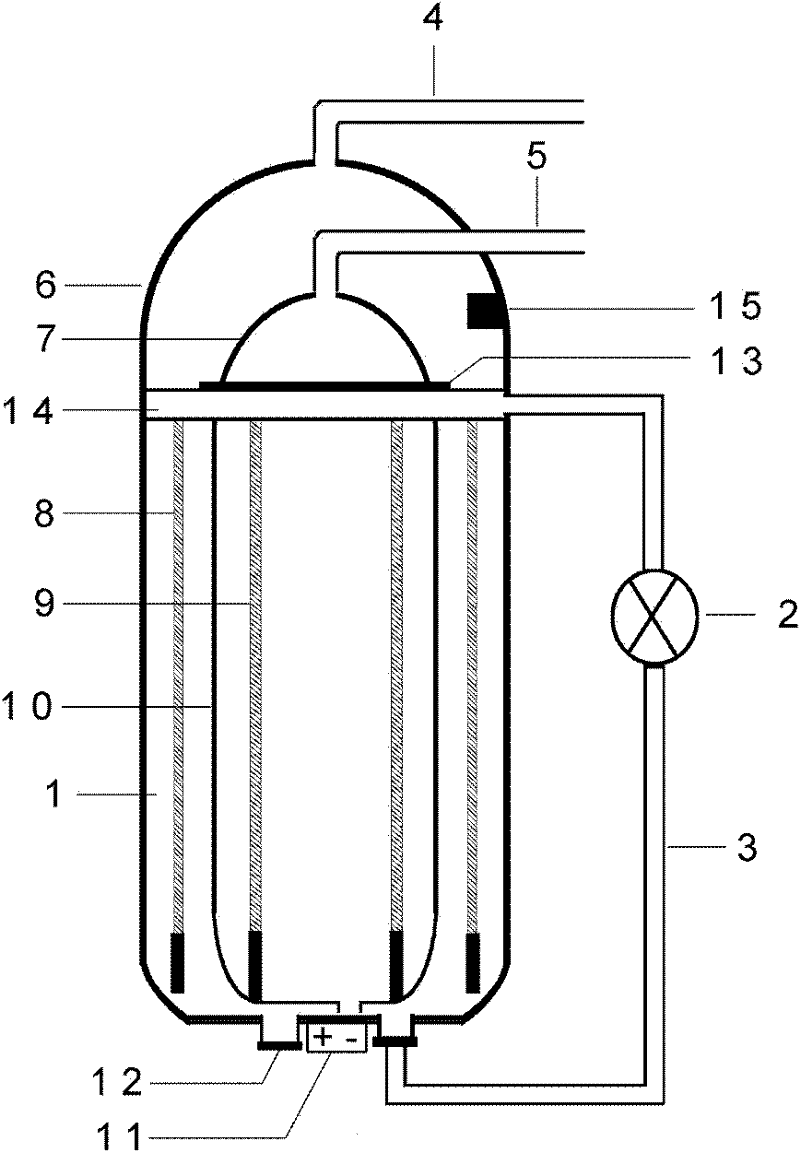

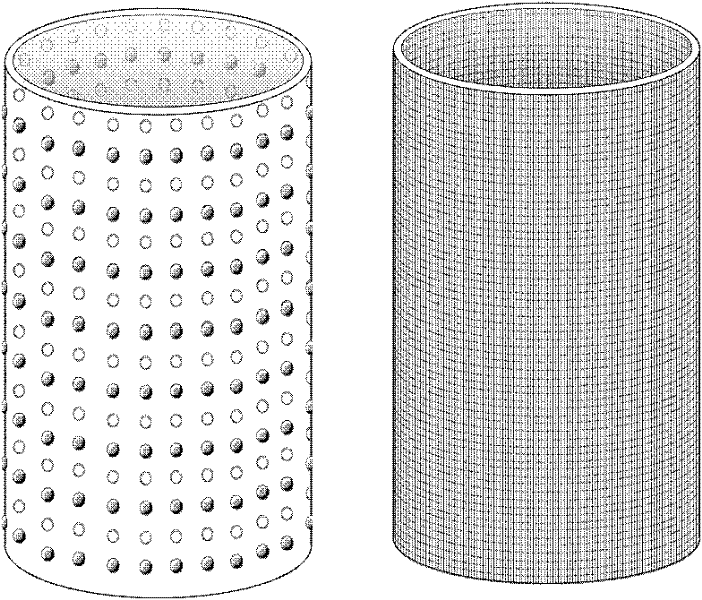

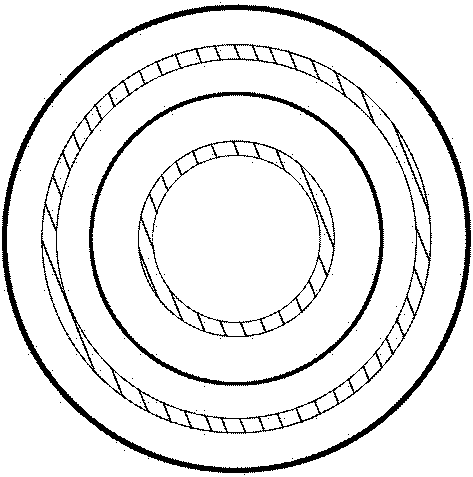

[0019] Specific implementation methods, such as figure 1 As shown, a cylindrical anode plate (9) with a diameter of 29 cm and a height of 20 cm is installed in a cylindrical cathode plate (8) with a diameter of 30 cm and a height of 20 cm. A separator (10) coaxial with the anode and cathode (8, 9) is placed between them. A tubular structure divides the electrolysis chamber into an anode subchamber and a cathode subchamber from a separation membrane, which serves to seal the passage of gas therethrough.

[0020] Oxygen gas collector (7) hemispherical sealing cover is installed on cylindrical metal mesh anode (9) and separation membrane (10) upper end. The mist nozzle device (13) is installed on the upper end of the cylindrical metal mesh anode (9), and is sealed together by the sealing cover. The hemispherical sealing cover is the oxygen collector (7). There is an oxygen outlet pipeline (5) at its top. At the end of the oxygen outlet pipeline (5) is an oxygen outlet. The h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com