Realization method of cai combustion based on engine controllable exhaust back pressure valve

A technology of exhaust back pressure and realization method, applied in the direction of engine control, combustion engine, machine/engine, etc., can solve the problems of low internal EGR rate, inability to meet, inability to achieve CAI combustion, etc., to reduce emissions and increase temperature , the effect of improving fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

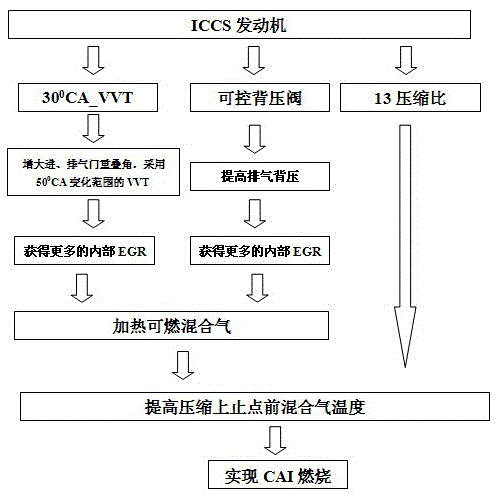

[0015] figure 1 It is a schematic diagram of the process of the CAI combustion realization method based on the engine controllable exhaust back pressure valve of the present invention.

[0016] like figure 1 As shown, the realization method based on engine controllable exhaust back pressure valve CAI combustion of the present invention comprises the following steps: the intake valve of the engine is opened, and air is sucked into the engine; Increase the change angle of VVT to 50°CA; re-inhale part of the exhaust gas generated by combustion in the previous working process of the engine into the cylinder of the engine; change the exhaust back pressure of the engine through the controllable back pressure valve, Control the amount of residual exhaust gas inside the engine; inject fuel into the cylinder of the engine to form a mixed gas with the inhaled...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com