Thermostatic equipment and control method thereof

A constant temperature equipment and equipment technology, which is applied in the direction of using electric mode for temperature control, auxiliary controller with auxiliary heating device, etc., can solve the problem of cumbersome and unsuccinct control method of control system, difficult to achieve better control accuracy and production cost. Advanced problems, to achieve the effect of simple and effective control method, reduced processing cost and processing requirements, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

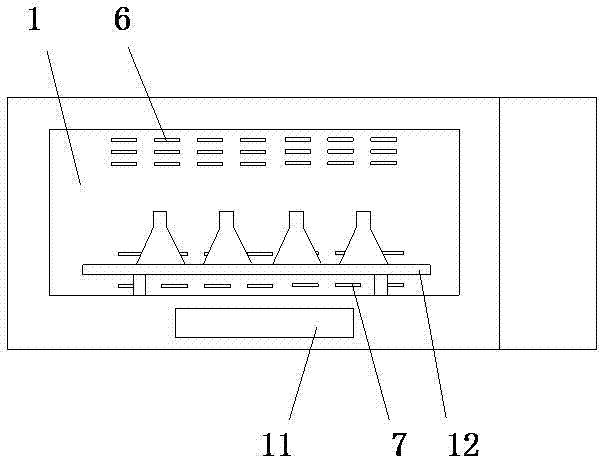

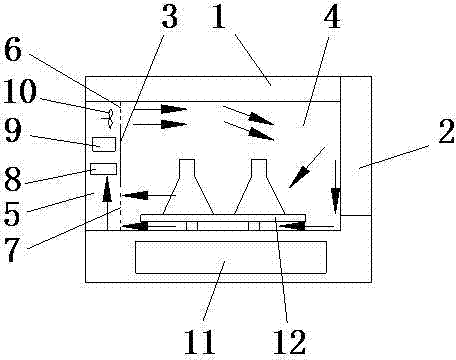

[0034] like Figure 1 to Figure 3 As shown, a constant temperature oscillator includes a box body 1 with a control system and an oscillation mechanism 11 and a box door 2, and a working chamber 4 and an air duct 5 are formed in the cavity of the box body 1 through a partition plate 3, The air duct 5 is located at the rear of the working chamber 4, the bottom of the working chamber 4 is provided with a rocking plate 12, and the rocking plate 12 is driven to vibrate by the oscillating mechanism 11. The air inlet 6 of the air passage 5 and the working chamber 4, the lower part of the dividing plate 3 is evenly distributed with a plurality of air outlet holes 7 for connecting the air passage 5 and the working chamber 4, and the air passage 5 is sequentially arranged from bottom to top. There is a refrigeration system 8, a heating system 9 and a fan 10. In this embodiment, the refrigeration system 8 is an evaporator, and the heating system 9 is a heating pipe.

[0035] When the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com