Horizontal multi-stage thermal parallel thermoelectric conversion pile

A thermoelectric conversion, horizontal technology, used in thermoelectric devices that only utilize the Peltier or Seebeck effect, machine operation, lighting and heating equipment, etc., to improve efficiency, reduce energy consumption, and overcome fatal flaws.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

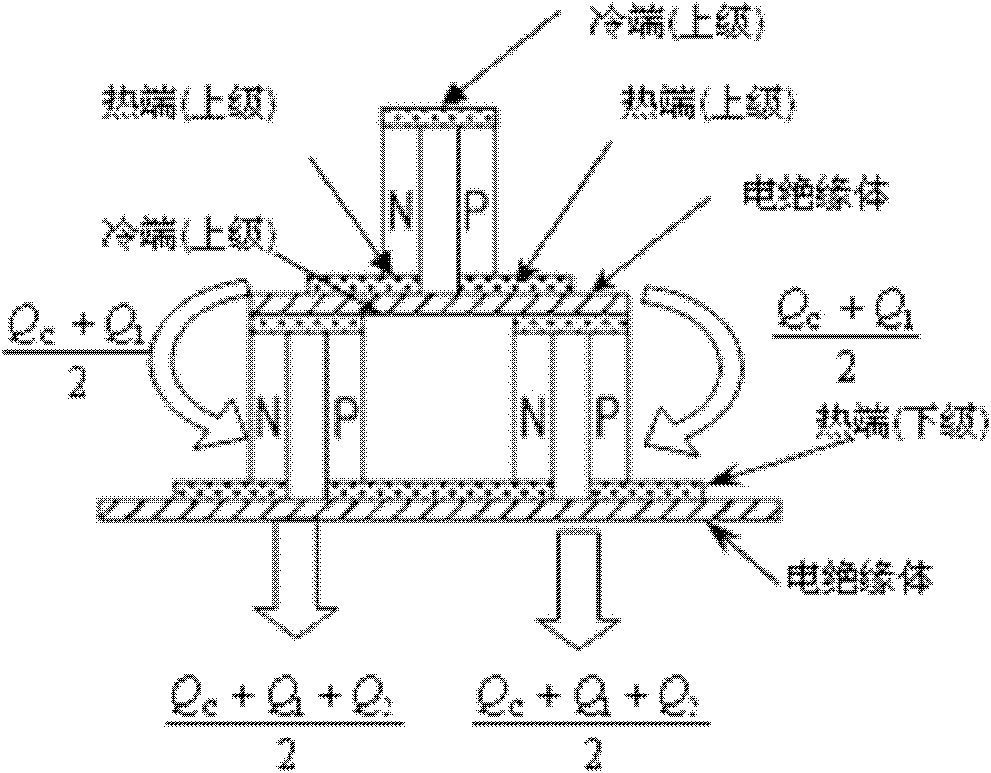

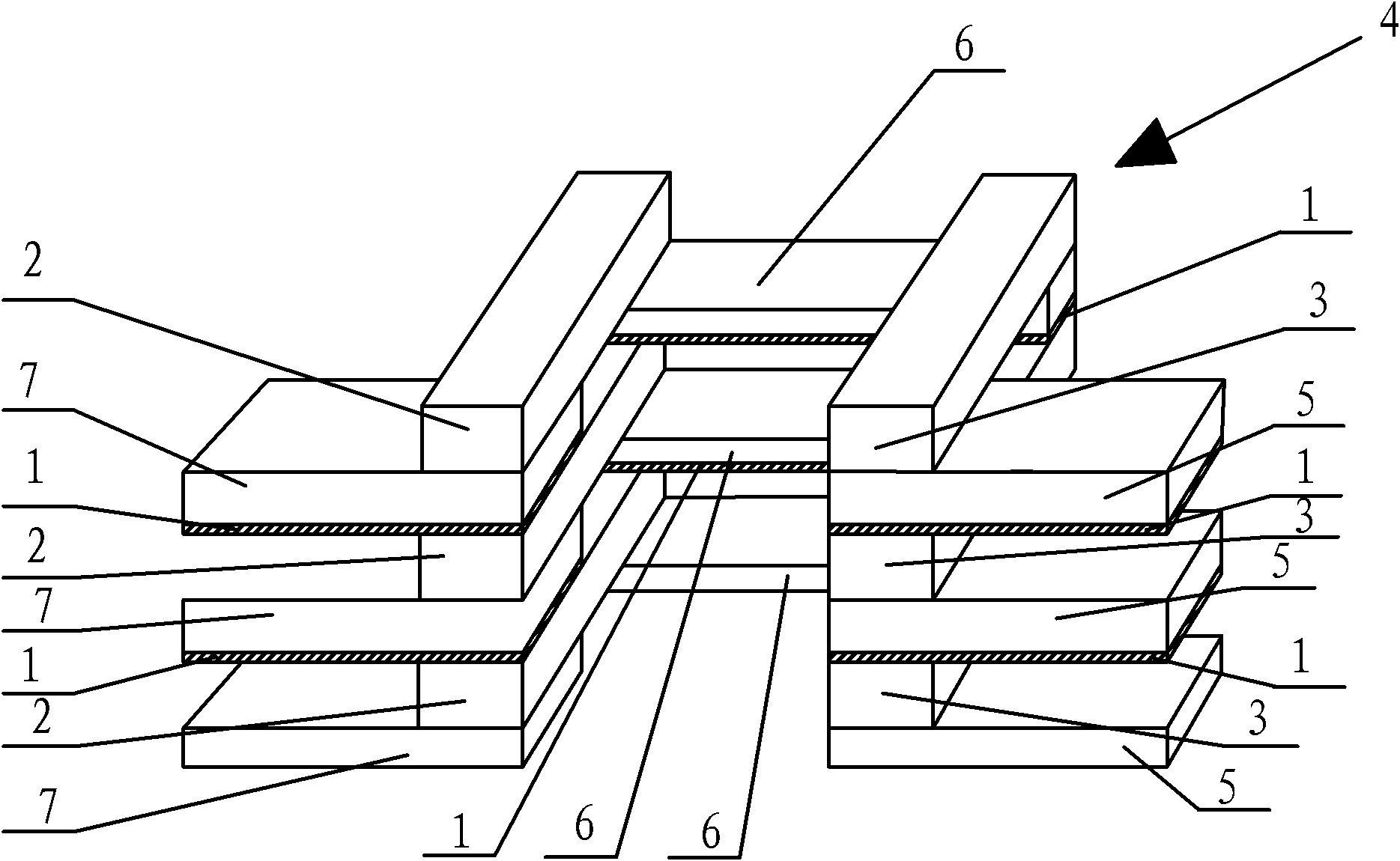

[0032] Example: such as figure 2 It includes a plurality of thermoelectric conversion units 4 composed of N-type thermoelectric semiconductors 2, P-type thermoelectric semiconductors 3 and metal sheets, and a thermally conductive and electrically insulating layer 1 located between adjacent thermoelectric conversion units 4. Two adjacent thermoelectric conversion units The working ends 8 of 4 are laminated and connected to each other through the thermally conductive and electrically insulating layers 1 . In each thermoelectric conversion unit 4, one end of the P-type thermoelectric semiconductor 3 is connected to the first metal sheet 5, and the other end of the P-type thermoelectric semiconductor 3 is connected to one end of the N-type thermoelectric semiconductor 2 through the second metal sheet 6, and the N-type thermoelectric semiconductor 2 The other end is connected to the third metal sheet 7. The electrical connection between two adjacent thermoelectric conversion unit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com