Graphite-phase carbon and nitrogen compound powder, as well as preparation method and application thereof

A carbon-nitrogen compound, graphite phase technology, applied in the field of environment and clean energy, can solve the problems of low output, difficult to obtain, unfriendly to the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The steps included in the preparation method of the carbonitride powder are as follows:

[0035] Drying: Put 5g of urea into the crucible and dry at a certain temperature;

[0036] Heat treatment: Put the dried samples into the heating furnace. At a heating rate of 3°C / min to 550°C, react at this temperature for 3h to obtain a yellow solid;

[0037] Washing: Put the obtained yellow solid into dilute nitric acid and wash it for 24h under stirring condition. Stop stirring, and remove the supernatant after the powder is completely precipitated. Finally, add deionized water, under stirring conditions, repeat washing 2-3 times and then let it settle;

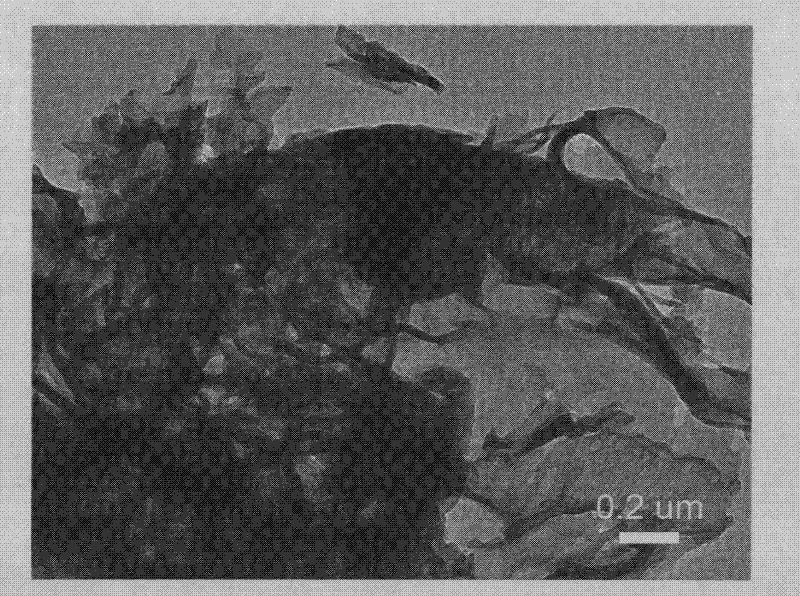

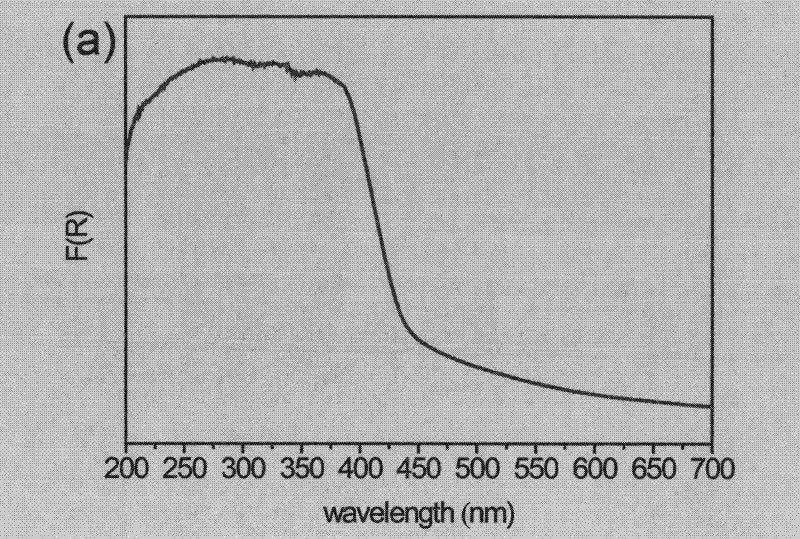

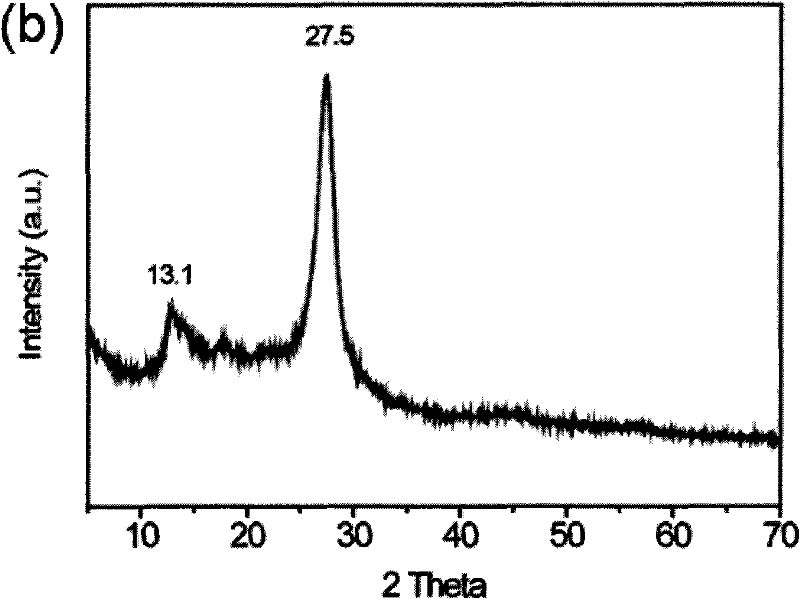

[0038] Filtration and drying: Obtain the settled lower layer powder by filtration, and dry it under reduced pressure at room temperature or at 80°C to obtain the target product in powder form with an average particle size of 500nm. Elemental analysis showed that the ratio of C and N was C:N=0.73.

Embodiment 2

[0040] The steps included in the preparation method of the carbonitride powder are as follows:

[0041] Drying: Put 10g of melamine into the crucible and dry at a certain temperature;

[0042] Heat treatment: Put the dried samples into the heating furnace. At a heating rate of 7°C / min to 550°C, react at this temperature for 3h to obtain a yellow solid;

[0043] Washing: Put the obtained yellow solid into dilute nitric acid and wash it for 24h under stirring condition. Stop stirring, and remove the supernatant after the powder is completely precipitated. Finally, add deionized water, under stirring conditions, repeat washing 2-3 times and then let it settle;

[0044] Filtration and drying: the settled lower layer powder was obtained by filtration, and dried under reduced pressure at room temperature or at 80°C to obtain the target product in powder form with an average particle size of 0.6 μm. Elemental analysis showed that the ratio of C and N was C:N=0.8.

Embodiment 3

[0046] Get the obtained carbonitride powder of embodiment 1 or embodiment 2 and carry it on the glass surface, and its steps are as follows:

[0047] Take 10mg of powder material and ultrasonically disperse it into 100mL ethanol and Nafion solution (0.5mL, 5wt%);

[0048] Take 20mL and apply it to the glass surface of 3cm×6cm by drop casting method;

[0049] Bake and dry under infrared light to form a film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com