Rapid culture method of aerobic granular sludge

A technology of aerobic granular sludge and cultivation method, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve poor operability, complicated operation steps, and low practical application value And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

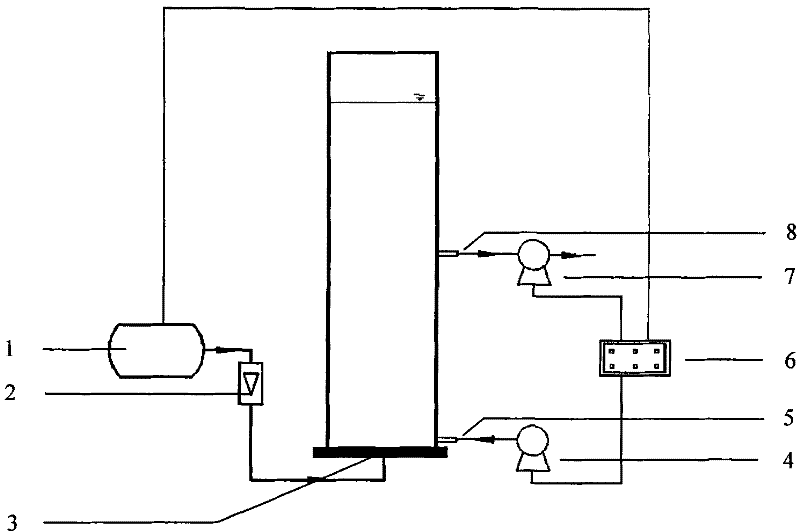

Method used

Image

Examples

Embodiment 1

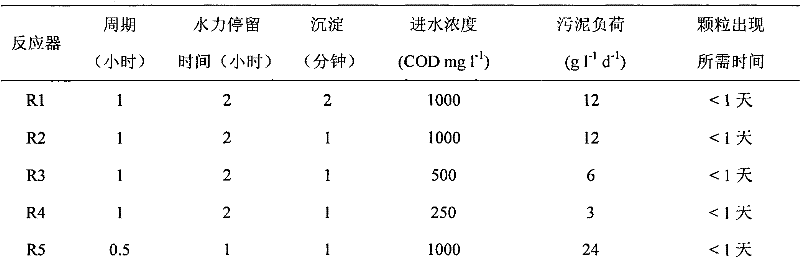

[0026] Example 1: Using synthetic wastewater to cultivate aerobic particles in the laboratory

[0027] Materials and methods

[0028] Reactor start

[0029] The sludge comes from a general municipal sewage treatment plant, and enters the reactor after 4 days of domestication with artificially synthesized distribution water. The working volume of the reactor is 2.0L, and it runs periodically in a sequential batch mode. Synthetic sewage is pumped into the reactor through the water inlet at the bottom of the reactor, and the water inlet time is 5 minutes per cycle. Aeration is realized through the air pump through the bottom of the reactor, and the reactor performs biochemical reactions. After the aeration is stopped, the reactor system enters the settling phase. With a shorter settling time of 5 minutes, the sludge with good settling properties can be retained in the reactor. The effluent after the reaction is discharged through the water outlet located in the middle of the...

Embodiment 2

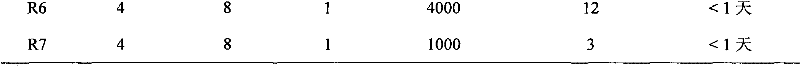

[0038] Example 2: Rapid cultivation of aerobic granular sludge using urban sewage in a pilot-scale reactor

[0039] The ultimate goal of the research on aerobic granular sludge is to realize the practical application of aerobic granular sludge. But so far, the research on aerobic granular sludge is generally based on laboratory-scale cultivation, and there are few researches on pilot scale or above the actual situation. At the same time, there are more factors affecting the cultivation of aerobic granular sludge in the pilot scale or above, so the cultivation time required for the pilot scale or above is often longer than that in the laboratory. At present, in the reported examples of pilot-scale cultivation of aerobic granular sludge, the time required for the cultivation and start-up of granular sludge is sometimes as long as more than one year, which has brought great benefits to the further practical application and promotion of aerobic granular sludge. big difficulty. T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com