Hyperbranched polysiloxane and preparation method thereof

A technology of polysiloxane and trialkoxysilane, which is applied in the fields of hyperbranched polymers and their synthesis, hyperbranched polysiloxanes and their preparation, can solve the problem of limited improvement in flame retardancy and reduction in mechanical properties and other properties. , flame retardant performance and other issues, to achieve the effects of improved mechanical properties, improved limiting oxygen index, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

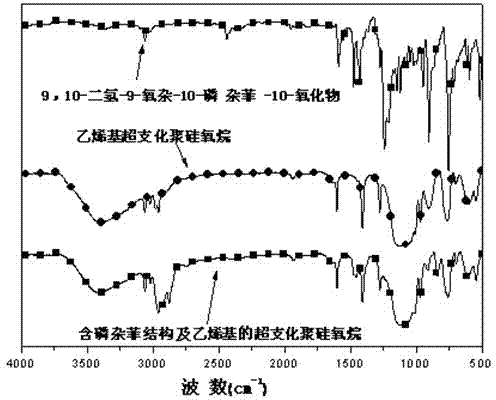

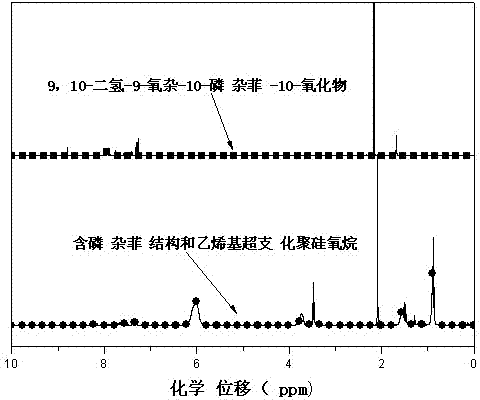

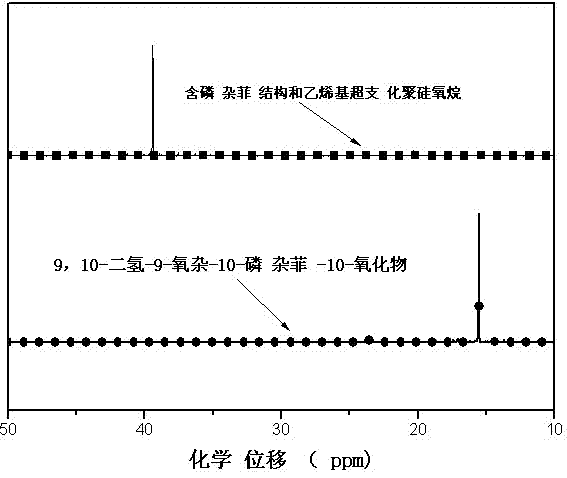

Method used

Image

Examples

Embodiment 1

[0026] After mixing 1.98g of distilled water with 28.0g of vinyl-tris(2-methoxyethoxy)silane (0.1mol vinyl content), slowly add 1mL of 36.5% mass concentration of HCl; After the dropwise addition, the temperature was raised to 50° C. to continue the reaction for 4 hours; after the reaction was completed, vacuum drying was carried out to obtain a transparent and viscous vinyl-containing hyperbranched polysiloxane.

[0027] The prepared vinyl-containing hyperbranched polysiloxane (vinyl content 0.1mol), 2.16g (0.01mol) of 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxidized After the compound was mixed evenly with 120mL of propanol, 0.4g of azobisisobutyronitrile was added, heated to 95°C and continued to react for 5 hours, and the crude product was obtained by distillation under reduced pressure.

[0028] After the crude product is purified, filtered, vacuum-distilled, and vacuum-dried, a hyperbranched polysiloxane containing a phosphaphenanthrene structure and a vinyl group i...

Embodiment 2

[0046] Take 3.24g of distilled water and 28.0g (0.1mol vinyl content) of vinyl-tris(2-methoxyethoxy)silane and mix evenly, then slowly add 1mL of 36.5% HCl dropwise at room temperature with stirring; After the dropwise addition, the temperature was raised to 70° C. to continue the reaction for 4 hours; after the reaction was completed, vacuum drying was carried out to obtain a transparent and viscous vinyl-containing hyperbranched polysiloxane.

[0047] Get all the above-mentioned vinyl-containing hyperbranched polysiloxanes (0.1mol vinyl content), 18.44g (0.09mol) 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and After mixing 120mL of ethanol evenly, add 0.6g of azobisisoheptanonitrile, heat to 100°C and continue the reaction for 10 hours, and distill under reduced pressure to obtain the crude product;

[0048] After the crude product is purified, filtered, distilled under reduced pressure and dried in vacuum, the hyperbranched polysiloxane containing phosphaphenanthrene...

Embodiment 3

[0050] Take 2.34g of distilled water and 28.0g (0.1mol vinyl content) of vinyl-tris(2-methoxyethoxy)silane and mix evenly, then slowly add 1mL of 36.5% HCl dropwise at room temperature with stirring; After the dropwise addition, the temperature was raised to 55° C. to continue the reaction for 5 hours; after the reaction was completed, vacuum drying was carried out to obtain a transparent and viscous vinyl-containing hyperbranched polysiloxane.

[0051] Take all the above vinyl-containing hyperbranched polysiloxane (0.1mol vinyl content), 8.44g 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and mix with 120mL propanol After uniformity, add 0.1 g of azobisisobutylcyanide, heat to 100°C and continue the reaction for 7 hours, and distill under reduced pressure to obtain the crude product;

[0052] After the crude product is purified, filtered, distilled under reduced pressure and dried in vacuum, the hyperbranched polysiloxane containing phosphaphenanthrene structure and viny...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com