Sound-absorbing paint and preparation method thereof

A technology of sound-absorbing paint and raw materials, applied in the field of building decoration materials, can solve the problems of easy damage and high cost, achieve a warm indoor environment, reduce and alleviate noise, and achieve excellent effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

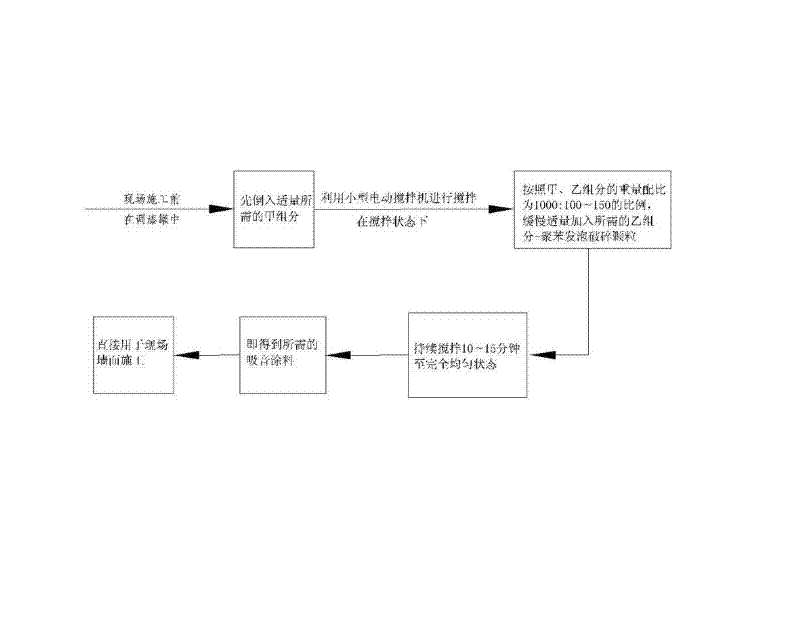

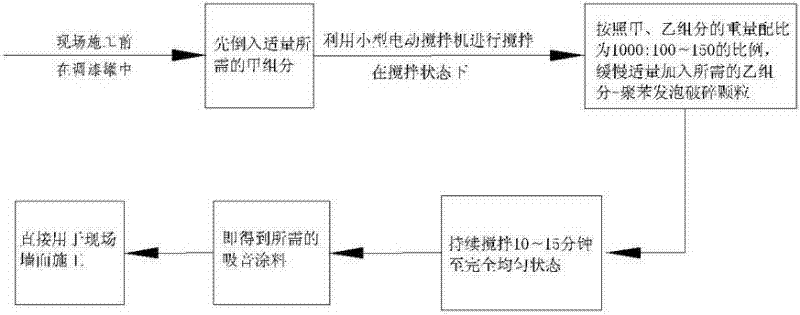

preparation example Construction

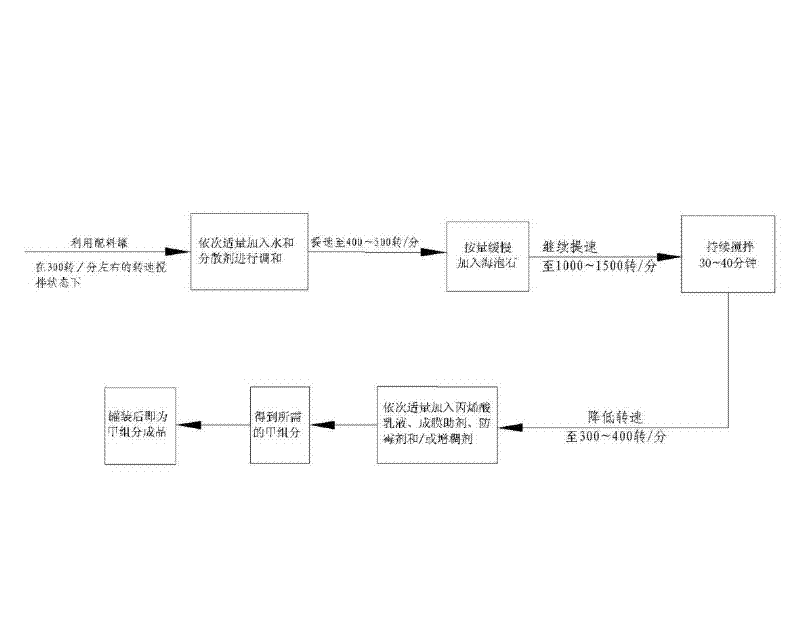

[0037] A kind of preparation method of sound-absorbing coating that the present invention relates to, it mainly comprises the following steps:

[0038] a) Using a batching tank, under the state of stirring at a rotating speed of about 300 r / min, add an appropriate amount of water and dispersant in the raw materials of component A in order to reconcile;

[0039] b) Then increase the speed to 400-500 rpm, and slowly add the sepiolite in the raw material of component A according to the amount;

[0040] c) Continue to increase the speed to 1000-1500 rpm, and keep stirring for 30-40 minutes;

[0041] d) The rotation speed is reduced to 300-400 rpm, and the acrylic emulsion, film-forming aid, anti-fungal agent and thickener in the raw materials of component A are sequentially added, and finally the stirring is continued for 30-40 minutes; the sound-absorbing coating is obtained The required A component;

[0042] e) After being filled in cans, it is the finished product of componen...

Embodiment 1

[0045] The raw materials of component A involved in the sound-absorbing coating of the present invention, its percentage by weight is: 0.5% dispersant, 30% sepiolite, 20% acrylic emulsion, 0.7% film-forming aid, 0.13% thickener and 0.7% fungicide , 47.97% water.

[0046] The weight ratio of components A and B involved in the sound-absorbing coating of the present invention is 1000:100.

[0047] Production can be done in the following steps:

[0048] a) Using a batching tank, under the state of stirring at a speed of 300 r / min, add an appropriate amount of water and dispersant in the raw materials of component A in sequence for blending;

[0049] b) Afterwards, increase the speed to 400 rpm, and slowly add the sepiolite in the raw material of component A according to the amount;

[0050] c) Continue to increase the speed to 1000 rpm, and keep stirring for 30 minutes;

[0051] d) The rotation speed is reduced to 300 rpm, and the acrylic emulsion, film-forming aid, antifungal ag...

Embodiment 2

[0055] The raw materials of component A involved in the sound-absorbing coating of the present invention, its percentage by weight is: dispersant 0.1%, sepiolite 15%, acrylic acid emulsion 35%, film-forming aid 0.8%, thickener 1.5% and antifungal agent 0.8% , water 46.8%;

[0056] The weight ratio of components A and B involved in the sound-absorbing coating of the present invention is 1000:125.

[0057] Production can be done in the following steps:

[0058] a) Using a batching tank, under the state of stirring at a rotational speed of 295 r / min, add an appropriate amount of water and dispersant in the raw materials of component A in order to reconcile;

[0059] b) Afterwards, increase the speed to 450 rpm, and slowly add the sepiolite in the raw material of component A according to the amount;

[0060] c) Continue to increase the speed to 1100 rpm, and keep stirring for 35 minutes;

[0061] d) The rotation speed is reduced to 350 rpm, and the acrylic emulsion, film-formin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com