Preparation method of gallium nitride single crystal

A technology of gallium nitride single crystal and gallium nitride crystal, which is applied in the field of preparation of gallium nitride single crystal, can solve the problems of high manufacturing cost and unfavorable large-scale industrial production, and achieve the effect of low manufacturing cost and easy realization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

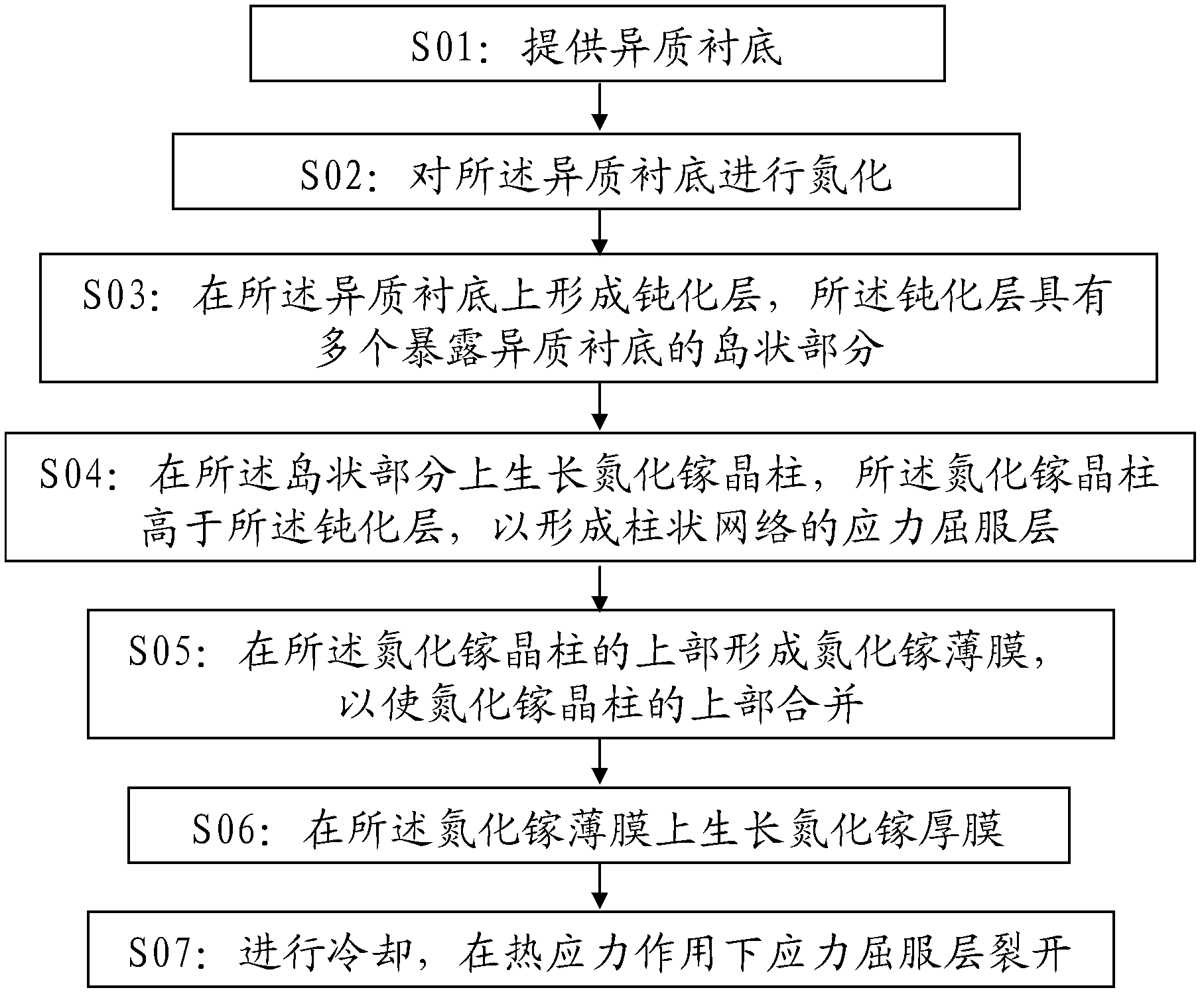

[0036] Based on this, the present invention adopts a heterogeneous substrate. Before forming a gallium nitride thick film, the stress yield layer of the columnar network is formed by forming gallium nitride crystal columns. The thermal stress in the cooling process makes the growth on the heterogeneous substrate The gallium nitride single crystal on the substrate is cracked in the stress yield layer, so as to realize the self-stripping of the gallium nitride thick film and the heterogeneous substrate, and reduce the manufacturing cost. The preparation method of the gallium nitride single crystal includes:

[0037] Provide heterogeneous substrates;

[0038] Nitriding the foreign substrate;

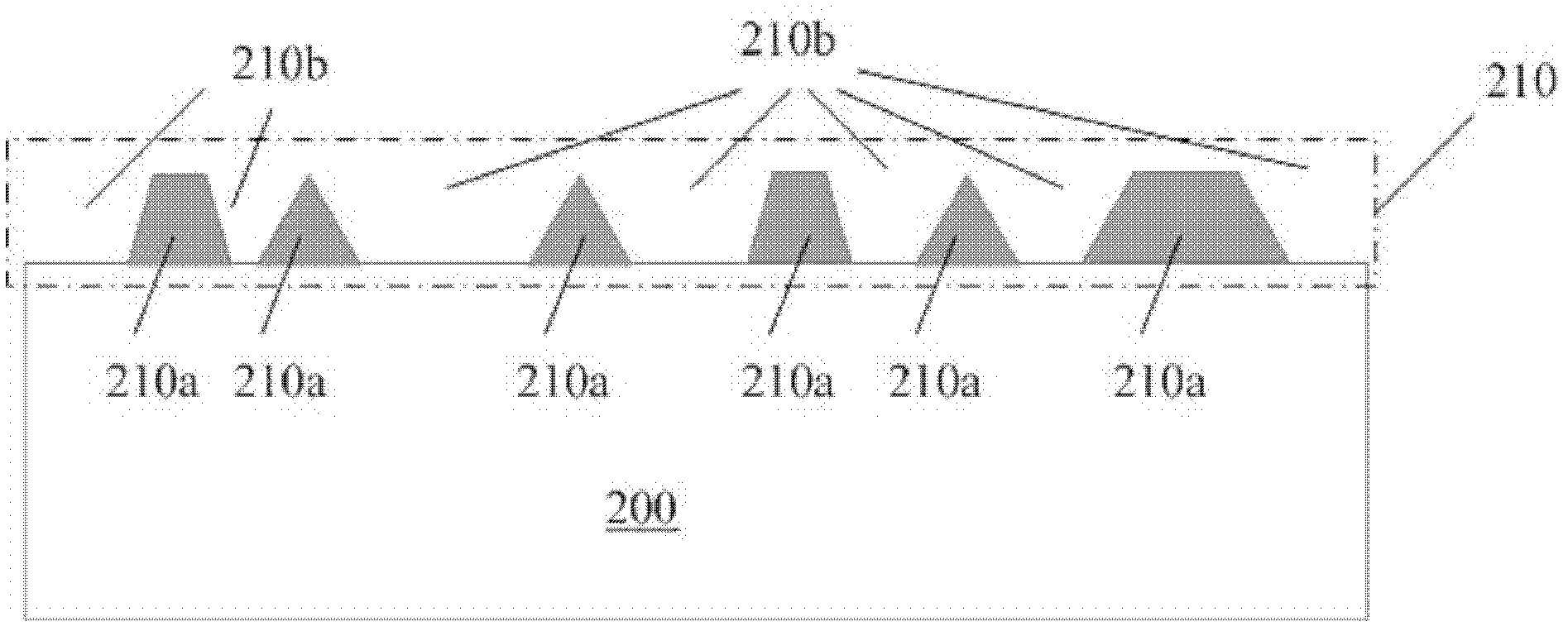

[0039] forming a passivation layer on the foreign substrate, the passivation layer having a plurality of island-like portions exposing the foreign substrate;

[0040] growing gallium nitride crystal pillars on the island portion, the gallium nitride crystal pillars being higher than the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com