Intrinsic optical fiber Fabry-Perot temperature sensor manufactured by femtosecond pulse laser and manufacturing method of temperature sensor

A technology of temperature sensor and femtosecond pulse, which is applied in the direction of physical/chemical change thermometers, thermometers, cladding optical fibers, etc., can solve problems such as difficult reuse, restrict rapid development, complex manufacturing process, etc., to ensure integrity, The effect of improving the ability to resist harsh environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

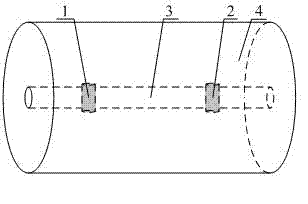

[0025] see figure 1 , the intrinsic fiber-optic F-P temperature sensor prepared by the present femtosecond pulsed laser, including an optical fiber (4), in which there is a first optical fiber internal reflection mirror (1) and a second optical fiber internal reflection mirror (2), The first optical fiber internal reflection mirror (1) and the second optical fiber internal reflection mirror (2) are respectively formed by changing the refractive index at the core of the single-mode optical fiber core (3) along the radial direction of the femtosecond pulsed laser; The distance between the first optical fiber internal reflection mirror (1) and the second optical fiber internal reflection mirror (2) is 50-5000 μm.

Embodiment 2

[0027] The manufacturing method of the intrinsic fiber-optic F-P temperature sensor prepared by the femtosecond pulse laser is used to make the intrinsic-type fiber-optic F-P temperature sensor prepared by the femtosecond pulse laser described in Embodiment 1, and its operation method is as follows:

[0028] 1) Place the optical fiber (4) on the three-dimensional mobile platform so that the axis of the optical fiber (4) is perpendicular to the transmission direction of the femtosecond pulse laser;

[0029] 2) The femtosecond pulsed laser is focused on the fiber core through the objective lens of the microscope;

[0030] 3) The three-dimensional mobile platform moves along the transmission direction of the femtosecond pulsed laser, so that the focal point of the femtosecond pulsed laser scans the fiber core along the radial direction of the fiber;

[0031] 4) When making a fiber optic internal mirror, the moving distance of the three-dimensional mobile platform is 12 μm, and th...

Embodiment 3

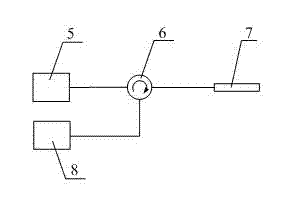

[0033] see figure 2 , an intrinsic fiber optic F-P temperature sensing device, comprising a light source (5), the light source (5) connected to a fiber optic circulator (6), and an interface of the fiber optic circulator (6) connected to an embodiment 1 The intrinsic fiber optic F-P temperature sensor (7) prepared by the femtosecond pulsed laser, another interface is connected to a spectrum analyzer (8); the light source (5) shown is a 1550nm broadband light source, and a fiber optic circulator (6) It is a 1550nm fiber optic circulator; the light emitted by the light source (5) is guided through the fiber optic circulator (6) into an intrinsic fiber-optic F-P temperature sensor (7) prepared by a femtosecond pulse laser; The intrinsic type optical fiber F-P temperature sensor (7) finally displays the collected external temperature signal on the optical spectrum analyzer (8) through the optical fiber circulator (6).

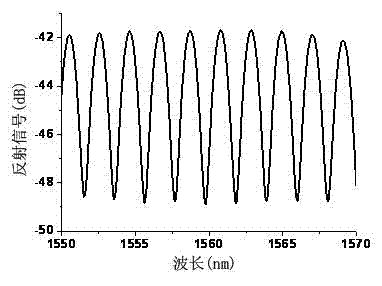

[0034] image 3 and Figure 4 These are the reflection in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com