Tester for concrete free deformation

A free-deformation, concrete technology, applied in the field of testers, can solve the problems of not being able to measure free deformation, not considering the influence of deformation, and unable to measure deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

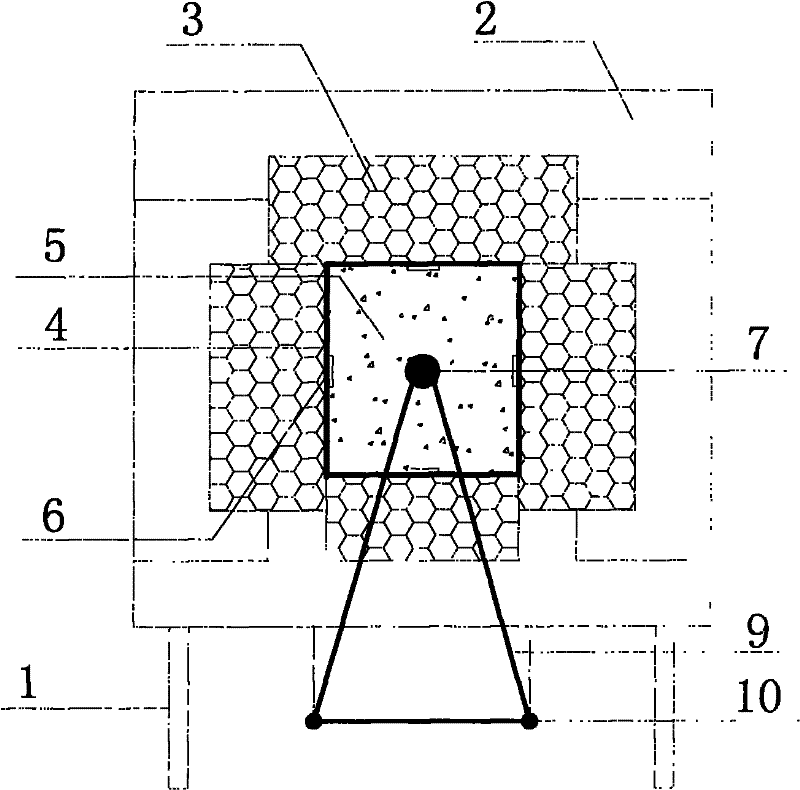

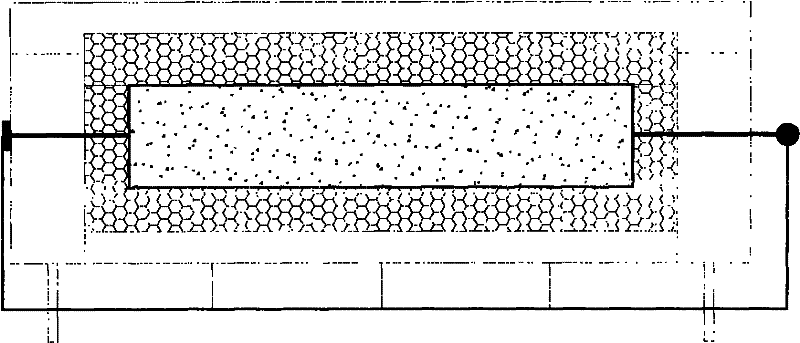

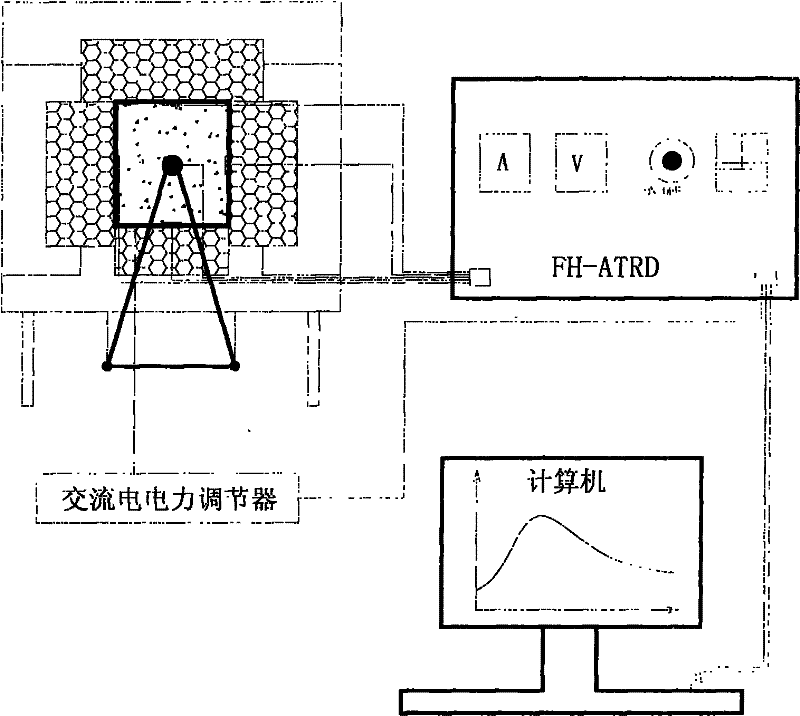

[0019] Such as figure 1 , 2 As shown, the concrete test object 5 is poured into the concrete free deformation tester of the present invention after mixing, and a deformation measuring support 9 is provided under the tester. Before pouring the concrete, the front and rear side panels of the concrete free deformation tester need to be returned to their positions, so that they are combined with the left and right side panels and the bottom side panels into a sealed state, and then lay the plastic film to reduce friction, and then stir evenly The concrete is poured into it, the position of the temperature sensor 6 is fixed, and the top side plate is covered to form a closed container. The six board surfaces 2 of the left and right, front and rear side panels, the upper side panel and the lower side panel are all embedded in a honeycomb thermal insulation layer 3, and the thermal insulation layer 3 is provided with a silicon rubber heating film 4 close to the side of the test piece. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com