Welding method of vertically brazed joint of stainless steel conduit

A technology of brazing joints and welding methods, which is applied in the welding field of vertical brazing joints of stainless steel conduits, and can solve problems affecting product quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

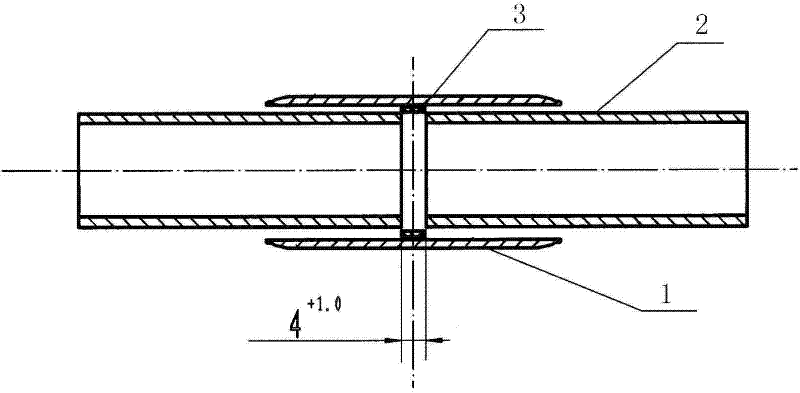

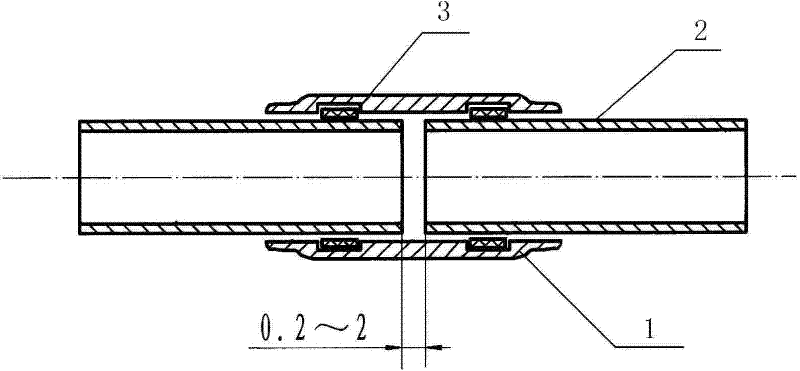

[0014] A welding method for brazing joints in the vertical direction of stainless steel conduits, characterized in that the steps are as follows:

[0015] 1) Preparation of the joint surface before brazing: matt nickel plating is carried out within a length not less than 50mm from the end of the conduit. After nickel plating, the surface is a uniform, matte dark silver-white surface, and the thickness of the nickel plating layer is 6-9mm. , the outer diameter tolerance is d-0.05 -0.1mm, the surface roughness is not less than Ra3.2mm;

[0016] 2) Preparation of solder ring: the thickness of the solder ring is 0.25mm, and the width is 1.5-3mm;

[0017] 3) Preparation of the casing: nickel-plate the surface of the casing completely, and the inner diameter of the casing after nickel plating is D+0.1+0.05mm, and the rest are the same as the requirements of the catheter;

[0018] 4) Assembly between parts: the conduit is sleeved in the casing, and the offset relative to the center ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com