Gas chromatography-mass spectrum/olfactometry (GC-O-MS) assisted preparation method for strengthened thermal response savory flavoring

A technology of thermal reaction and smelling, which is applied in the field of edible flavor simulation, can solve the problems that hinder the precision of high-quality enhanced heat-reactive salty flavor, high-fidelity production, high requirements for flavoring personnel, and poor purpose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

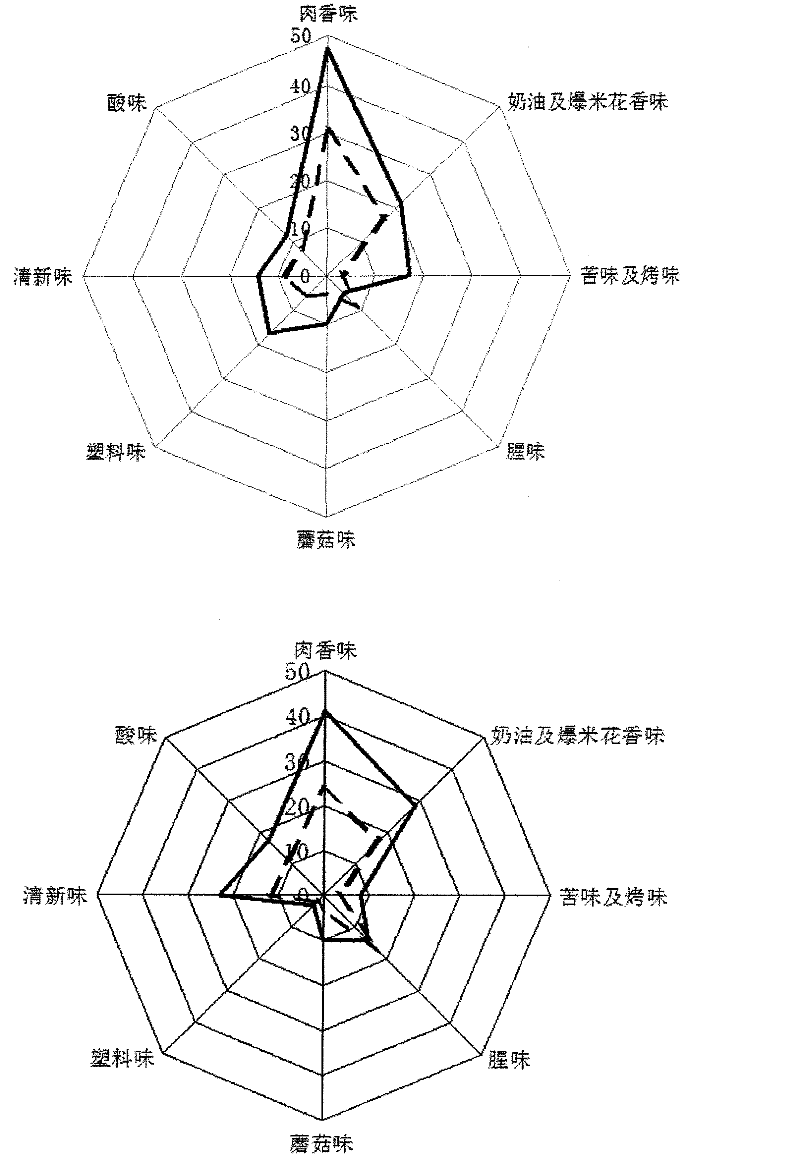

[0018] Embodiment 1 prepares Tong'an sealed meat dish essence

[0019]The dynamic headspace sample preparation (DHS) method was used to extract the flavor active substances in Tong'an sealed meat. The method was equilibrated for 60 minutes, the heating temperature was 40°C, the heating and purging time was 60 minutes, and the nitrogen purging flow rate was 100ml / min. Volatile compounds were separated using DB-Wax. The characteristic flavor substances were analyzed by DHDA method, and the flavor substances with OAV value greater than 1 were 2-methyl-3-furanthiol and so on. Dissolve the above substances in proportion to 10ml of propylene glycol to make fortified essential oil. The production method of the heat-reactive meat-flavored base is (1) mince lean pork and pork fat respectively, heat the lean pork at 90°C for 20 minutes to denature the protein; (2) enzymolyze the pork with 0.2% PSM500 at 65°C Stir continuously for 40 minutes, then heat at 90°C for 10 minutes without st...

Embodiment 2

[0020] Embodiment 2 prepares ginger mother duck dish essence

[0021] Utilize dynamic headspace sample preparation (DHS) method to extract flavor active substance in ginger female duck, the method is equilibrated for 60min, heating temperature is 40 ℃, heating and purging time is 1h, nitrogen purging flow rate is 100ml / min, Volatile compounds were separated using DB-Wax. The characteristic flavor substances were analyzed by DHDA method, and the flavor substances with OAV value>1 were hexanal and so on. The production method of the heat-reactive meat flavor base is (1) mince duck lean meat and duck fat respectively, heat the duck lean meat at 90°C for 20 minutes to denature the protein; (2) enzymolyze the pork with 0.2% PSM500 at 65°C Stir continuously for 40 minutes, then heat at 90°C for 10 minutes to inactivate the enzyme, then cool it down to room temperature rapidly; (3) conduct a heat reaction at 115°C for 30 minutes to make fragrance base, the proportion of reactants ad...

Embodiment 3

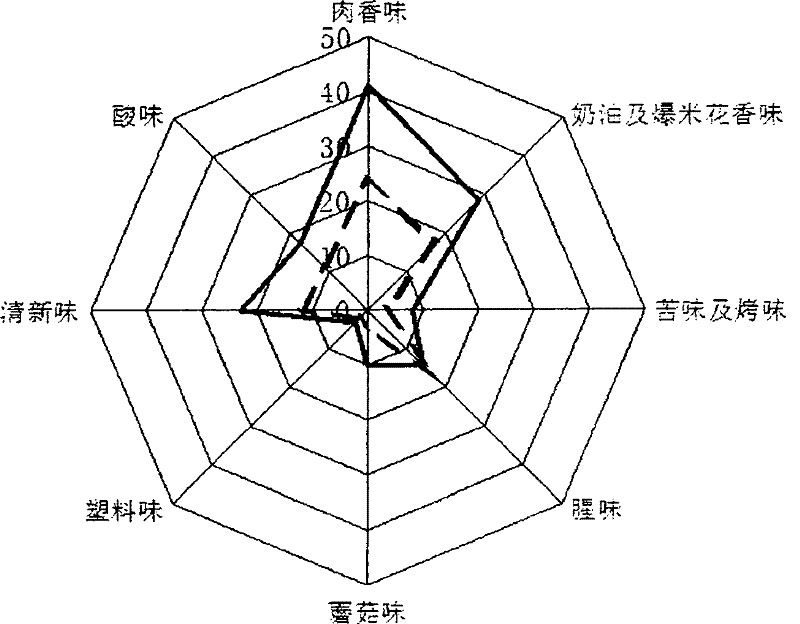

[0022] Embodiment 3 prepares ham essence

[0023] GC-O detection: The obtained ham essence base material was analyzed by aroma analysis technology GC-O, using SDE-GCO (simultaneous distillation extract-sniffing) and DHS-GCO (dynamic headspace sample preparation-sniffing) Methods The aroma components were analyzed. At the same time, aroma extract dilution analysis (AEDA) was used to determine the contribution of various aroma active compounds to the flavor, and to screen the key aroma compounds. The key aromatic compounds were identified as 2-methyl-3-furanthiol, dimethyl trisulfide, 1-octen-3-one, toluene, 3-methylbutyraldehyde, 2-methylthiopropanal (methanal Thialdehyde), butyl acetate, 2-nonenal, octanal, etc. The preparation method of the heat-reactive meat flavor base is (1) enzymatic hydrolysis of Xuanwei ham: the fine meat part of Xuanwei ham is cut into pieces, ground and then added with water to make a ham aqueous solution, wherein ham accounts for 40% of the total ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com