Fully-automatic crystal gemstone polishing method and equipment

A fully automatic, gemstone technology, used in grinding/polishing equipment, metal processing equipment, grinders, etc., can solve the problems of difficult operation, high rejection rate, slow manual operation, etc., to improve product quality and output, easy to operate , the effect of quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

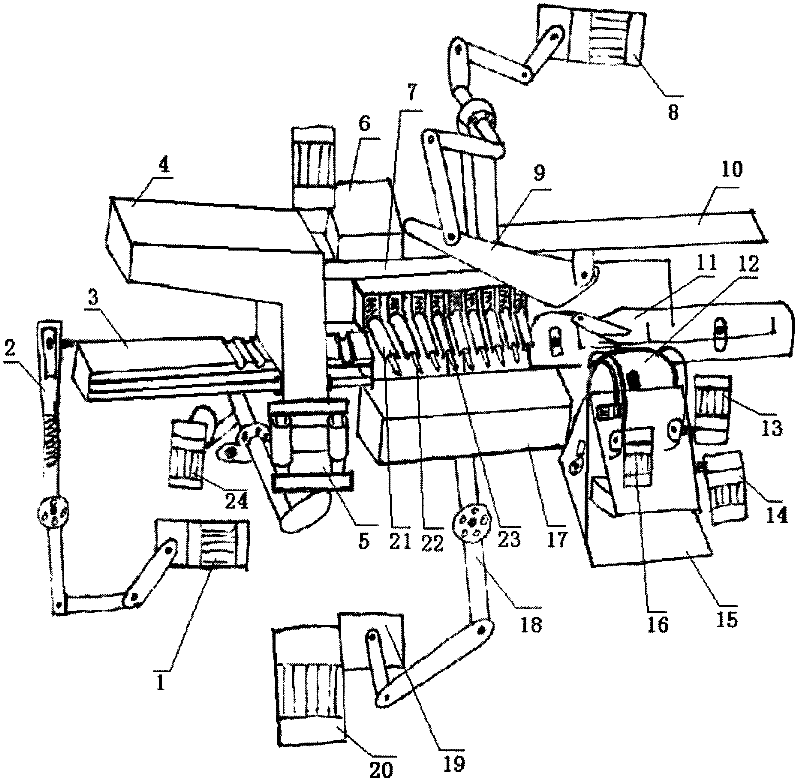

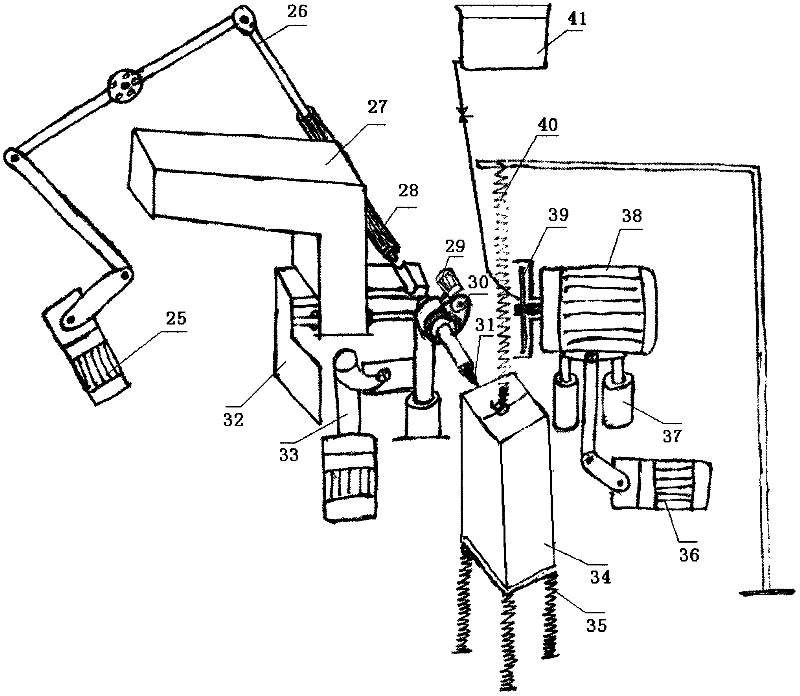

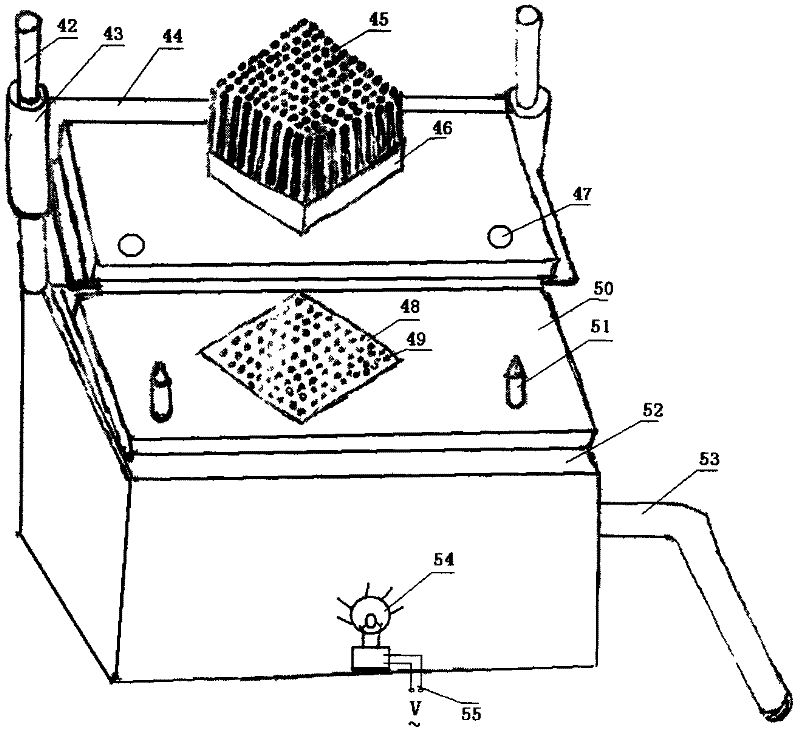

[0045] Such as figure 1Shown: The reciprocating mobile noodle grinding machine includes a frame, an automatic rod loader, a reciprocating movement mechanism, a mechanism for changing the grinding angle, a disc mechanism and an automatic rod removal mechanism. The device is installed at one end of the reciprocating mechanism, and beside the reciprocating mechanism, there is a disc and a concave-convex plate that adapt to the angle of the sticky rod, and the automatic rod removal mechanism is installed above the reciprocating mechanism; wherein the automatic rod loading device includes a hopper 4, a material pushing motor 1. The push rod 2 and the slide plate 3, the hopper 4 is installed on the top of the slide plate 3, and the sticky rod 22 equipped with the ground surface and the ground bottom is dropped from the hopper to the slide plate 3 in order, and the push rod 2 pushes the slide plate 3 to the reciprocating movement mechanism; The reciprocating mechanism includes a reci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com