Circulating feeding system for producing ceramic wall and flow tiles

A technology for circulating cloth, wall and floor tiles, applied in the direction of forming conveyors, etc., can solve the problems of affecting the quality of cloth, complex design structure, high manufacturing cost, and achieve the effect of enriching patterns and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

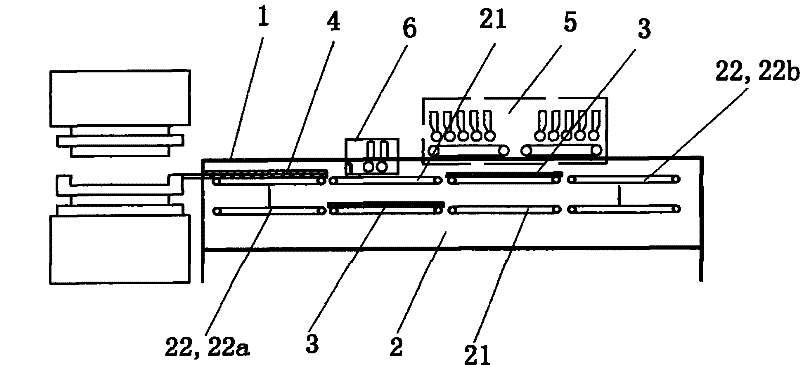

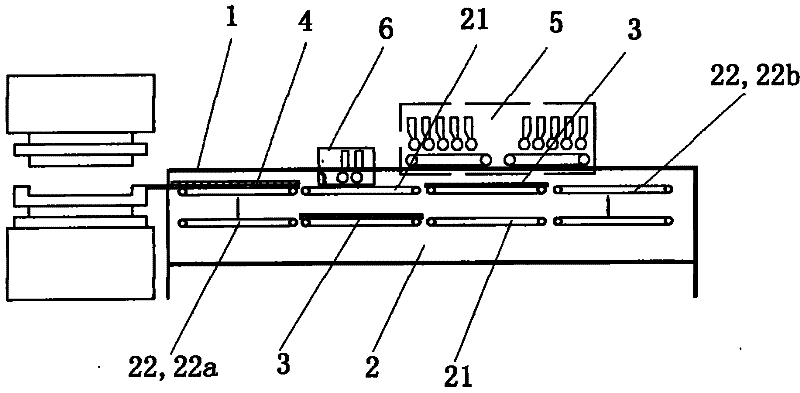

[0010] The present invention as figure 1 As shown, a circulating distribution system for producing ceramic wall and floor tiles includes a frame 1, a conveying device 2, a pallet 3, a feeding device 4, a distributing station device 5, and a replenishing scraping device 6. The above-mentioned conveying device 2 includes a The horizontal conveying platform 21 arranged in upper and lower layers is respectively provided with a liftable vertical conveying platform 22 at the front and rear ends of the horizontal conveying platform 21, and the horizontal conveying platform 21 and the vertical conveying platform 22 together constitute a closed-loop conveying device.

[0011] The above-mentioned horizontal conveying platform 21 arranged in upper and lower layers is respectively composed of several adjacent conveying mechanisms, each conveying mechanism is provided with an independent driving device, and the conveying mechanisms are synchronous or asynchronous conveying. Each section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com