PU elastic paint

A technology of elastic paint and elastic resin, applied in the field of paint, can solve the problem of easy blooming, and achieve the effect of rich hand feeling, soft gloss and uniform color.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

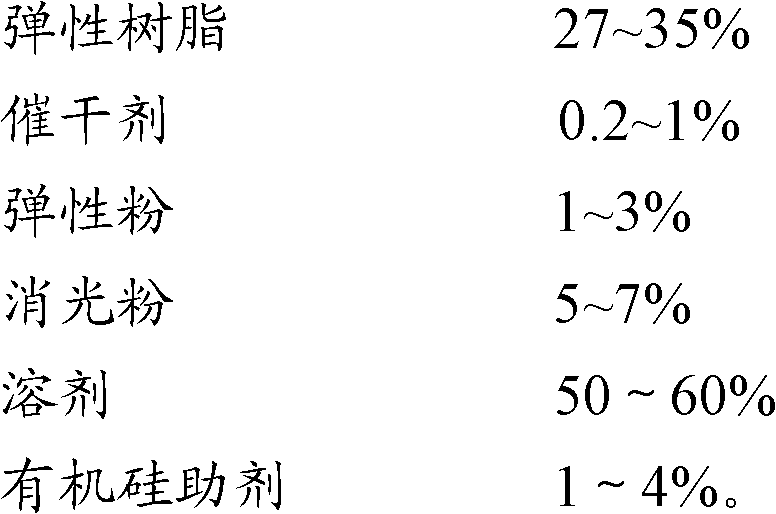

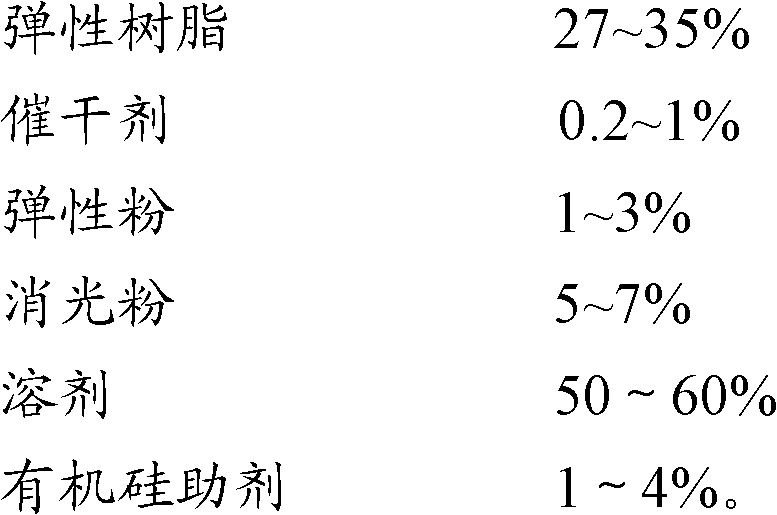

Method used

Image

Examples

Embodiment 1

[0021] 0.4kg drier (American Gas T-12), 4kg organosilicon additive (Zhongshan Jieshida KG-512), 54.6kg mixed solvent of butyl acetate, ethyl acetate and methyl isobutyl ketone (mass The ratio is 2:1.5:1) into the container, disperse evenly with a high-speed disperser, add 6kg of matting powder (OK520) during high-speed dispersion, disperse evenly to a fineness of 25μm, add 2kg of elastic powder (Dainichi Seika 5070D), Disperse evenly at high speed, emulsify until the fineness is less than 25μm, add 33kg of elastic resin (Bayer 1652), and disperse evenly.

[0022] Add 1kg of curing agent (Bayer N3390) to 10kg of main paint, add 3kg of ethyl acetate, diisobutyl ketone and butyl acetate mixed solvent (mass ratio 3.5:0.5:2) to adjust the spray viscosity, and then it can be used for spraying construction.

[0023] The above elastic paint is sprayed on the black ABS substrate, baked at 70-80°C for 30 minutes, the adhesion of the paint film is 5B by the cross-cut method, and the glo...

Embodiment 2

[0025] Mix 0.4kg of drier (American gas T-12), 4kg of organic silicon additive (Shanghai Yile SF-60), 57.6kg of mixed solvent of butyl acetate, ethyl acetate and methyl isobutyl ketone (mass Ratio 2:2:1.5) into the container, disperse evenly with a disperser, add 6kg of matting powder (OK520) when dispersing with a high-speed disperser, disperse evenly until the fineness is less than 25μm, add 30kg of elastic resin (Japan Taisei TX3100) to disperse Evenly, add 2kg of elastic powder (Dainichi Seika 5070D) and continue to disperse for 10 minutes, emulsify until the fineness is less than 25μm.

[0026] Add 1kg of curing agent (Asahi Kasei TPA-90SB) and 3kg of ethyl acetate, toluene, diisobutyl ketone mixed solvent (mass ratio 2:3:1) to 10kg of main paint to adjust the spray viscosity, and then it can be used for spraying construction.

[0027] The above elastic paint is sprayed on the black ABS substrate, baked at 70-80°C for 30 minutes, the adhesion of the paint film is 5B by th...

Embodiment 3

[0029] Mix 0.4kg of drier (American gas T-12), 4kg of organic silicon additive (Shanghai Yile SF-60), 52.4kg of butyl acetate, ethyl acetate and methyl isobutyl ketone (mass ratio 2: Add 1:1) mixed solvent into the container, disperse evenly with a disperser, add 6.2kg of matting powder (OK520) when dispersing with a high-speed disperser, disperse evenly until the fineness is less than 25μm, add 35kg of elastic resin (Japan Taisei TX3100) , The high-speed disperser disperses evenly, add 2kg of elastic powder (Dainichi Seika 5070D) and continue to disperse for 10 minutes, and the emulsifier emulsifies until the fineness is less than 25μm.

[0030] Add 1kg of curing agent (Asahi Kasei TPA-90SB), 3kg of mixed solvent of ethyl acetate, toluene, diisobutyl ketone (mass ratio 3:8:1) to 10kg of main paint to adjust the spray viscosity, and then it can be used for spraying construction.

[0031] The above elastic paint is sprayed on the black ABS substrate, baked at 70-80°C for 30 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com