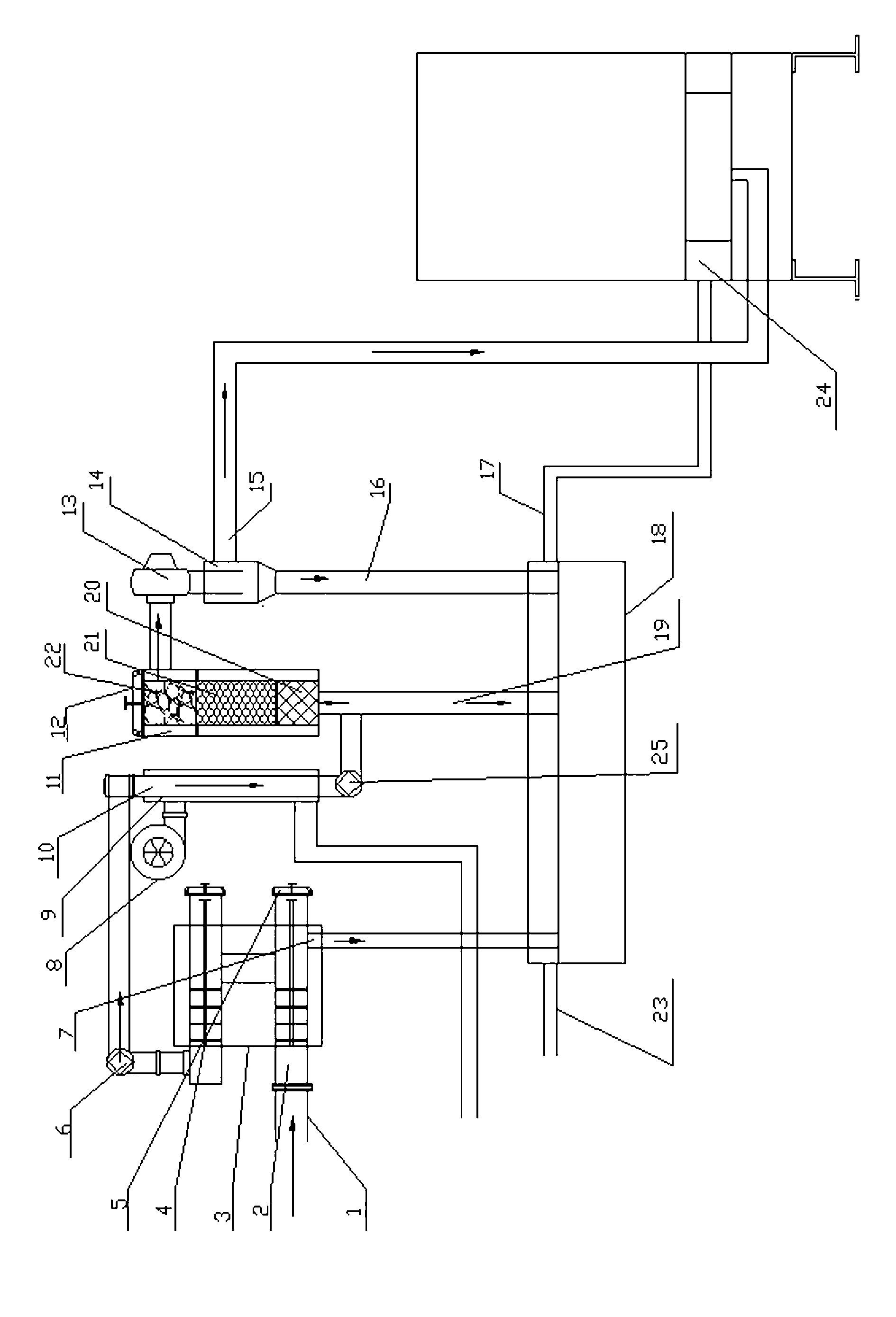

Tar processing and reburning device for household straw gasifier

A combustion device and gasifier technology, which is applied in the petroleum industry, chemical industry, and the manufacture of combustible gas, etc., can solve the problems of odorous tar and water vapor mixture, furnace combustion, and tar blockage, so as to improve the environment and increase heat. value, the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with accompanying drawing.

[0008] refer to figure 1 , a household type straw gasification furnace tar treatment and re-burning device, the household type straw gasification furnace outlet pipe 1 and the inlet end of the first stage cooling air pipe 2 are connected through a flange movable seal, the second The first-level cooling air delivery pipes 2 are placed in parallel in the cooling water tank 3 and the other port is outside the cooling water tank 3 and sealed and locked with a locking cover 5. The multiple first-level cooling air delivery pipes 2 in the cooling water tank 3 are connected to each other. communicated, and the first-stage cooling gas pipeline 2 at the lower part of the cooling water tank 3 communicates with the tar return tank 18 through the pipeline 7, so that the first-stage filtered tar and water vapor mixture flow into the tar return tank 18; The outlet of the cooling air pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com