Saline flow detection device of freezer

A technology of flow detection device and freezer, which is applied in shaft equipment, mining equipment, earth-moving drilling, etc., can solve the problems of leakage of salt water, poor working environment of workers, environmental pollution, etc., and achieve the effect of reducing labor intensity and small investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

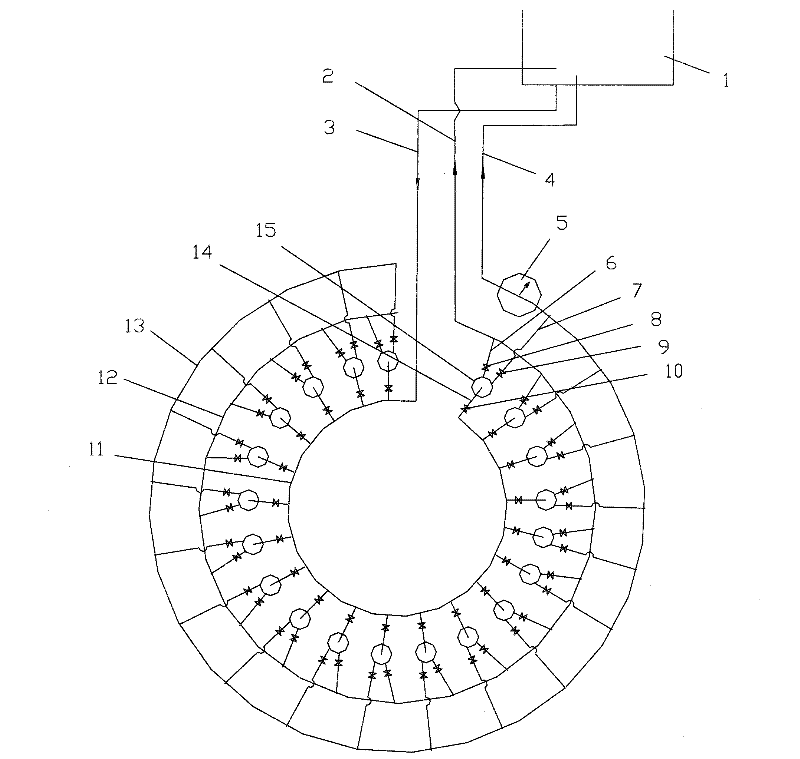

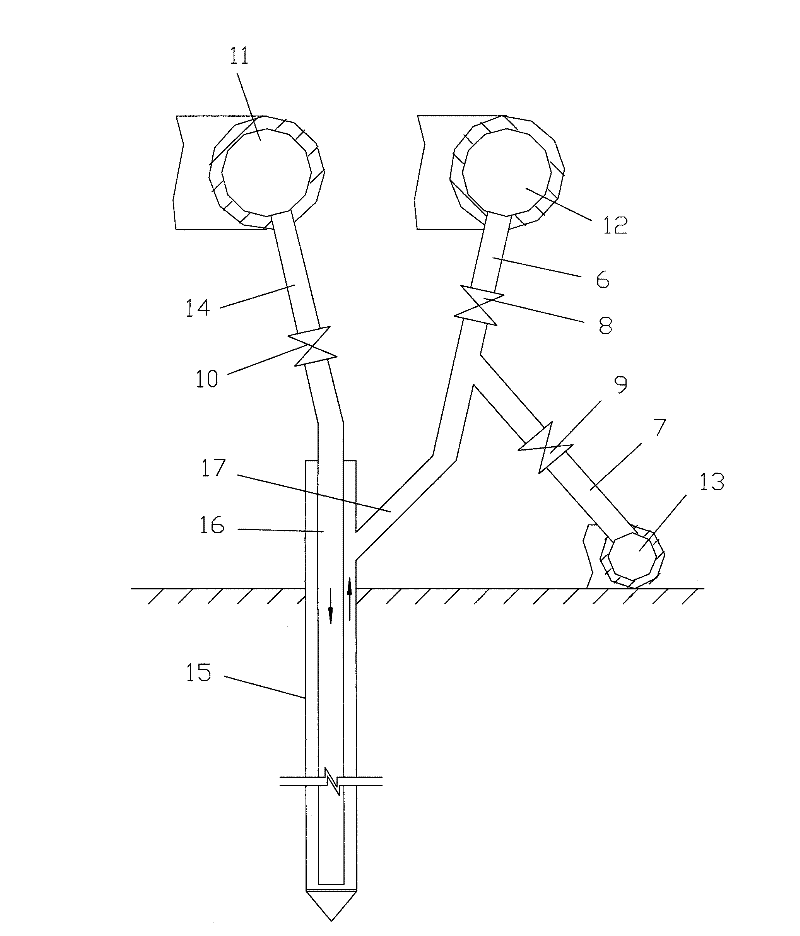

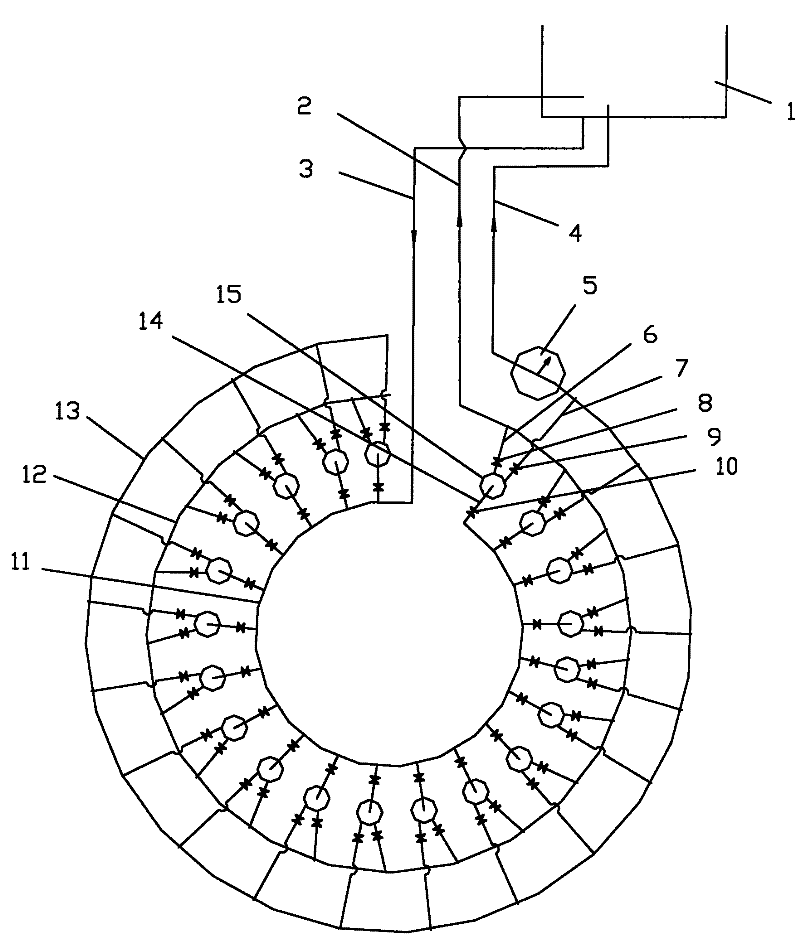

[0013] like figure 1 As shown, the vaporizer 1 is in sealing communication with the liquid distribution ring 11 through the pipeline 3, and the liquid distribution ring 11 is in sealing communication with the liquid inlet pipe 16 of each freezer 15 through the pipeline 14 and the valve 10 respectively, and the liquid outlet pipe 17 of each freezer 15 is respectively Through the pipeline 6, the valve 8 is in sealing communication with the liquid collection ring 12, and the liquid outlet pipe 17 of each freezer 15 is also in sealing communication with the detection ring 13 through the rubber pipe 7, the valve 9 respectively, and the detection ring 13 is connected with the vaporizer through the flow meter 5 and the pipeline 4 1 sealed communication. The valve 10 is a manual valve with low investment. The valves 8 and 9 are solenoid valves controlled by PLC, and the flow meter 5 is digital and electrically connected with PLC, which has a high degree of automation. The PLC is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com