Method for producing a carboxylic acid amide from a carbonyl compound and hydrocyanic acid

A technology for carbonyl compounds and carboxylic acid amides, applied in the field of preparing carboxylic acid amides, can solve problems such as poor overall efficiency, and achieve the effects of low energy use and extended service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

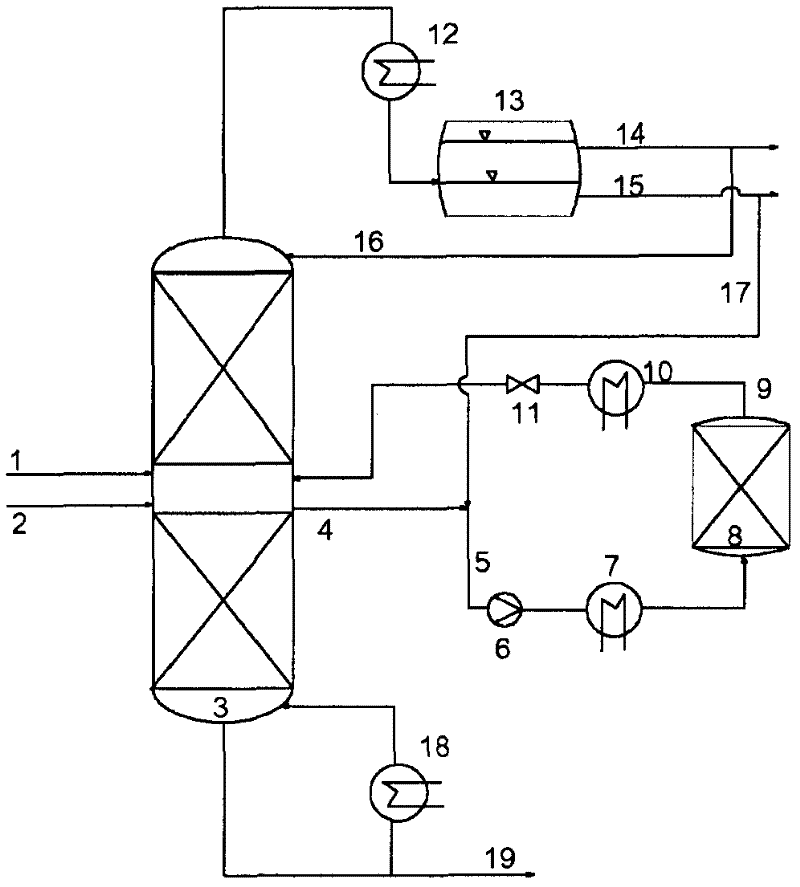

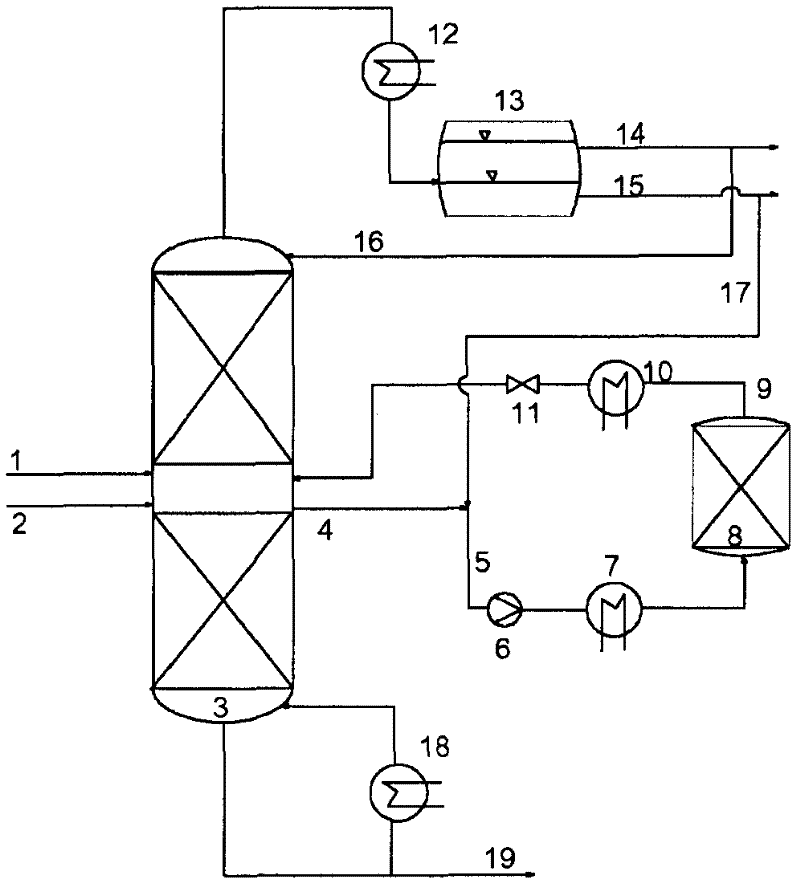

Method used

Image

Examples

Embodiment 1

[0217] Preparation contains 1mol HCN, 2.5mol acetone and 200ppm Li 2 O, and react the mixture at 20°C until equilibrium is established. The reaction mixture obtained contained 47.7% by weight of acetone cyanohydrin and 51.5% by weight of acetone. The HCN content is below 8000 ppm.

[0218] The mixture of compositions was continuously transferred to a hydrolysis reactor where 38.6% by weight of water was added. Here, the HCN content remains essentially unchanged.

[0219] Water is added partly from the reflux obtained from the bottom of the column during the purification of the reaction mixture after the hydrolysis of the acetone cyanohydrin. The hydrolysis uses MnO 2 Catalyst performed, the MnO 2 Catalysts are described in detail, for example, in WO 2008 / 061822. Air was used to stabilize the catalyst as described in Example 1 of publication WO 2008 / 061822. The pH value is 9.0.

[0220] From the reaction mixture obtained after the hydrolysis, the carboxylic acid amide i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com