Nonwoven fabric having stretchability, and process for producing the same

A manufacturing method and technology of non-woven fabrics, applied in the direction of textiles and papermaking, chemical instruments and methods, non-woven fabrics, etc., can solve the problems of damaged ventilation and stretchability, and achieve the effect of fluffy softness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

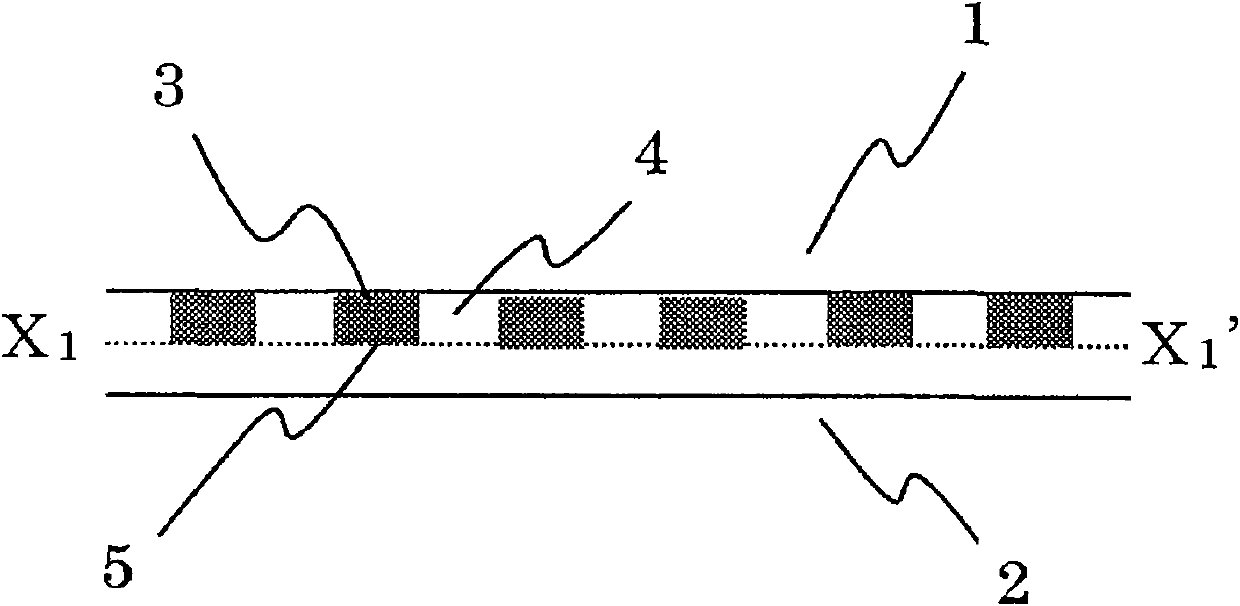

[0140] Using a side-by-side conjugate fiber (volume ratio: 50 / 50) consisting of polypropylene with a melting point of 160°C and an ethylene-propylene copolymer with a melting point of 130°C, it is produced by the carding method with a weight per unit area of 10g / m 2 Fiber layer 2. The shrinkage rate of the fiber layer 2 was 70%.

[0141] Using a concentric core-sheath composite fiber (volume ratio: 50 / 50) consisting of polypropylene with a melting point of 160°C and L-LDPE with a melting point of 100°C, it is produced by the carding method with a weight per unit area of 10g / m 2 Fiber layer 1. The shrinkage rate of the fiber layer 1 was 5%.

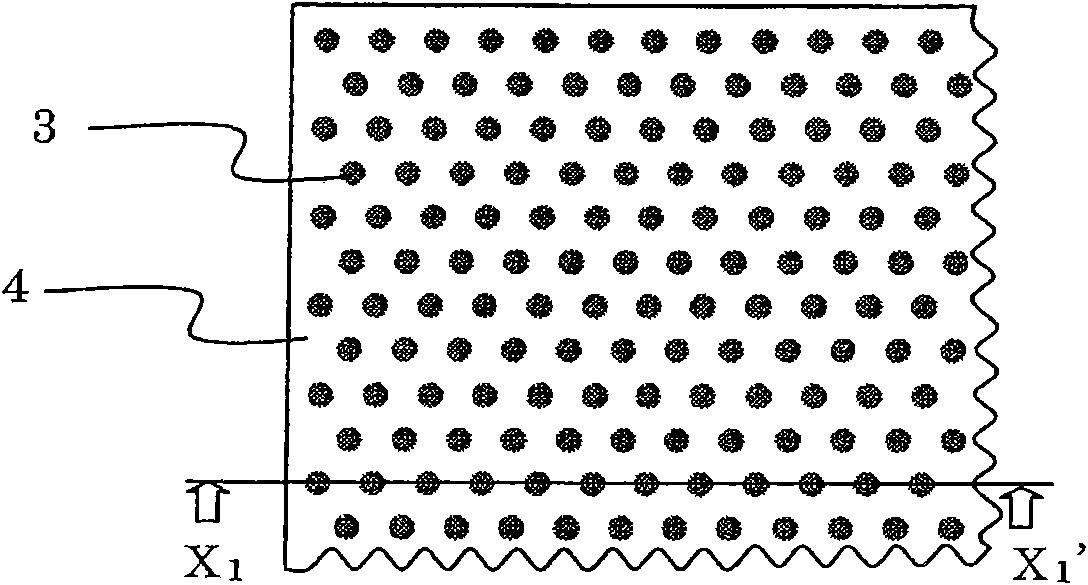

[0142] The fiber layer 1 is laminated on the fiber layer 2 so that the machine direction of each fiber layer becomes the same direction, and a two-layer web is produced. On the obtained double-layer net, a diameter of 3mm is placed on a punching plate (32.6% opening rate) that is opened in a zigzag manner at intervals of 5mm, and th...

example 2

[0145] Using a side-by-side conjugate fiber (volume ratio: 50 / 50) consisting of polypropylene with a melting point of 160°C and an ethylene-propylene copolymer with a melting point of 130°C, it is produced by the carding method with a weight per unit area of 20g / m 2 Fiber layer 2. The shrinkage rate of the fiber layer 2 was 70%.

[0146] 10% rayon was mixed in a concentric core-sheath composite fiber (volume ratio: 40 / 60) consisting of polypropylene with a melting point of 160°C and L-LDPE with a melting point of 100°C by carding, and The weight per unit area is 10g / m 2 Fiber layer 1. The shrinkage rate of the fiber layer 1 was 0%.

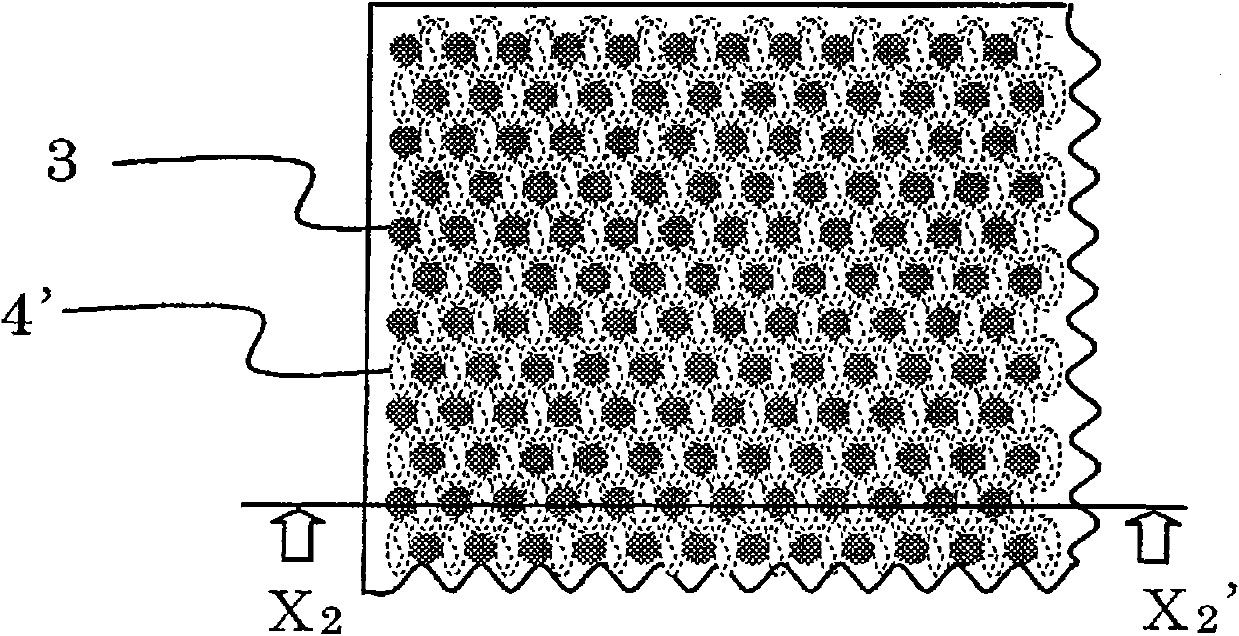

[0147] The fiber layer 1 is laminated on the fiber layer 2 so that the machine direction of each fiber layer becomes the same direction, and a two-layer web is produced. In the same manner as in Example 1, point air processing was performed on the obtained double-layer web. The shrinkage ratio at this time was 5% in MD and 3% in CD.

[014...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com