Pre-synchronization unit for transmission

A technology of pre-synchronization unit and transmission, applied in the direction of clutches, mechanical drive clutches, mechanical equipment, etc., can solve the problems of expensive and expensive manufacturing technology, and achieve the effects of durable mechanical resistance, high mechanical resistance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

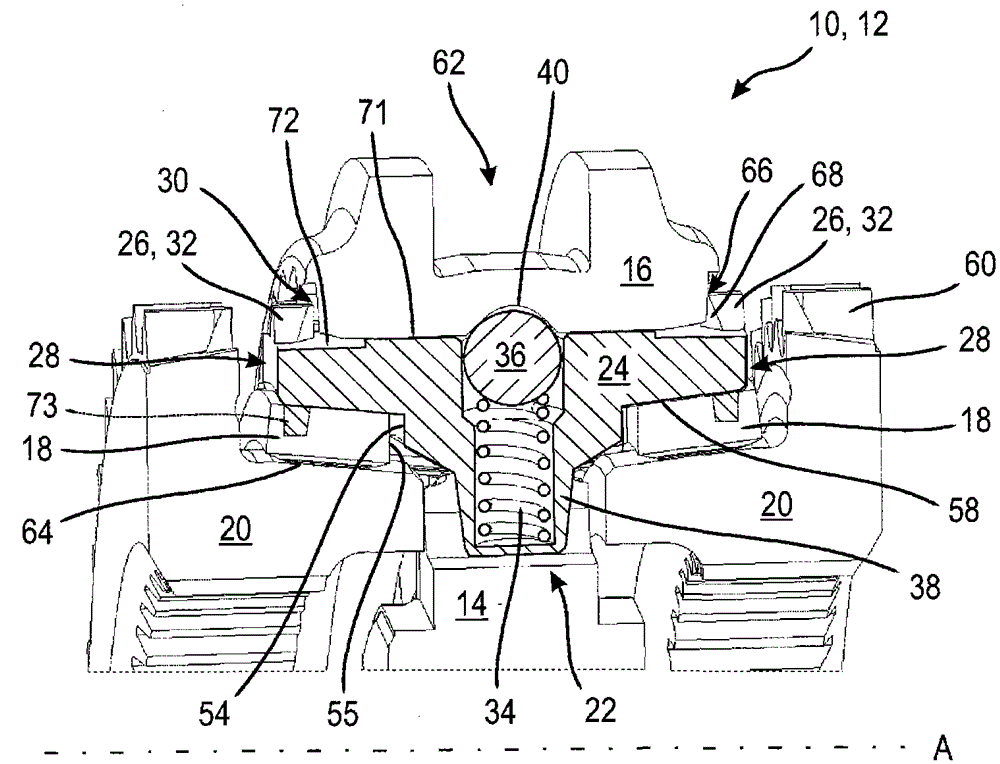

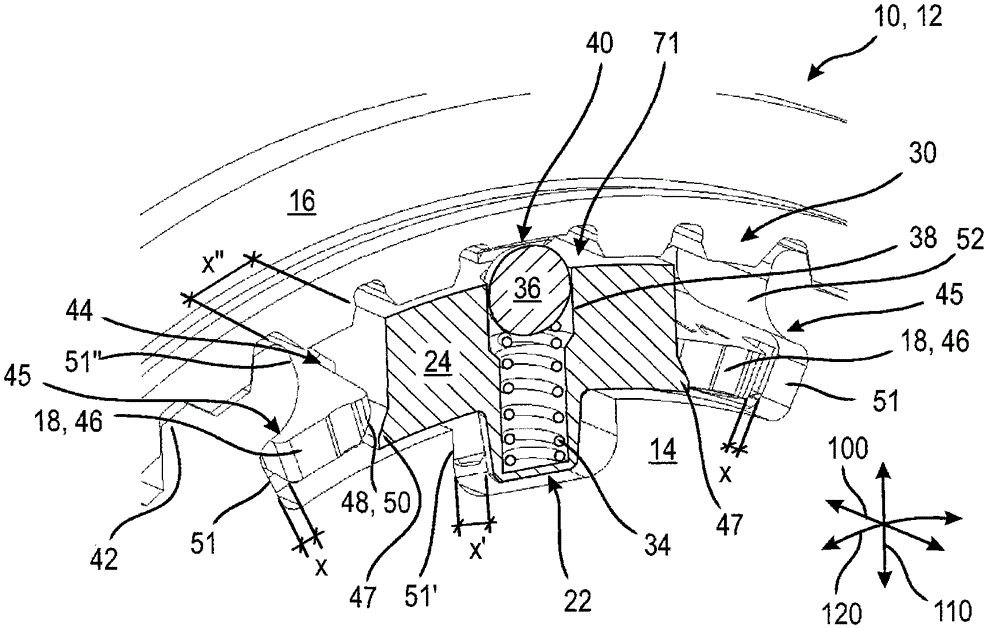

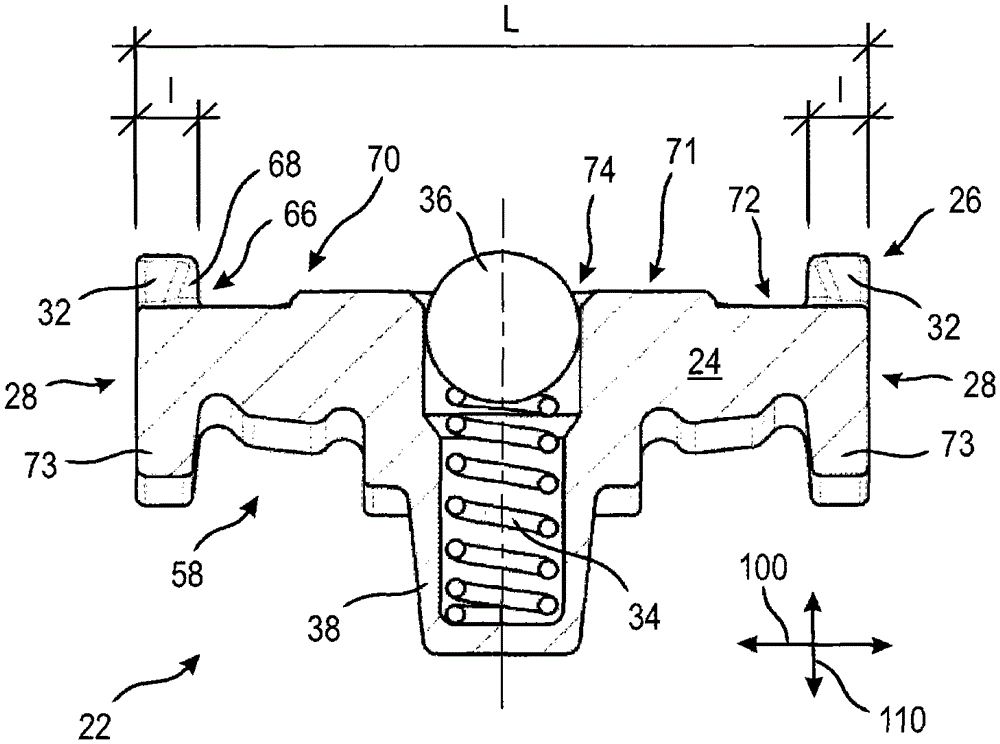

[0037] figure 1 and 2 A longitudinal or cross-sectional detail of the inertial synchronizing assembly 10 through the transmission 12 is shown. Here, the inertial synchronizing assembly 10 comprises: an annular synchronizing body 14 , which is mounted in a rotationally fixed manner on a shaft (not shown) of the transmission 12 ; a shifting sleeve 16 , which Arranged in a rotationally fixed manner relative to the synchronizing body 14 , but axially displaceable; a synchronizing ring 18 for coupling the synchronizing body 14 to a gear wheel of the transmission 12 via a frictional connection; and a presynchronization unit 22 which acts A synchronizer ring 18 is acted axially on the selector sleeve 16 and during an axial displacement of the selector sleeve 16 . here, in figure 1 The gears themselves are not shown, but only the clutch body 20 , which is connected to said gears in a rotationally fixed manner, and which has shift teeth 60 and friction surfaces 64 .

[0038] exist ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com