Control method for improving reliability of utility boiler

A technology for power station boilers and control methods, which is applied to control systems, steam generation, lighting and heating equipment, etc., can solve problems such as the safety impact of water walls, affecting the reliability of power station boilers, consuming large amounts of materials, and starting oil, etc., to achieve peeling. The effect of obvious, safe and preventing, reducing the number of movements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

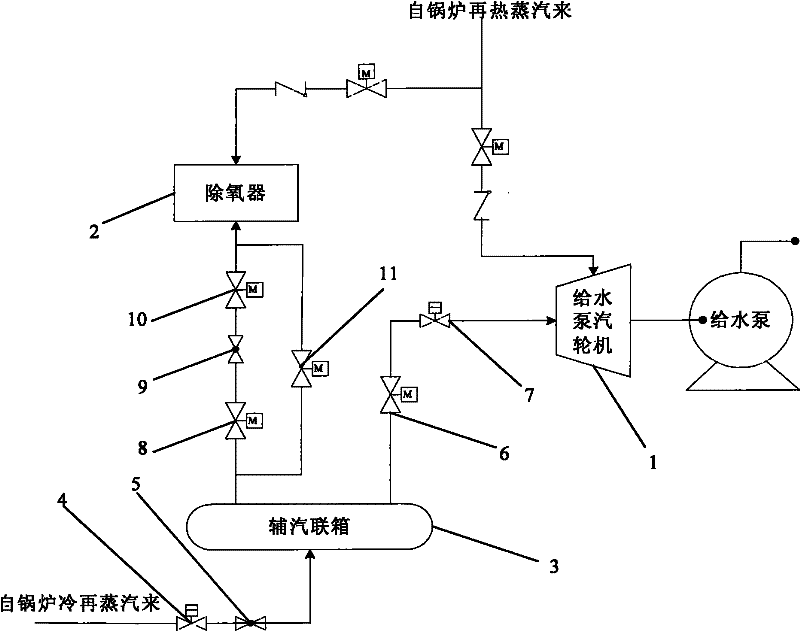

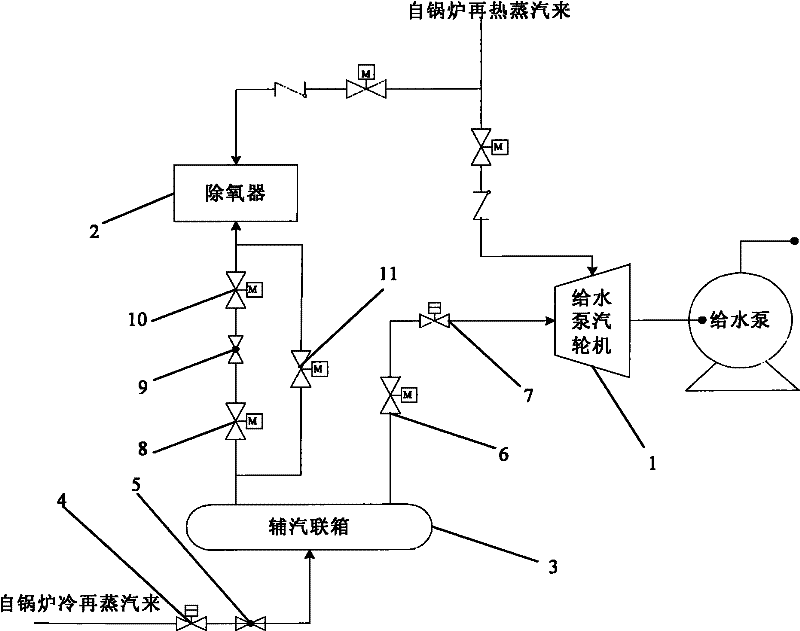

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0019] The present invention provides a control method for improving the reliability of a boiler in a power station, which is used to maintain the normal operation of the entire thermal generator set after a trip occurs in a steam turbine or a generator in a thermal power generator set so as to improve the reliability of the boiler in a power station. It is achieved through the following four aspects:

[0020] a. Retain the horizontal interlocking protection between the generator and the steam turbine in the thermal power generation unit, and cancel the horizontal interlocking protection between the generator, the steam turbine and the boiler;

[0021] Since the thermal power generation unit is designed with a bypass system, even if the steam turbine trips, after the bypass system is opened, the fuel can be quickly reduced through the boiler s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com