Liquid crystal display

A liquid crystal display and liquid crystal technology, applied in the direction of instruments, nonlinear optics, optics, etc., can solve the problems of sealing glue pollution, PI liquid backflow, etc., and achieve the effect of improving uniformity and image display quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

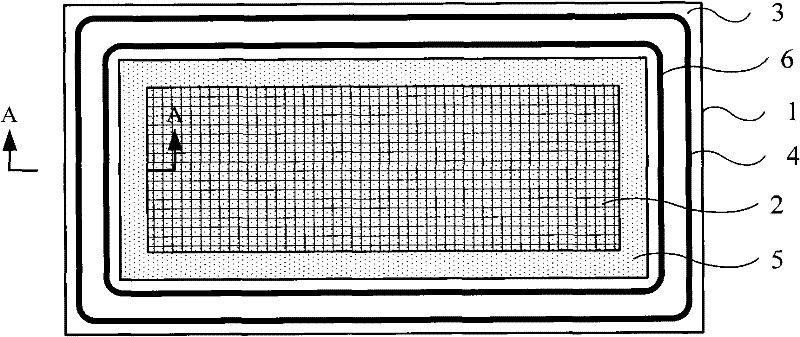

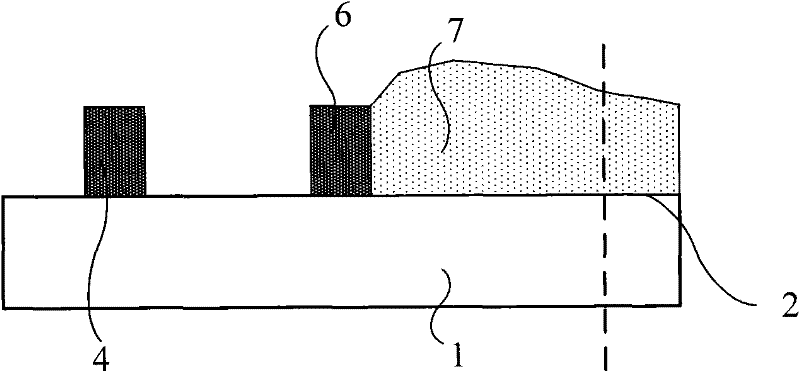

[0033] figure 2 It is a schematic top view structure diagram of the substrate in the liquid crystal display provided by Embodiment 1 of the present invention. The base substrate 1 of the liquid crystal display substrate includes a pixel area 2 and a peripheral area 3, the edge of the peripheral area 3 is formed with a sealant 4, and the predetermined alignment film pattern 5 should be covered outside the pixel area 2, and beyond a certain scope. An alignment film barrier layer 8 is formed between the pixel area 2 and the sealant 4 , and surrounds the pixel area 2 , the alignment film barrier layer 8 is composed of guardrails 9 and openings 10 spaced apart from each other. The cross-sectional shape of the guardrail 9 parallel to the base substrate 1 is a straight line segment. The width of each guardrail 9 is the same, and the width of each opening 10 is also the same, and the guardrails 9 and the openings 10 are evenly spaced.

[0034] The alignment film liquid is arranged...

Embodiment 2

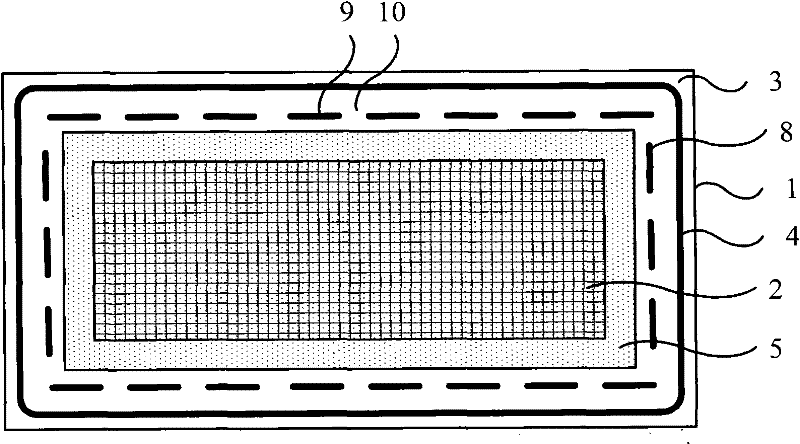

[0037] Figure 3A It is a schematic top view structure diagram of the substrate in the liquid crystal display provided by Embodiment 2 of the present invention, Figure 3B for Figure 3A The schematic diagram of the side view section structure along the B-B line, Figure 3C for Figure 3A Schematic diagram of the cross-sectional structure in side view along the line C-C. This embodiment is based on Embodiment 1, the difference is that the liquid crystal display substrate includes a plurality of alignment film barrier layers 8, specifically two alignment film barrier layers 8, and each alignment film barrier layer 8 includes guardrails 9 arranged at intervals and opening 10. Among the two adjacent alignment film barrier layers 8 , the opening 10 of one alignment film barrier layer 8 overlaps with the guardrail 9 of the other alignment film barrier layer 8 to effectively block the diffusion of PI liquid 7 .

[0038]With the technical solution of this embodiment, the PI liqu...

Embodiment 3

[0040] Figure 4 The top view structural diagram of the substrate in the liquid crystal display provided by the third embodiment of the present invention, this embodiment is based on the second embodiment, the difference is that it includes a plurality of alignment film barrier layers 8 , specifically three. The openings 10 and guardrails 9 in two adjacent alignment film barrier layers 8 are overlapped, and the length of the guardrails 9 in each alignment film barrier layer 8 gradually increases in the direction from the pixel region 2 to the sealant 4 .

[0041] In a specific application, more PI liquid will flow from the alignment film barrier layer adjacent to the pixel area, and wider openings are required to better prevent backflow. After passing through multiple alignment film barrier layers, the amount of PI liquid diffused will decrease, and the width of the opening can be gradually narrowed. By setting openings with gradually narrowing widths, it is possible to effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com