High-energy storage and high-density power electronic capacitor

A technology for power electronics and capacitors, which is applied in the field of high energy storage and high density power electronic capacitors, can solve the problems of capacitor voltage resistance and high current resistance that are difficult to meet the requirements of electric vehicle capacitors, etc. The effect of good pressure and high current resistance performance and small overall volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

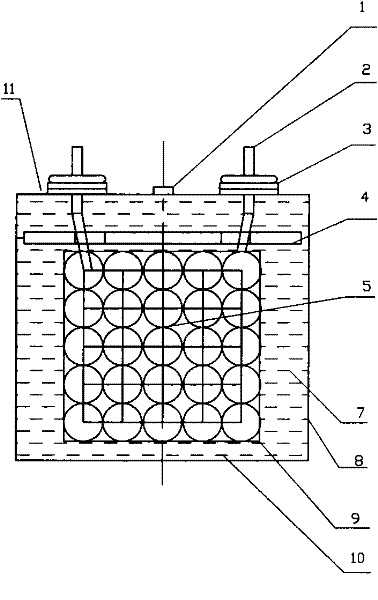

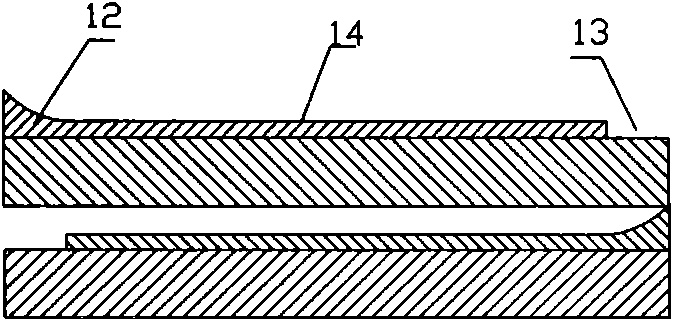

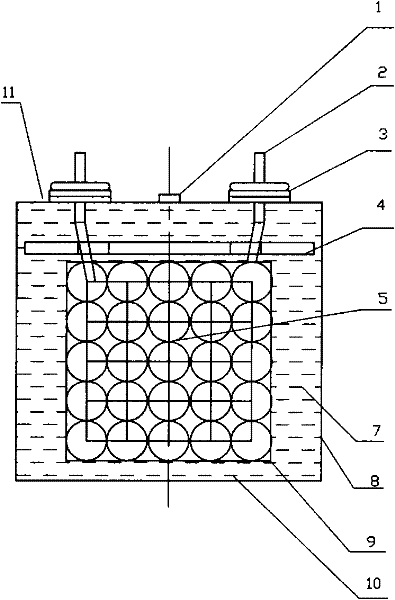

[0010] Embodiment: The present invention consists of a metal shell 8, a lead-out 2, an insulating seat 3, a capacitor core group 5, a cover plate 11, a positioning epoxy plate 4, and an impregnating agent 7, and an oil injection hole 1 is provided on the cover plate 11. Several parallel or parallel capacitor core groups 5 assembled in the casing 8 are formed by winding a thin film with a single-side margin 13 and a single-side metal layer thickening region 12 . The capacitor core group 5 is wrapped up with an insulating package 9, and green shell paper 10 is put into the bottom of the shell. Choose a film with a margin of 2.5mm on one side and a resistance value of 12 squares in the metallized thickened area on one side between 2-4 ohms / square, and a resistance value of 14 squares in the non-thickened area of the metal layer between 5.5-9.5Ω / square between. Two layers of metallized films with different edge directions are superimposed and wound in parallel to form a single ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com