High-efficiency and low-nitrogen finishing pig feed

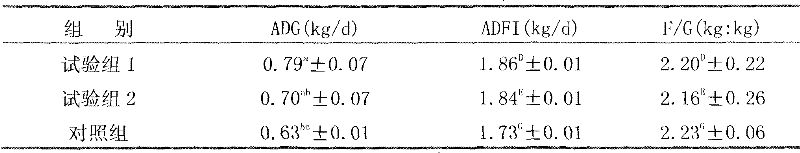

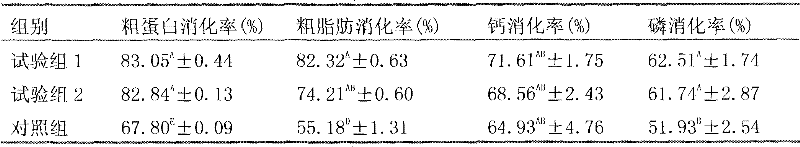

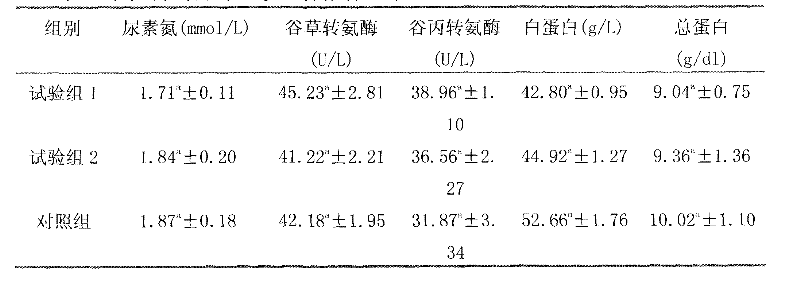

A high-efficiency technology for fattening pigs, applied in the field of feed for fattening pigs, can solve the problems of heavy environmental pollution and high ammonia content in pig excrement, achieve the effects of reducing excretion, improving utilization rate, and reducing feeding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 76.4kg of corn, 5kg of bran, 14.6kg of soybean meal, 4kg of premix, 0.1594kg of lysine, and 0.003kg of methionine.

[0017] The corn, bran, and soybean meal are superfinely pulverized, and after the pulverized materials are evenly mixed, the premix, lysine, and methionine are added and mixed evenly.

Embodiment 3

[0019] Corn 70.5kg, bran 5.2kg, soybean meal 18kg, fish meal 2kg, soybean oil 0.3kg, premix 4kg, lysine 0.1871kg, methionine 0.03258kg.

[0020] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com