Welding arm lifting device

A lifting device and welding arm technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of high cost, large processing volume, complex structure, etc., achieve simple processing, simple structure, and reduce production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific drawings and embodiments.

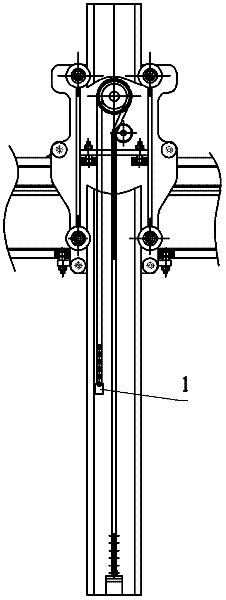

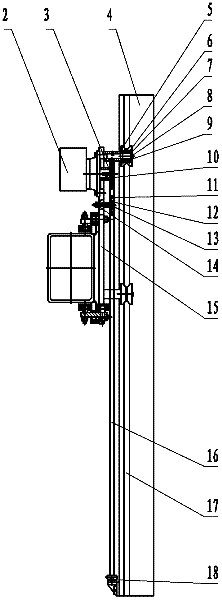

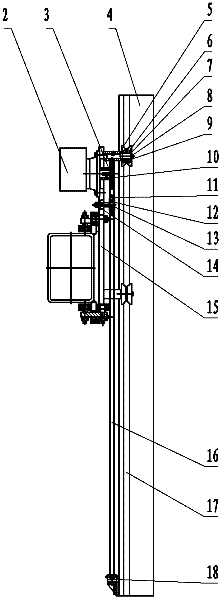

[0012] The present invention mainly consists of a chain counterweight 1, a reducer 2, a main sprocket 3, a welding arm 4, a lifting guide wheel 5, a bearing 6, a shaft 7, a nut 8, a cover plate 9, a set screw 10, and a secondary sprocket 11 , bearing 12, axle 13, nut 14, plank 15, chain 16, round steel 17 and chain holder 18 etc. are formed.

[0013] In the present invention, the round steel 17 is welded on the welding arm 4, the reducer 2 and the shaft 7 are installed on the carriage 15 respectively, the lifting guide wheel 5 is installed on the shaft 7, and the lifting guide wheel 5 is equipped with a bearing 6 , for supporting axis 7. The main sprocket 3 is fixed on the reducer 2 through the set screw 10, the shaft 13 is fixed on the carriage 15 through the nut 14, the secondary sprocket 11 is installed on the shaft 13, and the bearing 12 is installed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com