Production method of anti-sand sieve tube

A production method and sand control screen technology, which is applied in the field of petroleum production engineering, can solve the problems of low production efficiency, low yield, labor-intensive, etc., and achieve the effects of high degree of automation, high production efficiency and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Label in the figure

[0048]

[0049]

[0050] The present invention is a kind of production method of sand control screen pipe, and this method comprises the following steps,

[0051] Step 1. Prepare materials and purchase three kinds of raw materials:

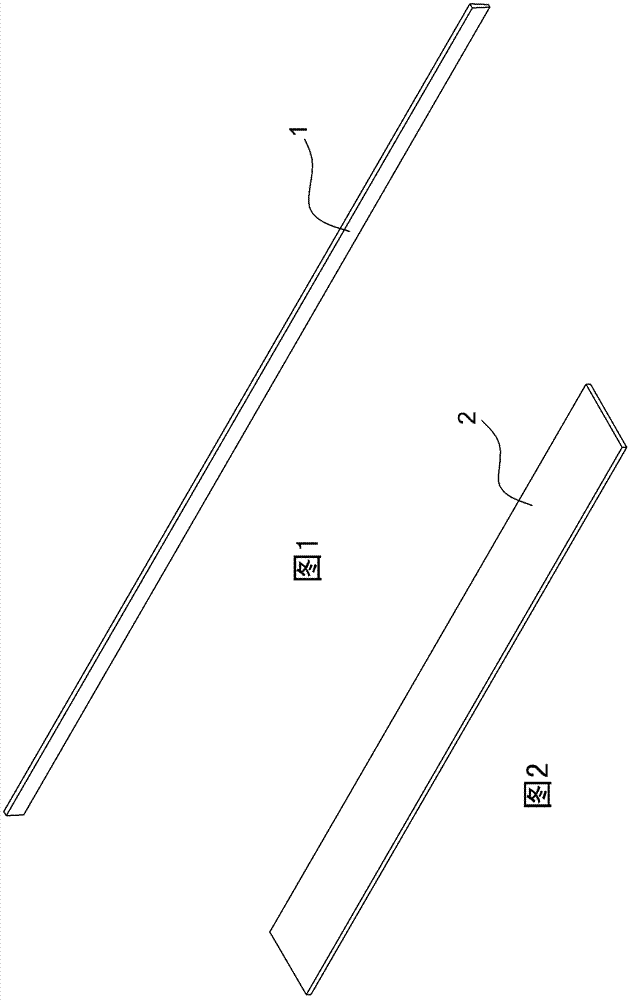

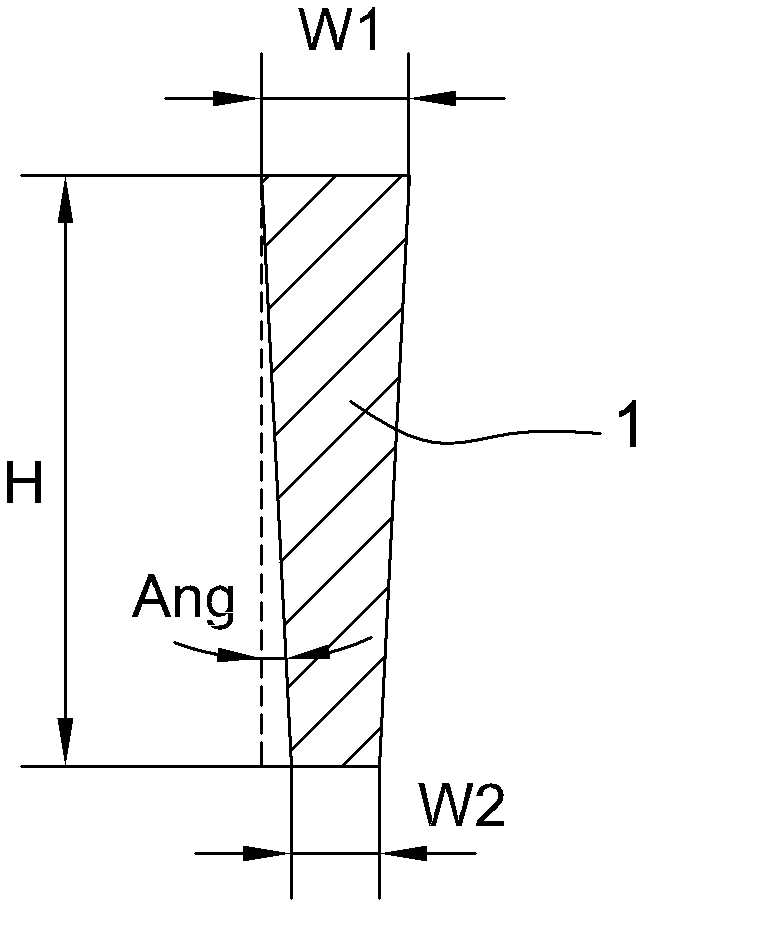

[0052] The first is a trapezoidal stainless steel wire 1, which is used to produce filter sheets, such as figure 1 , image 3 As shown, the stainless steel wire 1 is wide at the top and narrow at the bottom, the upper width W1 is 1-1.5mm, the lower width W2 is 0.6-1mm, and the height H is 3-7mm. The value ranges of the upper width W1, the lower width W2, and the height H should be Ensure that the cone angle Ang of the stainless steel wire 1 is between 1 degree and 30 degrees, and the model of the stainless steel is S304.

[0053] The second is a strip-shaped stainless steel plate 2 such as figure 2 As shown, for the production of the protective cover, the strip-shaped stainless steel plate 2 has a thickness ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com