Electromagnetic shielding adhesive tape

A technology of electromagnetic shielding and electromagnetic shielding layer, applied in the fields of magnetic field/electric field shielding, adhesives, electrical components, etc., can solve the problems of tearing, affecting the electrical conductivity and electromagnetic shielding effect of products, affecting the use of products, etc., to achieve good peeling force, The effect of good electromagnetic shielding efficiency and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] Tape preparation:

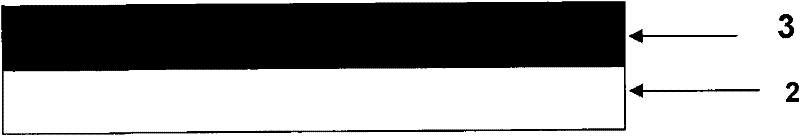

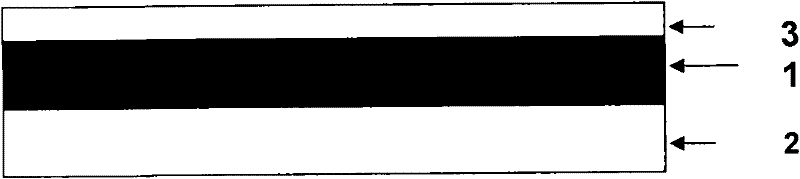

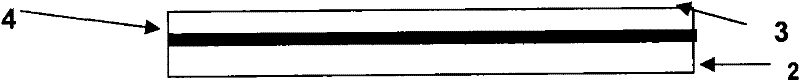

[0062] Mix acrylate raw gum, ethyl acetate, tackifying resin, and cross-linking agent evenly, then spread it on silicone oil-coated kraft paper, and dry it to make a pressure-sensitive adhesive tape with a thickness of 1.2mils (30μm) spare. Take part of the above-mentioned adhesive tape, and use the magnetron sputtering coating (sputtering) process to deposit a layer of conductive metal on the surface of the adhesive tape (non-release paper surface) for later use. The order of sputtering is: nickel, silver, nickel, the thickness of each layer They are: 30nm, 80nm, 25nm, and the total thickness of the sputtered metal is 135nm. Take another part of the above-mentioned adhesive tape, attach its non-release paper surface to 1.5mils (38μm) PET film, and peel off the original release paper at the same time. Then, the adhesive surface after peeling off the release paper is bonded to the above metal surface, and finally the required electromagnetic shieldi...

Embodiment 2

[0069] Tape preparation:

[0070] Mix acrylate raw gum, ethyl acetate, tackifying resin, and crosslinking agent evenly, and then spread it on silicone oil-coated kraft paper, and dry it to make a pressure-sensitive adhesive tape with a thickness of 0.5 mils (13 μm) spare. Take part of the above-mentioned adhesive tape, and use the magnetron sputtering coating (sputtering) process to deposit a layer of conductive metal on the surface of the adhesive tape (non-release paper surface) for later use. The order of sputtering is: nickel, copper, nickel, the thickness of each layer They are: 40nm, 100nm, 50nm, and the total thickness of the sputtered metal is 190nm. Take another part of the above-mentioned adhesive tape, attach its non-release paper surface to 0.5mils (13μm) PET film, and peel off the original release paper at the same time. Then, the adhesive surface after peeling off the release paper is bonded to the above metal surface, and finally the required electromagnetic s...

Embodiment 3

[0077] Tape preparation:

[0078] Mix acrylate raw rubber with ethyl acetate, tackifying resin, and crosslinking agent evenly, and then spread it on silicone oil-coated kraft paper, and dry it to make a pressure-sensitive adhesive tape with a thickness of 2.0mils (50μm) spare. Take part of the above-mentioned adhesive tape, and deposit a layer of conductive metal nickel on the surface of the adhesive tape (non-release paper surface) by using a magnetron sputtering coating (sputtering) process, with a thickness of 20nm. Take another part of the above-mentioned adhesive tape, attach its non-release paper surface to 1.0mils (25μm) PET film, and peel off the original release paper at the same time. Then, the adhesive surface after peeling off the release paper is bonded to the above metal surface, and finally the required electromagnetic shielding tape is obtained. The total thickness of the produced tape was 125 μm.

[0079] Performance Testing:

[0080] The adhesion (adhesio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com