Method for reinforcing transmission line iron tower

A technology for transmission line iron towers and pulling wires, which is applied in the direction of towers, building maintenance, building types, etc., can solve the problems of increasing the load weight of transmission line iron towers, increasing the total weight of reinforcement materials, and requiring high node processing, so as to achieve the weight of the poles. , the same appearance, fast construction speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

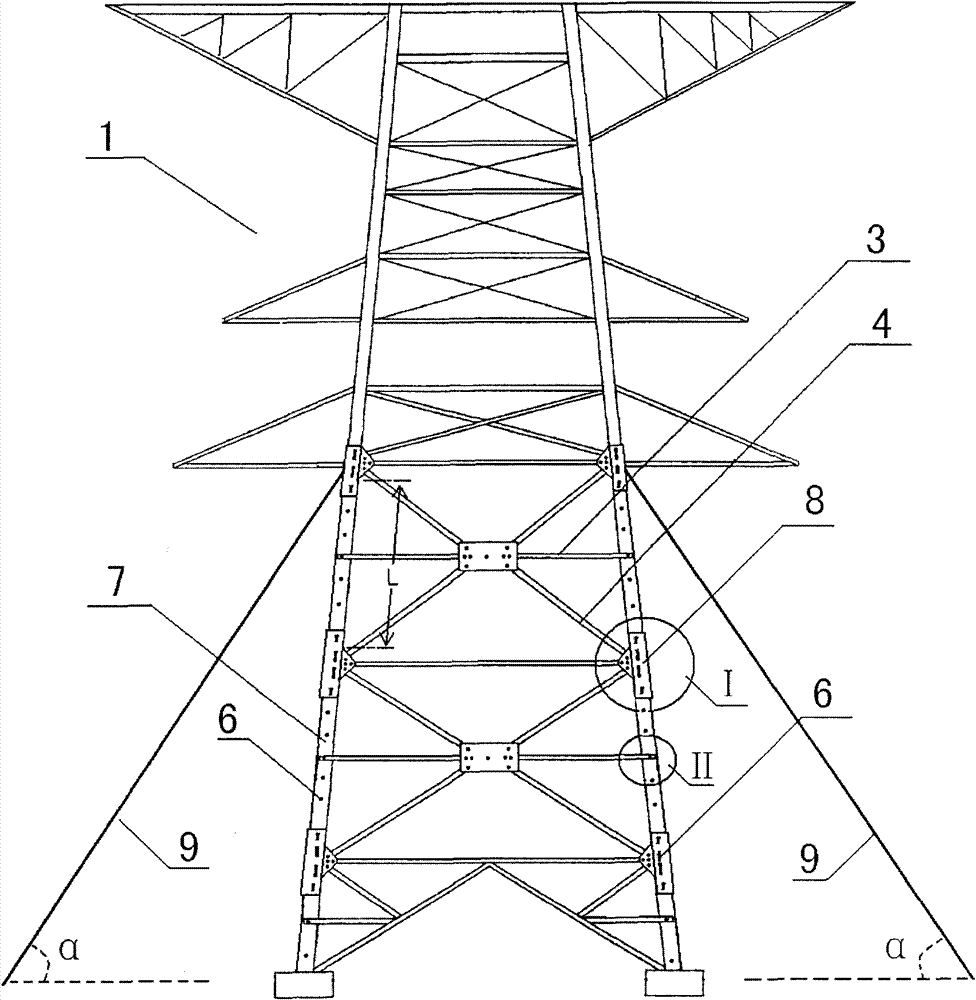

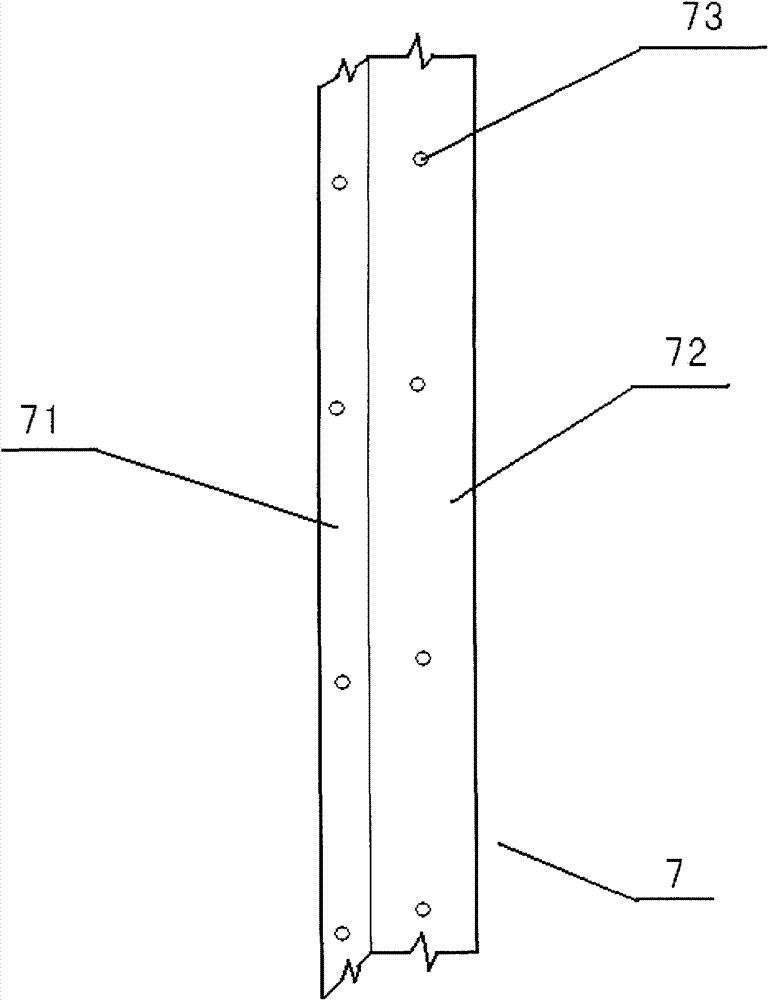

[0044] The method for strengthening the iron tower of the transmission line of the present invention is a method for reinforcing the original main material of the iron tower of the transmission line by adding corresponding newly added components on the basis of the original main material of the iron tower of the transmission line.

[0045] Preferred embodiments of the present invention will be described below with reference to the drawings.

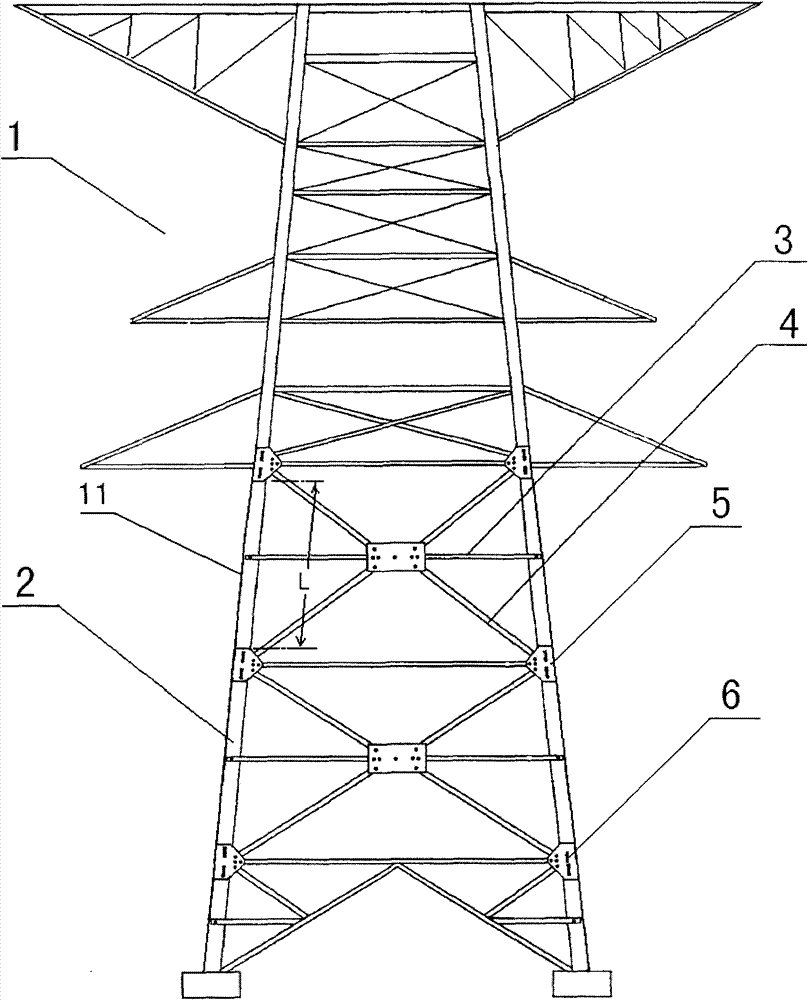

[0046] figure 1 It is a schematic diagram of the structure of the transmission line tower before reinforcement. The transmission line iron tower 1 is a tower frame structure composed of main materials 11 , cross members 3 , oblique members 4 , gusset plates 5 , and fastening bolts 6 . The transverse material 3 and the oblique material 4 are installed together with the main material 11 by fastening bolts 6 through the gusset plate 5 , or the horizontal material 3 and the oblique material 4 are directly installed together with the main mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com