Gelled honeycomb composite board

A technology for gelatinizing bees and composite boards, which is applied to chemical instruments and methods, paper/cardboard layered products, textiles and papermaking, etc. The effect of transportation cost, high plasticity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

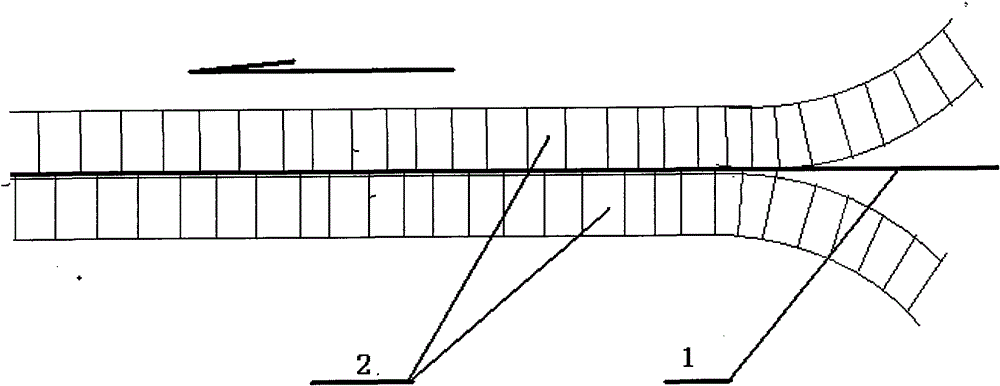

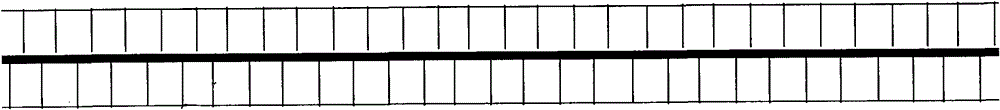

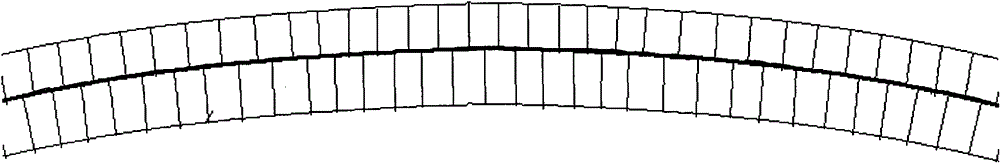

Method used

Image

Examples

experiment example 1

[0044] Gelled honeycomb high thermal insulation exterior wall: the gelled honeycomb composite board produced by the above-mentioned production process, the gelling agent adsorbed by the honeycomb core is a waterproof gelling agent that has been publicly produced and sold on the market, and the gelled honeycomb composite board contains four layers ( or six layers) waterproof gelled honeycomb core, and the panels are made of materials with good waterproof and weather resistance, such as mud fiberboard (aluminum-plastic board), to meet the mechanical and weather resistance requirements of the outer wall. The inner space of the honeycomb is filled with different thermal insulation fillers to ensure the high thermal insulation requirements of different use environments.

[0045]Requirements for the use of exterior walls of modern frame buildings: Although the walls are non-load-bearing walls, they must be able to resist various complex climate environments (wind, snow, snow, sun exp...

experiment example 2

[0047] The gelled honeycomb fireproof material is a gelled honeycomb composite board produced by the above-mentioned production process. The glue adsorbed by the honeycomb core is a fireproof glue that has been publicly produced and sold on the market. The gelled honeycomb core can have two, four, or six layers; Good panel: the interleaved paper is fireproof glued paper; experiments have proved that when fire occurs, the fireproof glue adsorbed on the honeycomb will start to foam and carbonize, and the foaming rate will be hundreds of times, forming inorganic foam such as carbon airgel Carbon, filling the honeycomb space. At the same time, the foaming process of the fireproof glue decomposes strong acid substances, dehydrating the paper fibers to form non-combustible and hard inorganic carbon. In this way, the inorganic foam carbon fills the first layer of honeycomb space first, blocking heat transfer , to ensure the safety of the second layer of honeycomb, if the surrounding b...

experiment example 3

[0049] Mobile firewall: use fireproof gelled honeycomb core, which can be two, four, or six layers; the panel is replaced with only a few layers of cardboard that has been soaked and pasted by fireproof gelatinization, and is used as a board for blocking and separating fire zones It is called a mobile firewall. When a fire occurs, it is used as a fire-fighting product to block the fire area. It is not only very light (only three to five kilograms per square meter with a thickness of 100mm). And the fire prevention effect is much better than thick inorganic panels. Although it is non-combustible, it has a high heat transfer coefficient and is easy to crack and shatter at high temperatures. However, multi-layer fireproof glued paper foams layer by layer when exposed to fire, forming a bubble layer between the base material and the flame, which greatly improves the thermal resistance. layer thickness.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com