Method for testing dynamic thermal balance of steel rolling industrial furnace

A test method and technology of an industrial furnace, applied in the field of testing, can solve problems such as the inability of heat balance data to reflect, and achieve the effect of continuous and comprehensive calculation results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In order to facilitate the understanding and implementation of the present invention by those of ordinary skill in the art, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments.

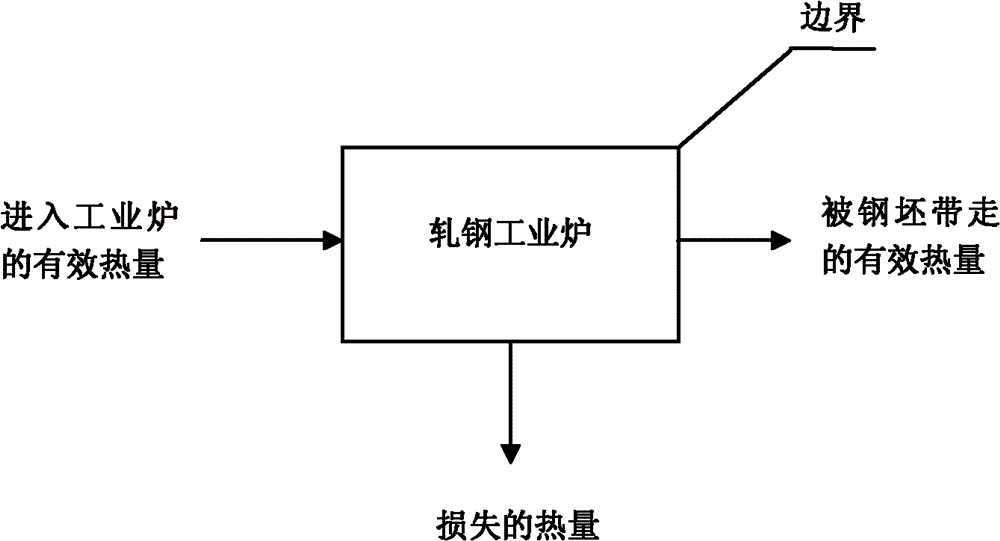

[0065] like figure 1 Shown is the heat balance block diagram of the steel rolling industrial furnace. The supply heat of the steel rolling industrial furnace is mainly the chemical exotherm generated by the combustion of fuel, and the effective heat is the physical heat taken away by the heated billet, and the heat taken away by the flue gas and the loss of the furnace wall is the heat. loss, from figure 1 It can be seen that there is an energy balance relationship among the three.

[0066] That is: the effective heat entering the industrial furnace = the effective heat taken away by the billet + the lost heat

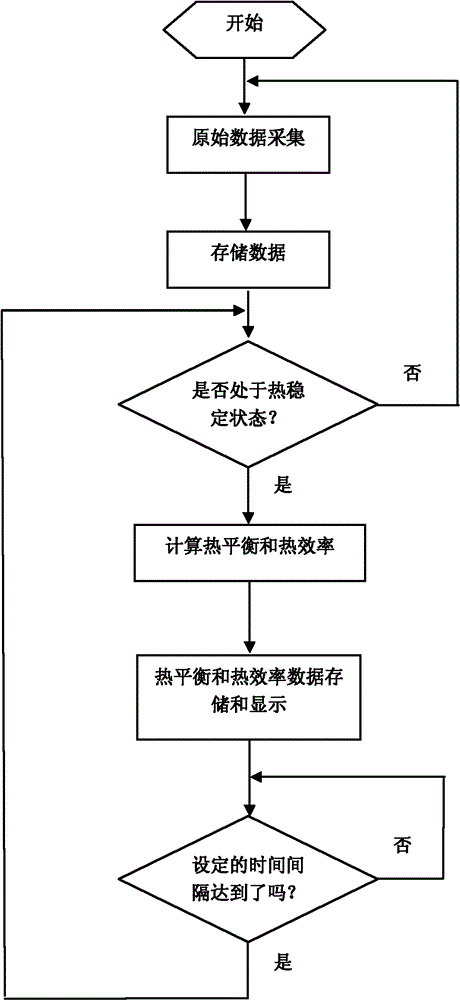

[0067] figure 2 It is the flow chart of dynamic thermal balance test and calculation.

[0068] Firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com