On-line monitor of incomplete combusting loss of machines

A technology of complete combustion and monitoring instrument, which is used in fuel testing, instruments, analysis materials, etc., can solve the problems of no way to measure, the volume of the resonant cavity is large, and the loss of incomplete combustion cannot be measured online, so as to improve the measurement accuracy, The effect of similar bulk density and uniform particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

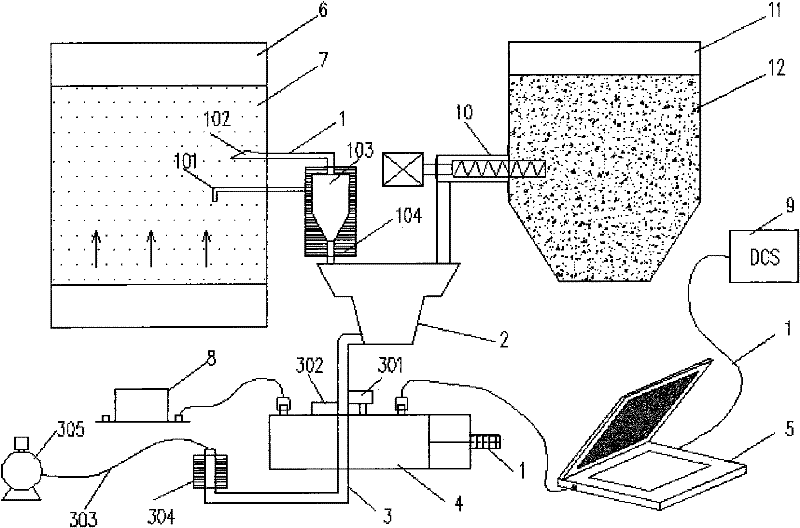

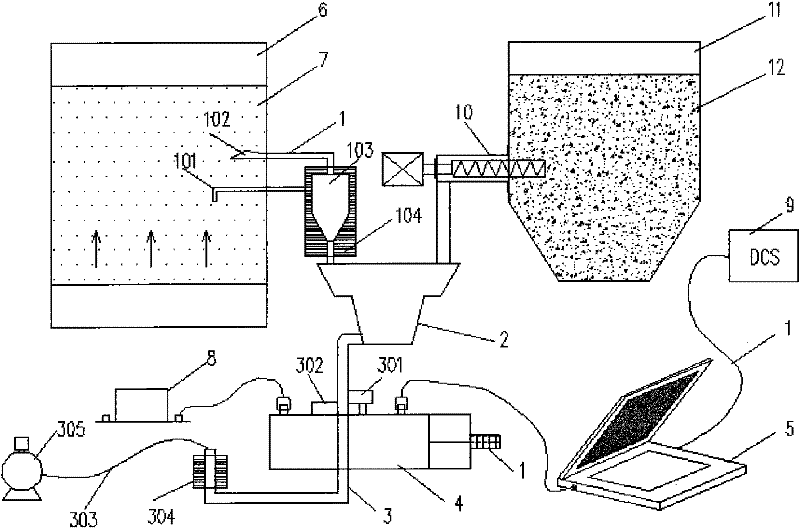

[0020] Such as figure 1 As shown, the present embodiment includes: sampler 1, grinding device 2, ash sample tube 3, measuring cavity 4 and main frame 5, wherein: sampler 1 is installed in tail flue 6, sampler 1 and grinding device 2 are connected, and grinding The device 2 is connected to the ash sample pipe 3, and the fly ash 7 extracted from the tail flue 6 is processed by the grinding device 2 and sent to the ash sample pipe 3 for measurement. The microwave signal of the measurement cavity 4 comes from the signal source 8, and the measured signal is transmitted to the host computer 5. By communicating with the DCS system 9, relevant information is obtained, and the measured fly ash carbon content signal is calibrated to obtain the fly ash content. Carbon content, and calculate the corresponding mechanical incomplete combustion loss.

[0021] In this embodiment, the grinding device added between the sampler 1 and the ash sample tube 3 can grind different small fly ash parti...

specific Embodiment approach 2

[0022] Such as figure 1 As shown, the present embodiment comprises: spiral sampler 10, grinding device 2, ash sample tube 3, measuring cavity 4 and main frame 5, wherein: sampler 10 is installed in ash hopper 11, sampler 10 is connected with grinding device 2, The grinding device 2 is connected to the ash sample pipe 3, and the ash 12 extracted from the ash hopper 11 is processed by the grinding device 2 and sent to the ash sample pipe 3 for measurement. The microwave signal of the measurement chamber 4 comes from a signal source 8 , and the measured signal is transmitted to the host computer 5 . By communicating with the DCS system 9, relevant information is obtained, and the measured carbon content signal of the ash is calibrated to obtain the carbon content of the ash, and the corresponding mechanical incomplete combustion loss is calculated.

[0023] This embodiment changes the current situation that the carbon content of the ash can only be measured by off-line sampling,...

specific Embodiment approach 3

[0024] Such as figure 1 As shown, this embodiment includes: a sampler 1 , a grinding device 2 , an ash sample tube 3 , a measuring chamber 4 , and a host 5 . Among them, the sampler 1 adopts an unpowered self-sampling device, including a sampling gun 101, an ejector gun 102 and a cyclone separator 103. At the boiler tail flue 6, the negative pressure is relatively large, and the ejector gun with the flared mouth carrying the incoming flow is adopted. 102 can generate a large negative pressure, so that the cyclone separator 103 is in a negative pressure state. Under the action of negative pressure, the sampling gun extracts the fly ash 7 in the tail flue 6, and separates it into the grinding device 2. Wrapped in the cyclone The heating belt 104 outside the device 103 can keep the temperature of the device above 150° C., away from the dew point, and ensure that the fly ash obtained by sampling is in a dry state.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com